About Us

Shandong Huatong Hydraulic Machinery Co., Ltd (Hereinafter referred to as “Shandong Huatong”)

Founded in 2008 and located in Gaotang, Shandong Province, Shandong Huatong is a technology-based enterprise specializing in the design, research & development, manufacturing, and sales of large-scale industrial solid waste comprehensive utilization equipment.

The company provides a full range of products including fully automatic block molding intelligent production lines, fully automatic static pressing forming machine production lines, vertical shaft planetary mixing stations, as well as customized solid waste utilization solutions, project planning, and operation services.

Shandong Huatong has several member companies — Huatong Machinery, Avant Machinery, Darun Environmental Protection, and Côte d’Ivoire Shandong Group — and employs over 270 engineers and technicians.

The enterprise has passed GB/T9001-2016 / ISO9001-2015 Quality Management System Certification and has won the Shandong Provincial Circular Economy Science and Technology Award.

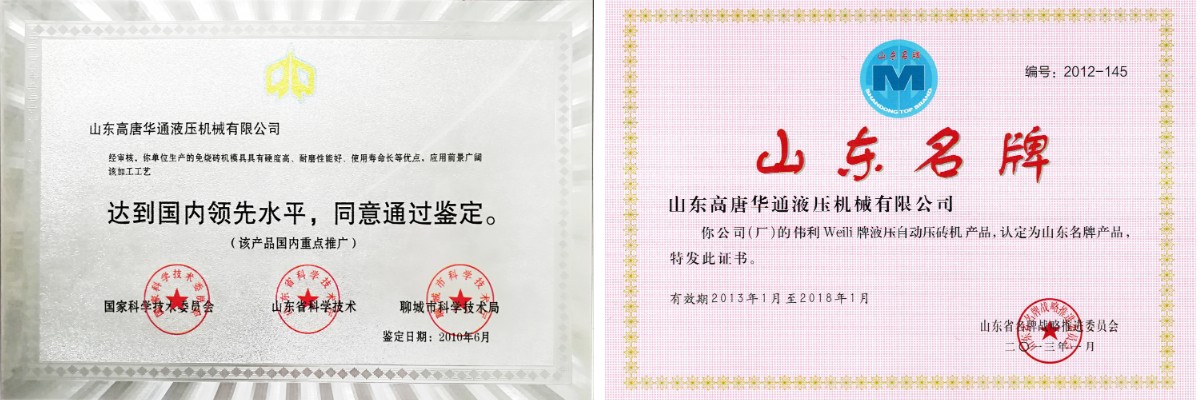

(II) Corporate Honors

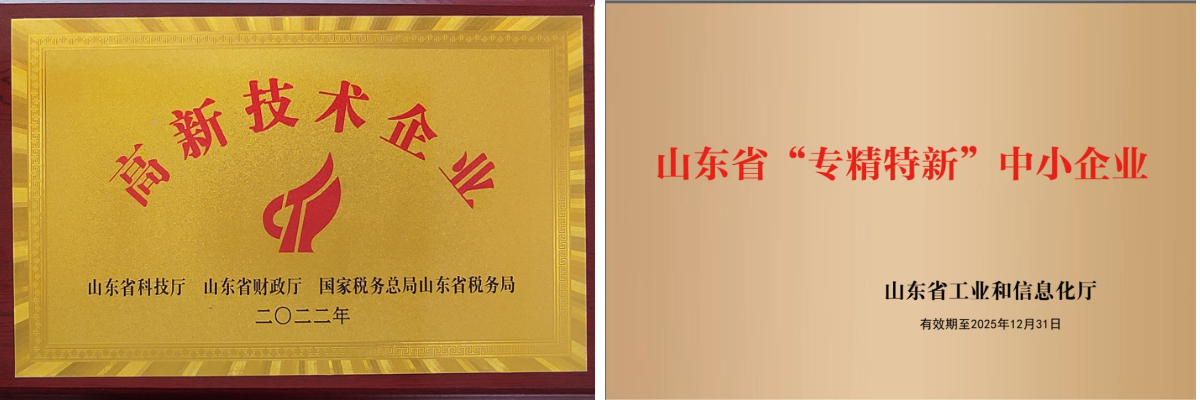

The company has successively received multiple national and provincial-level recognitions:

