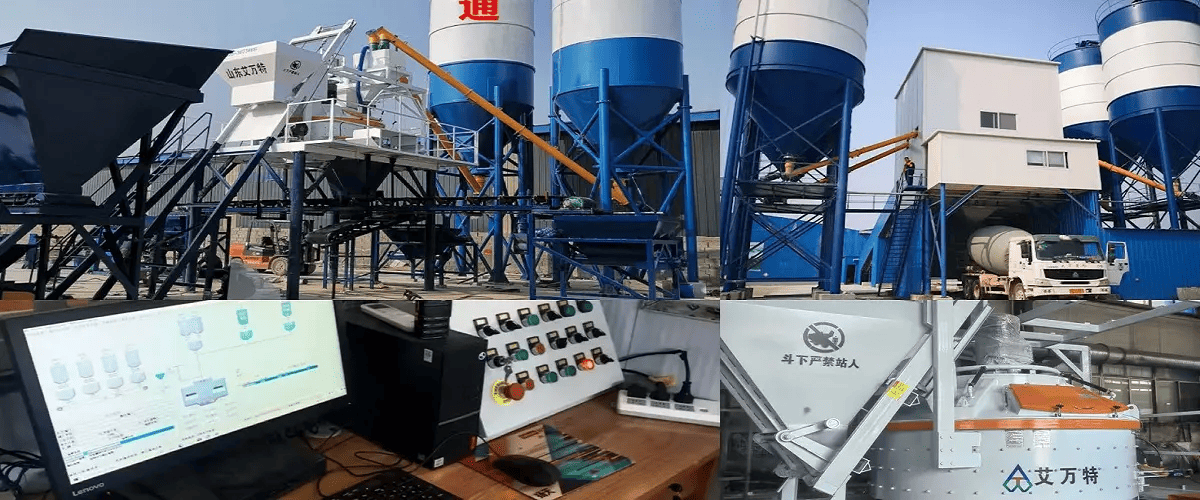

Concrete Batching Plants

Model:The HZN120 Engineering Concrete Batching Plants

Adaptive Application Range

Engineered to support medium-scale construction projects and commercial concrete production, with proven efficacy in critical infrastructure including hydropower facilities, transportation networks, aviation hubs, structural engineering, and prefabricated component manufacturing

Configurable Solutions

Multiple design configurations and installation schemes are available to align with specific operational requirements and site conditions

Concrete Mixing Plant Introduction

Technical Advantages of Vertical Planetary Mixing System

1. Precision Mixing Performance

The multi-axis planetary motion mechanism ensures homogeneous material distribution, effectively preventing concrete segregation. Demonstrates exceptional efficiency in processing dry-hard and high-performance concrete, with shortened mixing cycles yielding elevated output and guaranteed product consistency.

2. Compact Engineering Design

Space-optimized structure requires 30% less footprint than conventional batching plants, ideal for constrained worksites. Modular component design extends service life while minimizing long-term maintenance expenditure.

3. Versatile Production Capabilities

Engineered for specialized applications including bridge/tunnel concrete, precast components, and dry-mix mortar production. Compatible with cement products manufacturing and prefabricated construction requirements.

4. Intelligent Operation Efficiency

Optimized drive system reduces energy consumption by 15-20%. Automated controls enable precise parameter management, achieving operational economy through reduced labor input and component replacement costs.

5. Automated Cleaning System

Select models feature reversible drum rotation or motorized scrapers that prevent material buildup, eliminating manual cleaning requirements and maintaining consistent mixing quality across production cycles.

6. Aggregate Adaptability

Robust mixing mechanism accommodates varied particle size distributions and complex gradations, maintaining operational stability when processing mixed aggregates (crushed stone/pebble combinations) without blocking or segregation risks.

7. Rapid Deployment Configuration

Pre-assembled modular components reduce field installation duration by 30% versus traditional plants, supporting urgent project timelines through streamlined commissioning processes.

Mixing plant model | HZN120 |

Host model | MPG2000 |

Batching machine model | PLD3200 |

Theoretical production efficiency (m³/h) | 120 |