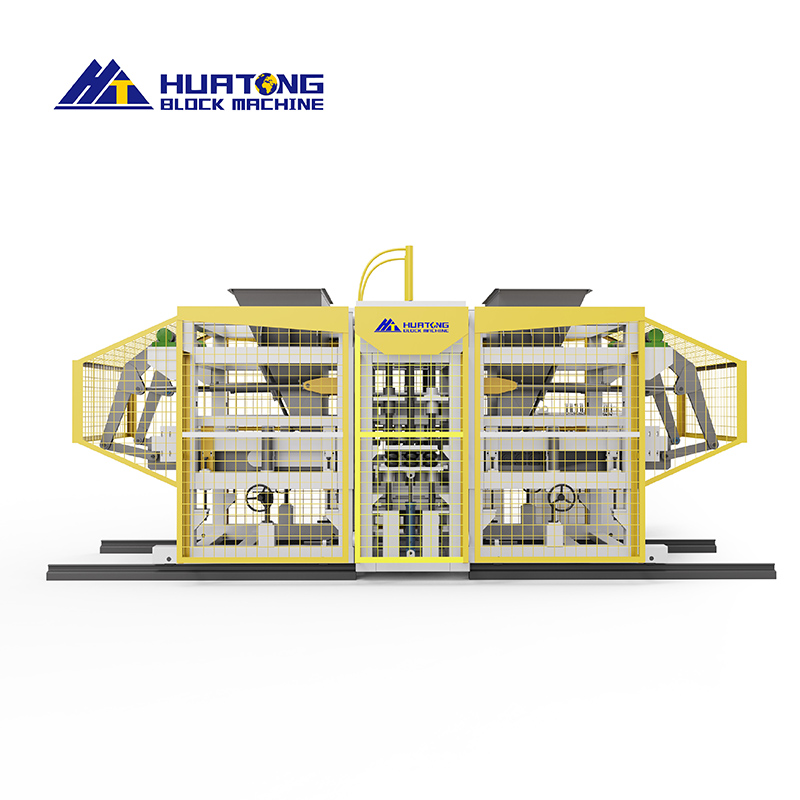

Moulding Block Machine

The Moulding Block Machine structure is stable: the body adopts thick-walled square tube and super-long guide sleeve, with extremely low center of gravity, ensuring that 90% of aftershocks are introduced into the ground, with remarkable shock absorption effect and prolonging the service life of the equipment.

Superior performance: the moulding block machine vibration and pressure separation technology can completely isolate the interference of the resistance vibration and pressure, and the exciting force is strong.

Moulding Block Machine is a fully automatic fixed multi-layer production equipment, an outstanding representative of construction bricks and similar products production equipment, with high performance, high output, high quality and high cost performance. Germany advanced technology, moulding block machine adopts a number of latest technologies such as visual menu navigation, and has the characteristics of simple operation and low maintenance and repair costs.

Technical Parameters of QT15-15 Moulding Block Machine:

| Dimension | 4170*2650*3260mm |

| Mode of Vibration | Table Vibration |

| Pallet Size | 1350*1150*25-40mm |

| Rated Pressure | 21Mpa |

| Oil Station Power | 22KW |

| Cycle Time | 15-20'S |

| Mould Rockwell Hardness(HRC) | ≥55 |

| Application Category | Construction industry: production of concrete hollow blocks, solid bricks, etc. |

| Raw Material | Cement, sand and gravel, stone powder, stone nitrate, slag, slag and other building materials |

Production Capacity of QT15-15 Moulding Block Machine:

| Block Type | Picture | Size(L x W x H) | Pcs./Pallet | Cycle Time | Pcs./8 Hours |

| Hollow Block |  | 400x200x200mm | 15 | 15-20's | 21600-28800 |

| Hollow Block |  | 400x150x200mm | 18 | 15-20's | 25900-34500 |

| Hollow Block |  | 400x100x200mm | 24 | 15-20's | 34500-46000 |

| Paving Block | 200x100x60mm | 54 | 20-25's | 62200-77700 | |

| Paving Block |  | 225x112.5x60mm | 35 | 20-25's | 40300-50400 |

Product advantages of Moulding Block Machine:

1,Bionic crank arm type parallel bars cloth, improve the cloth speed and stability, reduce the failure rate.

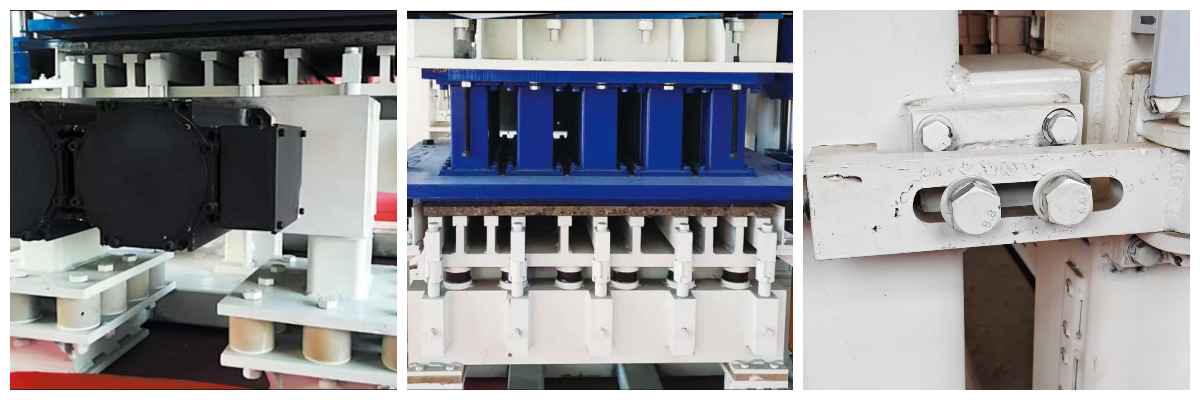

2,The design of six guide columns and ultra-long guide sleeves increases the stability of equipment movement and the finished product size is more standard.

