Cement Bricks Mixer

Model: MPG-2000 Cement Bricks Mixer

Brick mixers are equipment used in brick-making or construction projects. They are designed to mix various materials, such as cement, sand, water and additives, to form a homogeneous mixture. Brick mixers come in different sizes and capacities, ranging from portable mixers for small-scale construction projects to fixed mixers for large commercial projects.

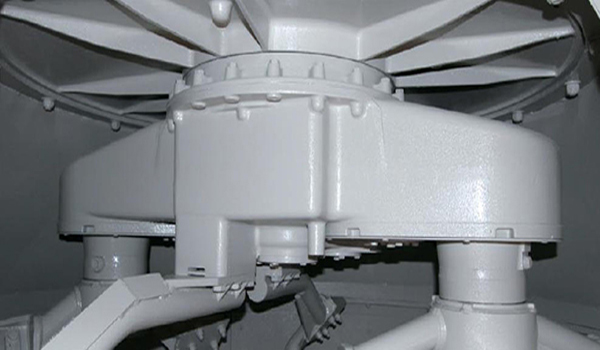

The vertical planetary mixer boasts high output and precision in mixing. Regardless of the equipment size, it guarantees consistent mixing performance across all units. Typically integrated into concrete mixing plants, this mixer offers versatile configurations—including multiple discharge gates—and supports simultaneous operation by multiple production lines.

Specification | MPG2000 |

Feeding Capacity (L) | 3000 |

Discharge Capacity (L) | 2000 |

Discharge Mass (KG) | 4800 |

Mixing Rated Power (KW) | 75 |

Hydraulic Discharge Power (KW) | 4 |

Number of Planets/Blades | 3/6 |

Side Scraper | 1 |

Discharge Scraper | 2 |

Mixer Weight (KG) | 8500 |

Hoist Power (KW) | 22 |

Overall Dimensions (L*W*H mm) | 3424*3217*2790 |

Product Advantages

The planetary mixer’s asymmetrical mixing arms eliminate dead zones during high-speed mixing in the drum, boosting efficiency | |

The transmission system adopts a high-performance Siemens motor and a custom reducer from a leading group. These premium components deliver strong load capacity, high output torque, low noise, and low energy consumption | |

During mixing, the arm rotates on its own axis while revolving around a center, creating complex intersecting trajectories to eliminate dead zones and inefficiencies. | |

Wear-resistant liners are constructed from either NM500 steel or high-chromium wear-resistant alloy cast iron (KMTBCr15Mo2-GT). Every cast iron component features a unique identifier, allowing maintenance staff to order replacement parts directly | |

The water atomizing nozzle adopts six diagonally spraying nozzles, enabling wide coverage and more uniform mixing humidity | |

The hydraulic pump station is independently R&D and designed. Its switch employs an engineering hydraulic cylinder equipped with a buffer device, guaranteeing smooth and reliable door opening and closing |

Company Qualifications

![Cement Bricks Mixer Cement Bricks Mixer]()

Shipping and Logistics

![Cement Bricks Mixer Cement Bricks Mixer]()