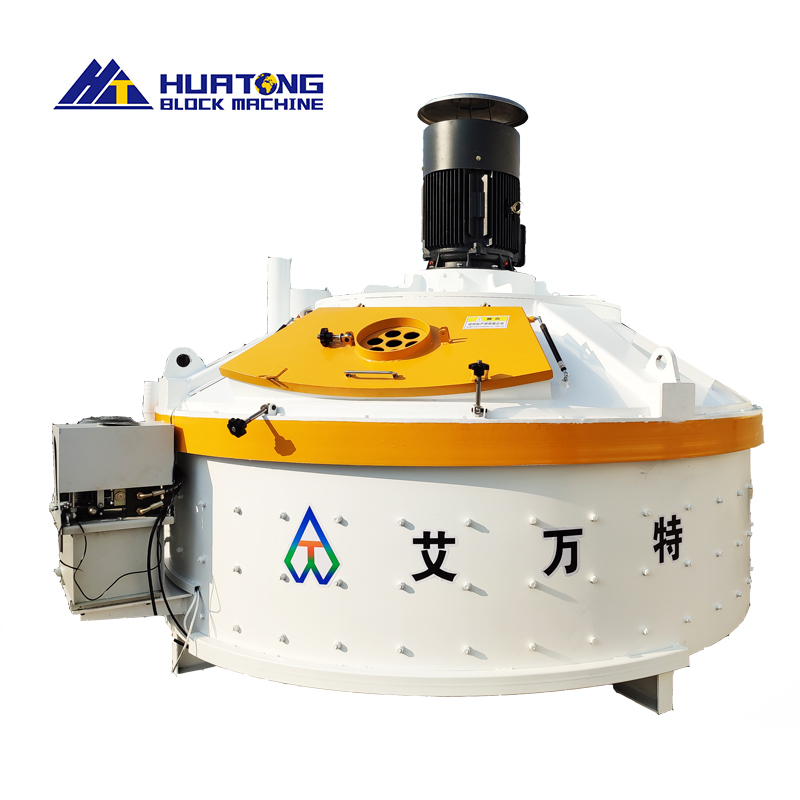

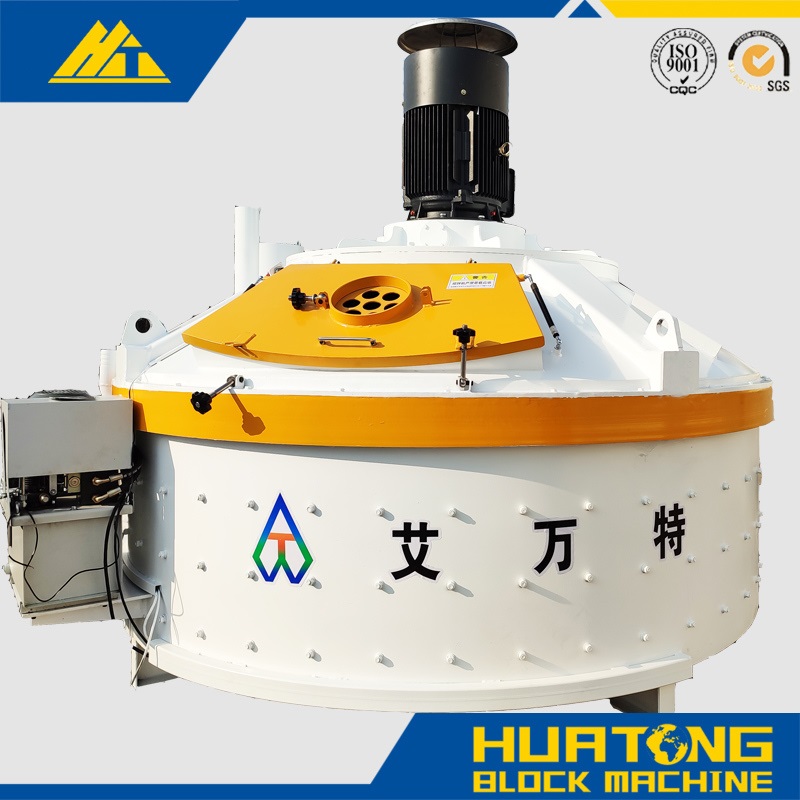

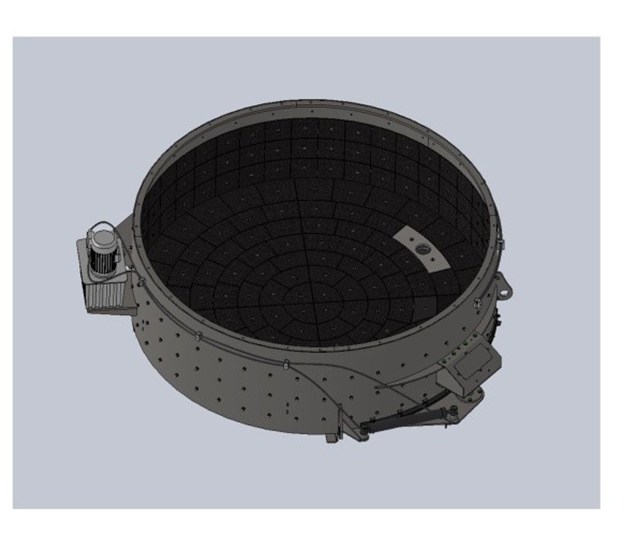

Vertical shaft concrete mixer

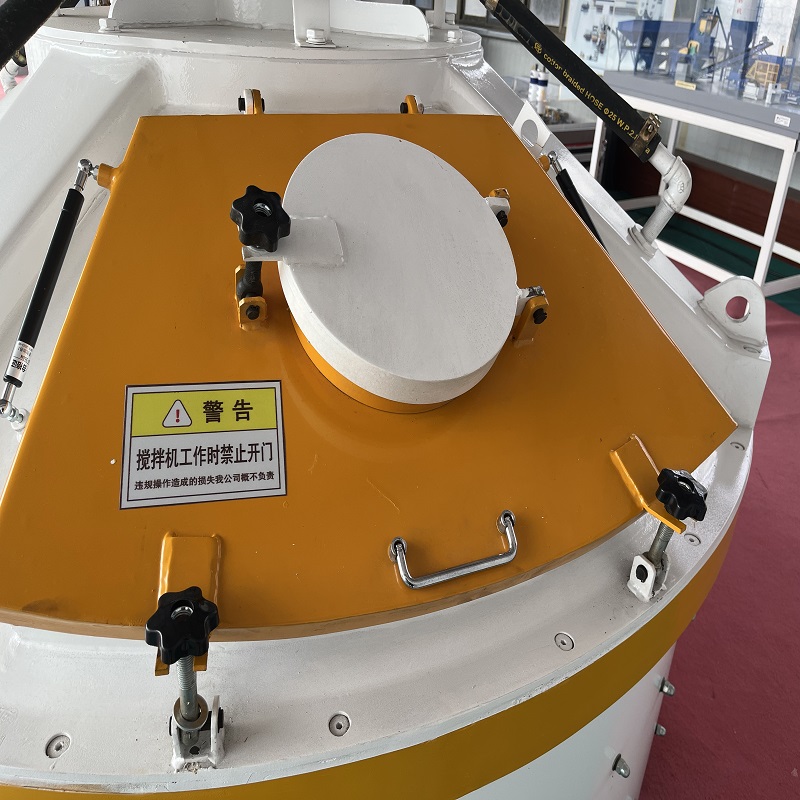

The Vertical shaft concrete mixer boasts exceptional design rationality and operational stability, simplifying routine maintenance and effectively reducing maintenance costs. Its powerful powertrain ensures the integrity of materials while precisely completing mixing operations and guaranteeing high-quality mixing. This equipment utilizes highly automated control to adapt to the mixing needs of a wide variety of materials. It is currently widely used in a variety of industries, including brickmaking, prefabricated component production, refractory processing, metallurgy, and glass manufacturing.

MPG500Advantages of Vertical Shaft Mixers:

Operational Efficiency:

Automated and Efficient:

Reducing manual intervention and improving production efficiency.

High Degree of Automation:

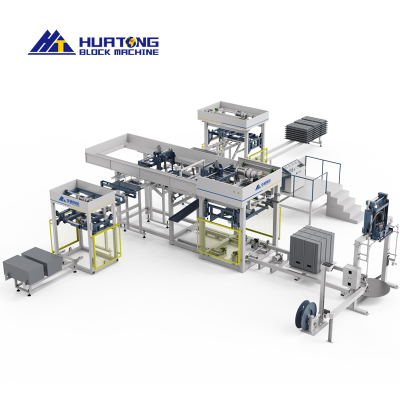

It can be integrated with the loading, metering, and unloading systems to achieve a fully automated mixing process, reducing manual errors and lowering labor costs.

Powerful and Efficient:

The high-power drive system quickly completes material mixing, shortening the mixing cycle. This significantly improves overall production efficiency, especially in large-scale production scenarios.

| Specification Item | Model: MPG500 | |||

| Feeding Capacity (L) | 750 | |||

| Discharge Capacity (L) | 500 | |||

| Discharge Mass (KG) | 1200 | |||

| Mixing Rated Power (KW) | 18.5 | |||

| Hydraulic Discharge Power (KW) | -- | |||

| Number of Planets/Blades | 1/2 | |||

| Side Scraper | 1 | |||

| Discharge Scraper | 1 | |||

| Mixer Weight (KG) | 2400 | |||

| Hoist Power (KW) | 5.5 | |||

| Overall Dimensions (LWH mm) | 2230*2080*1880 | |||

|  |

|

|

|  |

|

|

Equipment application scenarios

Shipping and Logistics

From outbound inspection to loading and securing, every step is strictly controlled to ensure that the equipment/cargo arrives intact. Subsequent logistics information will be synchronized immediately. If you have any questions, please feel free to contact us. We will escort you from beginning to end!