3,The hand-crank lifting device is more convenient and quick when changing the mold to adjust the height of the cloth machine.

4,The direct-connected transmission mode of the servo motor can overcome the problem of ordinary motor out-of-step, realize the closed-loop control of position, speed and torque, and has strong anti-overload ability, especially suitable for equipment with instantaneous load fluctuation and quick start.

5,The dynamic and static vibration platform reduces the load when the vibration motor tells the operation, and the concrete is fully liquefied and exhausted instantly, and the size of the finished product is more standard.

6,The detachable assembly design makes it easier to replace the mold and clean the inside of the equipment.

Moulding Block Machine is the 1 kind of mechanical equipment that completes the whole process of raw material mixing, pressing molding, automatic demoulding, conveying and maintenance through an automatic system to realize efficient and standardized production of bricks. The core advantage is to greatly reduce manual intervention and improve production efficiency.

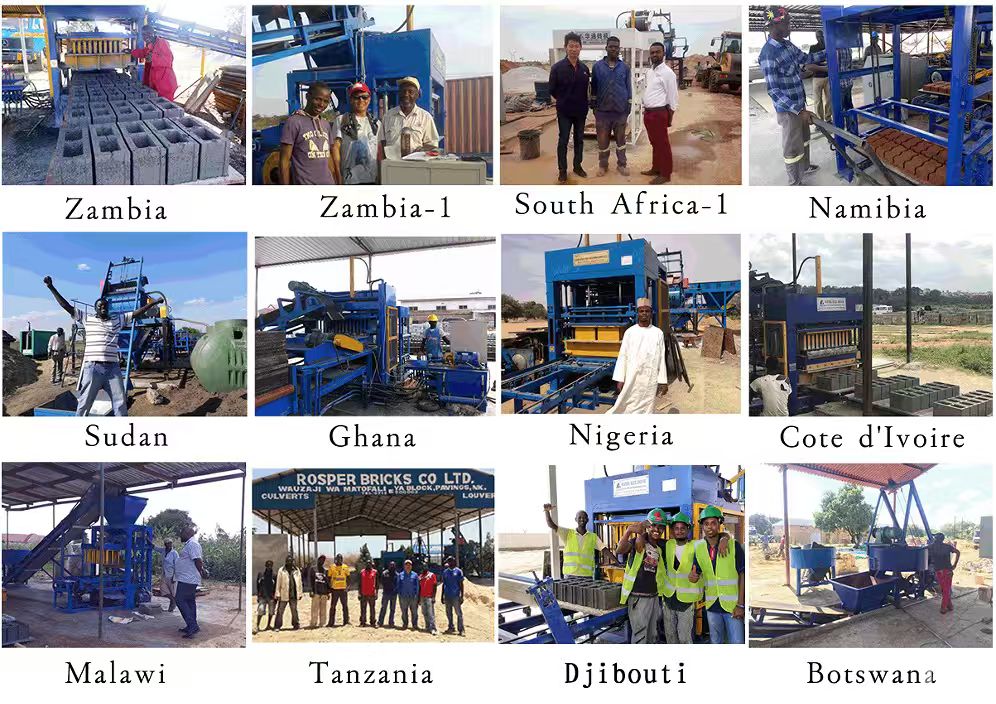

Part of Moulding Block Machine Customer Work Site:

We had many customers over the world,such as Pakistan,Kazakhstan,South Africa,Botswana,Tanzania,Kenya,

Zambia,Malawi,Ghana,Namibia,Tanga,DR Congo,Benin.

Some of our Clients work site:

Best Service:

Pre-sale service:

1. Accept customer inquiries, introduce our company's status and product categories.Guide customers in selecting suitable products based on local market demand.

2. Determine the scale of operations and guide customers in selecting equipment based on required production volume and investment budget.

3. Explain the production process, answer questions, and design a factory construction plan for customers.

4. Provide factory construction drawings, participate in construction supervision, and develop a feasible investment plan based on actual conditions.

During sale service:

1. Review the contract, confirm or amend any unclear points or issues requiring negotiation.Track equipment production progress in real time to ensure on-time delivery.

2. Issue production instructions and schedule production as required.

3. Provide plant layout plans and equipment foundation drawings in advance. If necessary, arrange on-site guidance on infrastructure, water, and electricity.

4. Provide technical consultation, assist in establishing a management framework and train production management personnel.

5. Arrange technicians to provide on-site installation guidance and train production operators.Establish processes, and subcontract responsibilities. From quality control and cost control, employee assessments to subcontracting, safety production, equipment maintenance, procurement, and marketing, we aim to help customers enter the industry quickly and achieve profitability.

After Sale Service:

1. We establish customer profile which documents model, configuration, and special requirements.It allowe us to provide the services they need more accurately and promptly.

2. We offer telephone support. After confirming your service request, Huatong after sales technicians will assist you by phone in locating the fault and proposing a solution.