Awarded the “Domestic Leading Level Certification” by the National Science and Technology Commission;

Recognized as a “High-Tech Enterprise” by the Shandong Provincial Department of Science and Technology;

Granted the First (Set) Major Technical Equipment Certificate and “Specialized, Refined, Distinctive, and Innovative (SRDI)” Enterprise title by the Shandong Provincial Department of Industry and Information Technology;

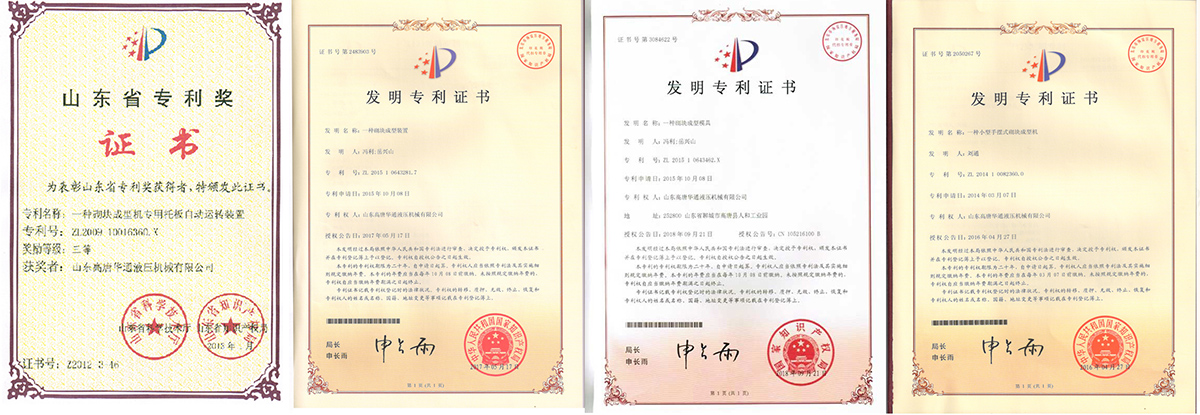

Received the Shandong Provincial Patent Award from the Shandong Provincial Department of Science and Technology;

Named a “Shandong Famous Brand” by the Shandong Provincial Brand Strategy Promotion Committee;

Recognized as “Mechanical Equipment Engineering Technology Research Center” and “Municipal Industrial Design Center” by the Liaocheng Science and Technology Bureau;

Serves as a member of the National Building Materials Industry Standards Committee and has been certified as a National Compliant Product in the Building Materials Machinery Industry.

Its R&D achievements were included in the 2022 Ministry of Ecology and Environment “Catalogue of Advanced and Applicable Technologies for the Construction of Zero-Waste Cities (Second Batch)”, as well as in the 2023 “Catalogue of Advanced Water- and Energy-Saving and Environmentally Friendly Technologies and Equipment in the Industrial Sector of Shandong Province.”

The company also serves as:

Vice President Unit, Solid Waste Comprehensive Utilization Branch of the China Building Materials Market Association;

Executive Director Unit, China Bulk Cement Development Association;

Vice President Unit, Geopolymer Cement and Green Building Materials Committee of the China Bulk Cement Development Association.

Shandong Huatong holds 6 national invention patents and 20 utility model patents, and has been awarded:

“National Outstanding Contribution Enterprise in Solid Waste Utilization (2022)”;

“Third Prize for Scientific and Technological Innovation in Equipment Manufacturing, Shandong Province (2022)”;

“Third Prize for Circular Economy Science and Technology, Shandong Province (2022)”;

“Demonstration Unit for New Waste-Utilization Materials” and “Emerging Industry Leader” (2020–2021);

“Famous Brand” and “Technological Innovation Enterprise” in the Bohai Rim Building Materials Industry (2021).

