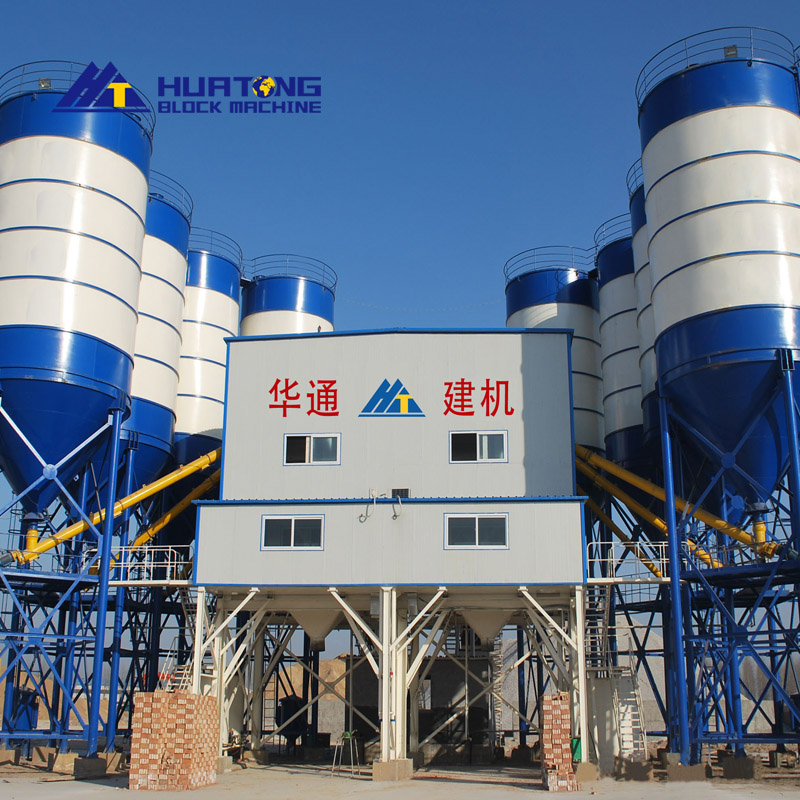

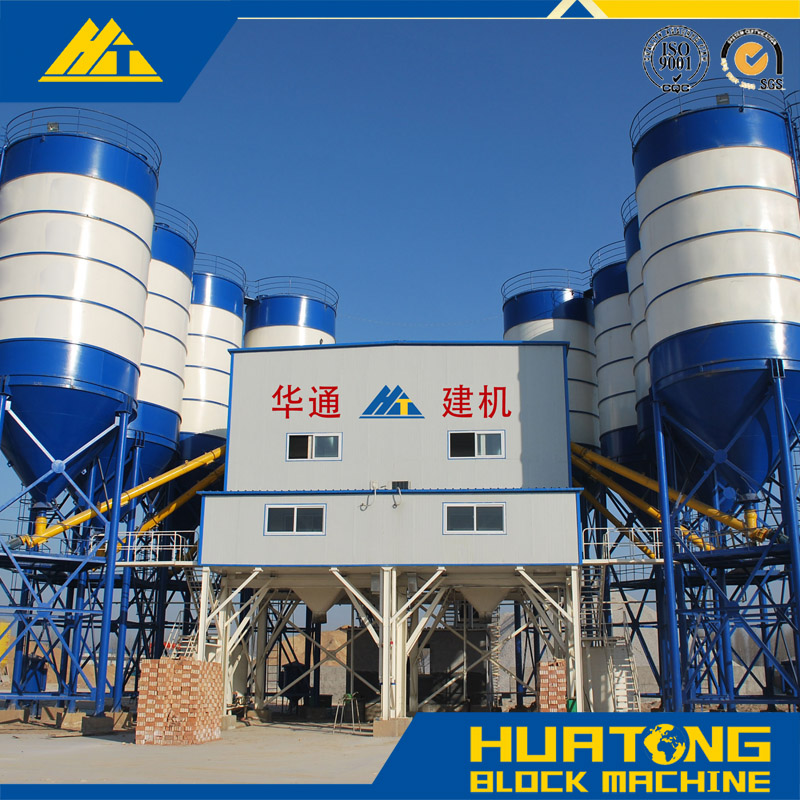

Batching Plant

Moder: HZN180

Engineering Concrete Batching Plant

A compact, automated production system with low investment costs and modular mobility.

Key Features

Supports infrastructure projects and commercial concrete production

Planetary mixer ensures fast, uniform mixing with intelligent control

Customizable configurations available

Applications

Hydropower/Bridge/Highway construction

Precast component manufacturing

Building and infrastructure projects

Concrete Batching Plant Technical Overview

System Configuration

This batching plant integrates an MPG1000 vertical planetary mixer as its core component, paired with a PLD1600 precision batching system. The configuration is specifically engineered for infrastructure projects requiring sustained concrete production at geographically concentrated sites, including hydropower developments, energy facilities, and bridge construction.

