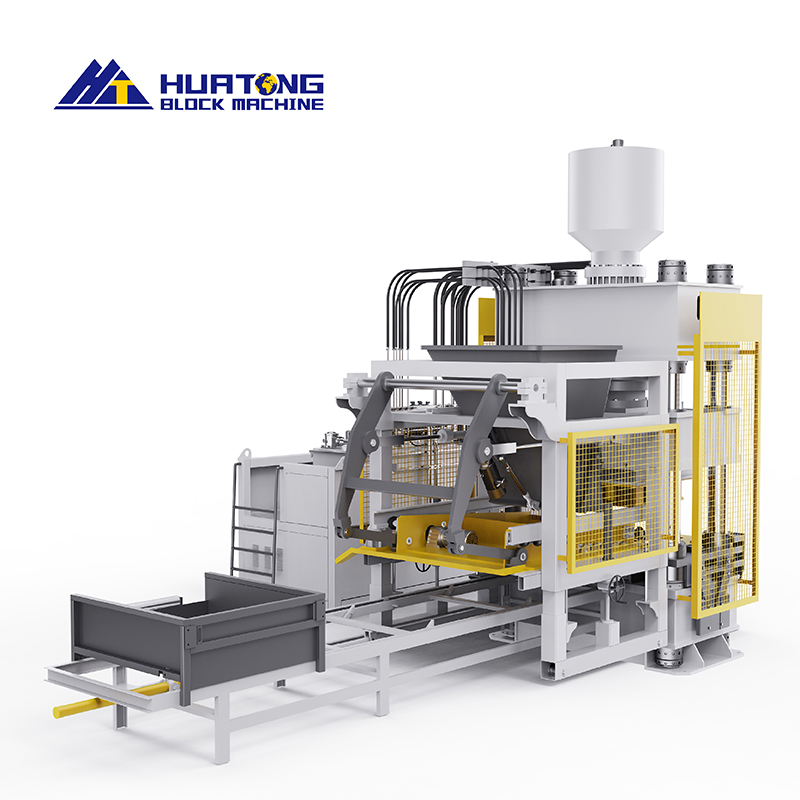

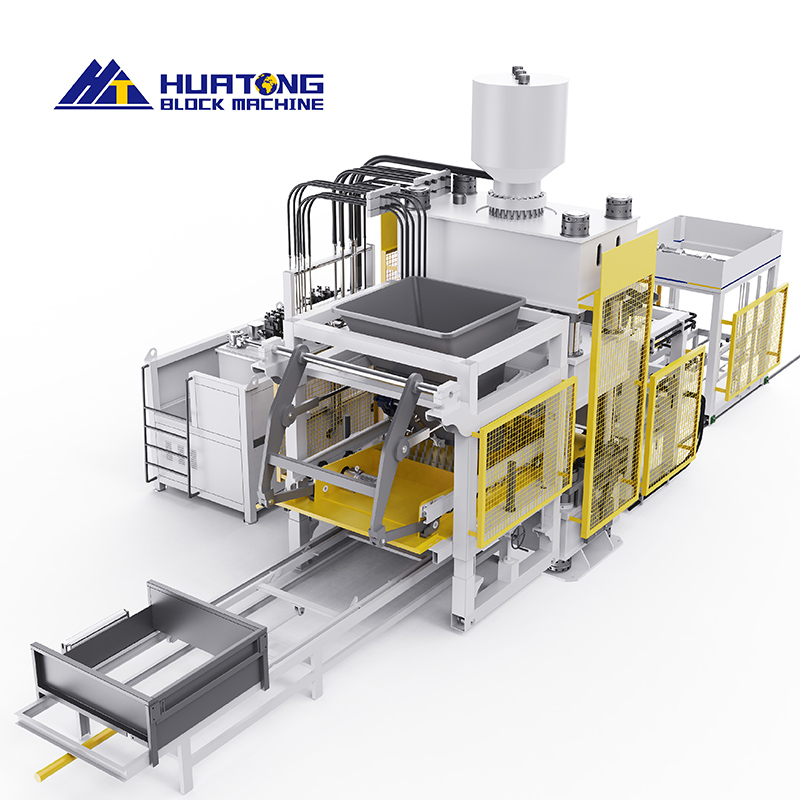

Automatic Hydraulic Press Brick Machine

Robust & Durable: Critical structural components are reinforced and upgraded, ensuring long-term stable operation under high-pressure and high-frequency working conditions.

Intelligent & Efficient: Equipped with an intelligent closed-loop hydraulic and vibration system capable of adaptive parameter adjustment. Supports predictive maintenance and remote diagnostics to maximize efficiency and minimize downtime.