(III) Huatong Intelligent Waste-Utilization Fully Automatic Brick Production Line

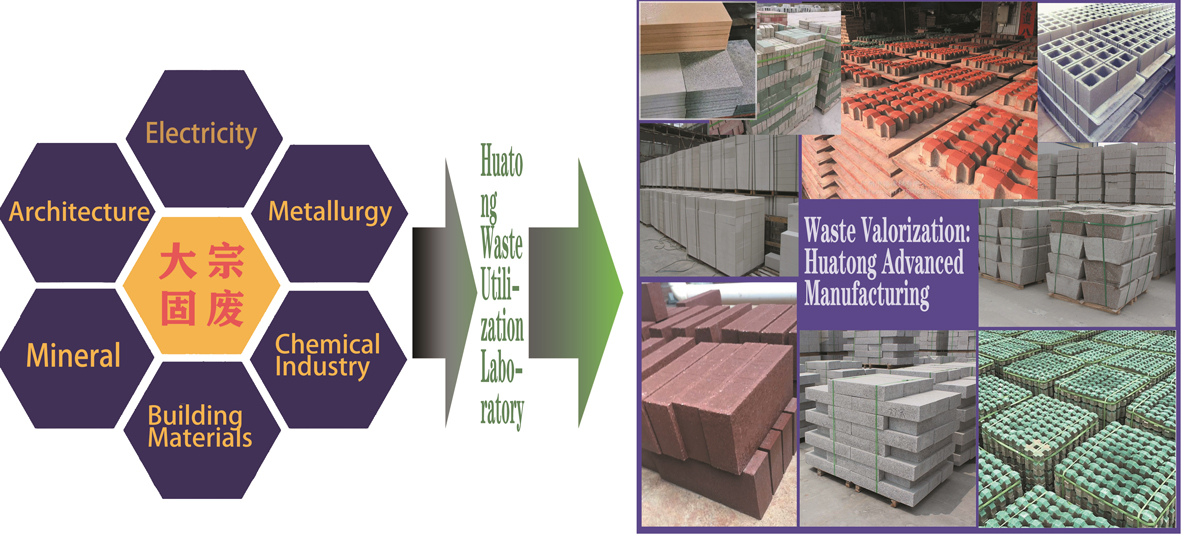

Shandong Huatong collaborates with multiple universities and research institutions to drive innovation, combining its in-house solid waste utilization laboratory technologies to achieve high-performance, CNC-based, automated, and intelligent large-scale industrial solid waste utilization capabilities.

The Huatong intelligent waste-utilization integrated green building materials production line adopts internationally advanced patented mixing technology, intelligent program control systems, and specialized curing agents for solid waste, achieving large-scale, high-quality production capacity.

Main Equipment:

Fully automatic crushing and sorting system, intelligent block molding production line, admixture spray atomization system, wireless automatic curing system, automatic brick-board separation system, automatic packaging system, and central control system.

The production line operates through an intelligent programmable control system, ensuring high production efficiency and stable product quality.

(IV) Project Case Studies

To date, Huatong’s intelligent integrated waste-utilization production lines have been applied in nearly 200 production facilities across 30 provinces and municipalities in China, covering the power, chemical, metallurgy, mining, and building materials industries, and exported to 53 countries across Asia, the Middle East, Africa, and the Americas.

Each year, Huatong’s customers collectively produce over 3 billion standard bricks, consume more than 10 million tons of solid waste, save 1,500 acres of farmland, and reduce standard coal consumption by 150,000 tons, generating significant economic and social benefits.