Technical Features

Self-cleaning mixer mechanism preventing material adhesion

Wear-resistant hopper with 5x service life enhancement

Leak-proof additive dosing system

Pressurized water metering for precise slump control

Modular automated design enabling rapid commissioning

Non-stick sand hopper with enclosed eco-friendly loading

Centralized dust collection with pulse-jet filtration

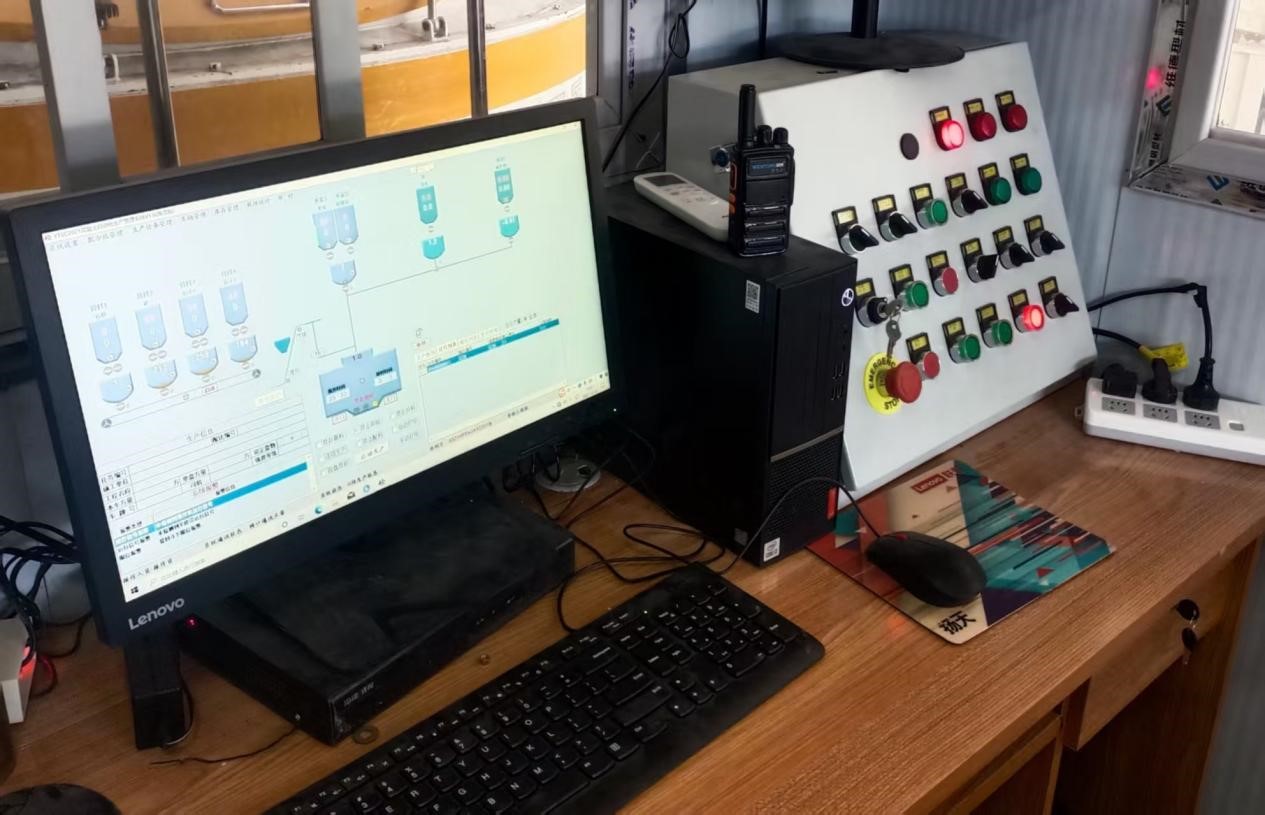

Intelligent control system with auto-correction and diagnostics

Plant Architecture

The Avant station comprises four integrated subsystems:

Vertical planetary mixing unit

Structural platform

Material handling system (belt/bucket options)

Automated control center

2. Batching machine: two types: cumulative metering and separate metering

3. Metering system: including water metering, cement metering, and admixture metering

4. Control system: divided into two types: full computer automatic control and touch screen automatic control

Mixing plant model | HZN180 |

Host model | MPG3000 |

Batching machine model | PLD4800 |

Theoretical production efficiency (m³/h) | 180 |