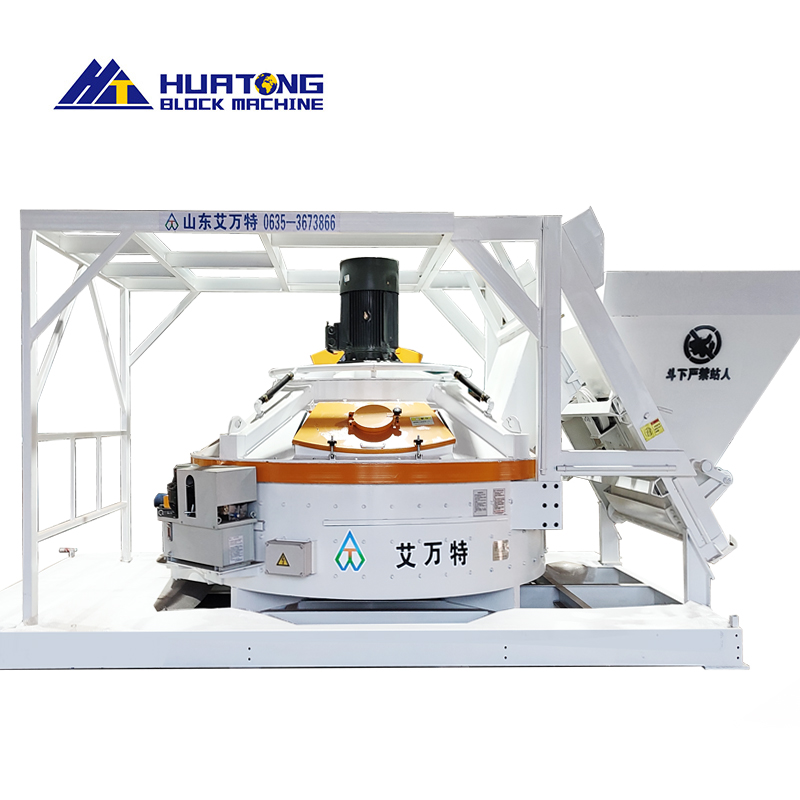

Planeary Brick Mixer

Advantages of MPG-2500 Vertical Planetary Brick Mixer

1. High-Efficiency Precision Mixing

The vertical shaft planetary mixer delivers exceptional production capacity with precise mixing homogeneity, ensuring consistent performance across all unit configurations. When integrated into concrete batching plants, it can be equipped with multiple discharge gates to simultaneously supply several production lines.

2. Reliable and Low-Maintenance Operation

Engineered for operational simplicity with minimal failure rates, the mixer maintains stable performance through its compact design. The leak-proof shaft construction significantly reduces operational disruptions, repair requirements, and long-term maintenance costs.

3. Advanced Mixing Technology

Utilizing genuine planetary gear-driven motion, the system ensures homogeneous blending without material degradation, segregation, or agglomeration, thereby fully preserving the original characteristics of all mixture components.

Technical Specifications of Vertical Planetary Mixer

1. High-Capacity Precision Mixing

The vertical planetary mixer delivers exceptional production output while maintaining precise mixing homogeneity, ensuring consistent performance across all equipment scales and configurations.

2. Flexible Plant Integration

Engineered for seamless integration into concrete batching plants, the system supports multi-door discharge configurations and simultaneous servicing of multiple production lines.

3. Operational Advantages

Guaranteed mixing consistency independent of unit capacity

Configurable material distribution systems

Parallel production line compatibility

Scalable output matching plant requirements

Specification | MPG2500 |

Feeding Capacity (L) | 3750 |

Discharge Capacity (L) | 2500 |

Discharge Mass (KG) | 6000 |

Mixing Rated Power (KW) | 90 |

Hydraulic Discharge Power (KW) | 4 |

Number of Planets/Blades | 3/6 |

Side Scraper | 1 |

Discharge Scraper | 2 |

Mixer Weight (KG) | 10500 |

Hoist Power (KW) | 22 |

Overall Dimensions (L*W*H mm) | 3690*3528*2790 |

Product Advantages

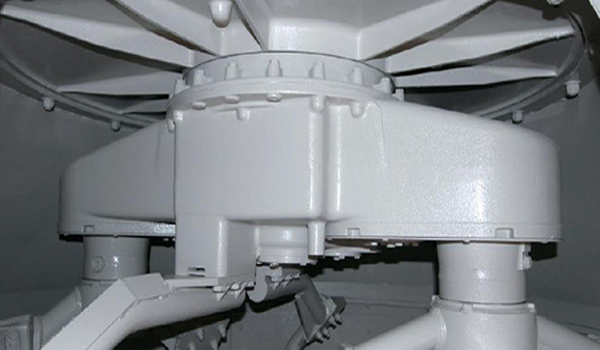

The mixing arms of the planetary mixer feature an asymmetrical structural design, which effectively eliminates the formation of dead zones during high-speed mixing operations within the drum. This structural characteristic significantly enhances overall mixing efficiency. | |

The transmission system is equipped with a high-performance Siemens motor, coupled with a custom-engineered reducer from a globally renowned industrial group. This premium configuration ensures exceptional load-bearing capacity while delivering significant operational advantages, including high output torque, reduced noise levels, and enhanced energy efficiency. | |

The mixing arm operates through a dual-motion mechanism involving simultaneous rotation about its own axis and revolution around the central axis. This compound kinematic pattern generates complex three-dimensional mixing trajectories, ensuring complete elimination of dead zones and achieving optimal homogenization throughout the mixing vessel | |

The wear-resistant liners are manufactured from premium-grade NM500 steel or high-chromium wear-resistant alloy cast iron (KMTBCr15Mo2-GT). Each cast component bears a unique identification marking, enabling maintenance personnel to accurately reference and procure replacement parts through direct ordering channels. | |

The water atomization system employs a hexagonal nozzle array configured for diagonal spray patterns, ensuring comprehensive coverage and optimized humidity distribution throughout the mixing chamber | |

The hydraulic pump station is independently developed and engineered. The switching mechanism employs an industrial-grade hydraulic cylinder integrated with a buffering system, guaranteeing exceptional smoothness and reliability during door operations |

Company Qualifications

![Planeary Brick Mixer Planeary Brick Mixer]()

Shipping and Logistics

![Planeary Brick Mixer Planeary Brick Mixer]()