The system utilizes various waste materials — fly ash, coal gangue, tailings, slag, stone waste, construction debris, oil-contaminated soil, and industrial gypsum — to manufacture green building materials. Each production line consumes up to 100,000 tons of solid waste annually, producing dense, cost-effective products.

Case 1: 300,000 Tons/Year Iron Tailings Permeable Brick Production Line

Project Overview:

Located in a western mining city, this project extracts barite from iron tailings, then screens particles >2mm for use as aggregates and utilizes <2mm tailings mud to produce green static-pressed blocks.

Covering 33 acres, it includes three production lines:

1 million tons/year tailings aggregate production line,

1.5 million tons/year static-pressed green block line,

30,000 tons/year barite extraction line.

Highlights:

The project employs Huatong waste-utilization equipment with intelligent, automated, circular design, ensuring energy efficiency, low noise, dust-free, and wastewater-free operation.

The non-fired, non-steam green blocks are suitable for load-bearing walls, municipal pavements, sponge cities, and riverbank protection, realizing true “zero-waste” tailings utilization.

Significance:

Unlocks the key bottleneck in mining tailings utilization and forms a circular economy chain;

Revitalizes previously idle mining enterprises;

Creates a new industrial growth driver and supports regional economic inclusion.

Case 2: 500,000 Tons/Year Industrial Byproduct Gypsum Utilization Project

Investment: 17.5 million RMB | Area: 108 acres

Phase I:

Includes one fully automatic crushing and screening system, batching and mixing system, wheel-rolling mixing system, and a 250,000 t/yr green building materials block molding line.

Phase II:

Will add another 250,000 t/yr block line, wireless robot curing system, brick-board separation platform, and automatic wrapping systems.

Case 3: 100,000 Tons/Year Urban Solid Waste Utilization Line

Uses >70% urban solid waste to produce standard bricks, paving bricks, and hollow blocks, consuming 100,000 tons of waste per year and achieving significant environmental benefits.

Case 4: 200,000 Tons/Year Drilling Cuttings & Desulfurization Ash Project

Uses natural gas drilling cuttings and desulfurization ash to produce new eco-friendly materials.

Key equipment includes HT1100 hydraulic press, MPG1000 planetary mixer, 2000-type wheel mill mixer, PLC centralized batching control, and automatic palletizing & packaging systems, with an annual output of 300,000 tons of new materials and strong economic performance.

Case 5: Construction Waste Green Building Materials Project

Consumes 1.5 million tons/year of construction debris and soil waste, producing over 700 million standard bricks per year.

Products are cost-efficient, energy-saving, and environmentally friendly, achieving a perfect balance between economic and social benefits.

Case 6: 210,000 Tons/Year Coal Gangue Utilization Project

Investment: 12.6 million RMB | Area: 83 acres

Phase I:

Includes a coal gangue crushing system, two 100,000 t/yr batching systems, and two fully automatic block production lines.

Phase II:

Adds wireless robot curing systems, brick-board separation systems, and automatic wrapping machines.

The project builds a circular economy chain centered on coal gangue utilization, promoting regional industrial upgrading and sustainable growth.

(V) Huatong Waste-Utilization Laboratory

Huatong’s Solid Waste Utilization Laboratory collaborates with:

China Building Materials Academy

Shandong Institute of Building Materials Industry Design

University of Jinan

Dezhou College Fly Ash Research Institute

Shandong University

The lab provides comprehensive technical services by collecting and testing diverse solid waste materials from across China — including construction debris, shield tunneling mud, slag, sludge, steel slag, and mine tailings — to develop customized product formulations.

Equipped with a wide range of testing instruments (for compressive strength, flexural strength, freeze–thaw resistance, etc.), the lab ensures the reliability and performance of all products.

Looking forward, Shandong Huatong will continue to uphold and practice the principle that “lucid waters and lush mountains are invaluable assets”, intensifying R&D in solid waste recycling technologies and equipment.

We firmly believe that customer satisfaction is our driving force, and mutual success with our clients is the principle we will always uphold.