The HT800 Fully Automatic Hydraulic Block Forming Machine is an innovative brick-making system that combines the strengths of high-tonnage static pressure technology and traditional vibration compaction molding processes. Adopting exclusive composite pressing technology, it addresses the technical bottlenecks of inadequate density and poor noise control in medium-density material molding—realizing quiet, efficient operation with a noise level of ≤75 dB. Its electro-hydraulic integrated system is equipped with world-renowned hydraulic power units and intelligent control systems, offering stepless speed adjustment, real-time fault diagnosis, and remote maintenance functions. It also supports system upgrades and production monitoring through a cloud-based platform.By replacing molds, the equipment allows for quick production switching between paving blocks, standard bricks, and other diversified products. When paired with specialized soil stabilizers, it can efficiently process industrial solid wastes like tailings sand and shield tunneling muck—boosting solidification efficiency by 40% and enabling waste material incorporation rates of over 50%. Boasting notable advantages such as a 60% reduction in investment costs and 35% lower operating expenses, it has emerged as an ideal solution for small and medium-sized enterprises striving for environmental transformation and resource utilization. This system has been successfully applied in more than twenty solid waste treatment projects, attaining a customer satisfaction rate of 98.2%.

Technical Parameter:

HT800 Model Technical Parameter | |

Production Cycle | 15-20s |

Maximum Pressure | 8000KN |

Power of Main Machine | 55kw |

Pressure | 31.5MPA |

Dimension | 8850x4000x4750mm |

Pallet Size | 1150x950x25mm |

Weight | 23000KGS |

Vibration Motor | 2x7.5kw |

Post Size | Ø180mm |

Production Capacity:

Product Type | Image | Size(mm) | Per Molding | Cycle Time | Daily Output (10 hrs) |

Standard Brick | 238x114x50mm | 48pcs | 15-20s | 85400-115200 | |

Paving Block | 200x100x60mm | 35pcs | 15-20s | 63000-84000 | |

Paving Block | 230x115x60mm | 24pcs | 15-20s | 43200-57600 |

Product Details

| Composite Structure of Rapid Cylinder: Adopts the "small oil cylinder embedded in large oil cylinder" design. During operation, high-pressure oil is first injected into the small oil cylinder. Taking advantage of the characteristic that the effective area of the small oil cylinder is smaller than that of the large oil cylinder, it drives the large oil cylinder to extend rapidly, realizing long-stroke and fast pushing, and significantly improving production efficiency. |

Top Oil Storage Bag Design: An oil storage bag is installed on the top of the large oil cylinder. Only a small flow of high-pressure oil provided by the hydraulic system is needed to meet the working requirements. This design has low energy consumption, which can directly reduce production costs; at the same time, it can prevent the hydraulic oil in the oil cylinder from heating up, effectively prolonging the service life of the oil cylinder. |  |

| 360°Rotating Material Distribution System: Equipped with a material distribution box conveying device, it realizes 360° dead-angle-free rotating material distribution, making the material distribution more uniform and faster, and ensuring the consistency of brick billet forming. |

Bionic Crank Arm Type Double-Cylinder Material Distribution: Adopts a bionic crank arm structure combined with double-cylinder drive. It not only improves the material distribution speed, but also enhances the operation stability of the material cart, and greatly reduces the equipment failure rate. |  |

| Patented Full-Process Auxiliary Vibration Technology: It is a patented design of Huatong Company. With the help of auxiliary vibration during the entire working cycle of the equipment, it can not only realize fast material distribution, but also increase the density of finished products and enhance the quality of brick billets. |

Split-Type Machine Body Structure: The equipment is designed to be detachable. When replacing molds or cleaning the internal part of the equipment, the machine body can be directly pulled apart for operation, making maintenance and cleaning more convenient and efficient. |  |

| Adjustable Track Wheels for Material Distribution Box: The track wheels support fine adjustment, which can optimize the operation stability of the material distribution box, accurately control the operation gap, and fundamentally avoid the problem of material scattering. |

Balance Gear Mold Stabilization Design: Through the balance gear structure, it improves the stability of the mold during movement, ensures more standard dimensions of finished products, and reduces specification errors. |  |

| Dual-Pump Intelligent Hydraulic System: Adopts a dual-pump parallel working mode, which can automatically adjust the oil supply method according to the actual working conditions. It outputs large flow during rapid movement and provides high pressure under high load. It not only improves the system response speed and work efficiency, but also reduces energy consumption, adapting to diversified production needs. |

Packing and Loding:

Our Company:

Shandong Huatong Hydraulic Machinery Co., Ltd. (referred to as "Shandong Huatong"), established in 2004 and headquartered in Gaotang County, Shandong Province, is a technology-driven enterprise specializing in the design, R&D, manufacturing, and sales of comprehensive utilization equipment for bulk industrial solid waste.

The company's product portfolio includes intelligent production lines for automatic block forming machines, automatic static pressure forming systems, high-precision assembled gypsum block production lines, aerated concrete block production lines, and vertical shaft planetary mixing stations. Additionally, it offers customized waste solution design, preparation, and operational services.

Through its subsidiary companies—Huatong Machinery, Avante Machinery, Darun Environmental Protection, and Cote d'Ivoire Shandong Group Company—Shandong Huatong leverages the expertise of over 270 engineers and technical professionals across various disciplines. This robust workforce supports the company's commitment to innovation and sustainable industrial solutions.