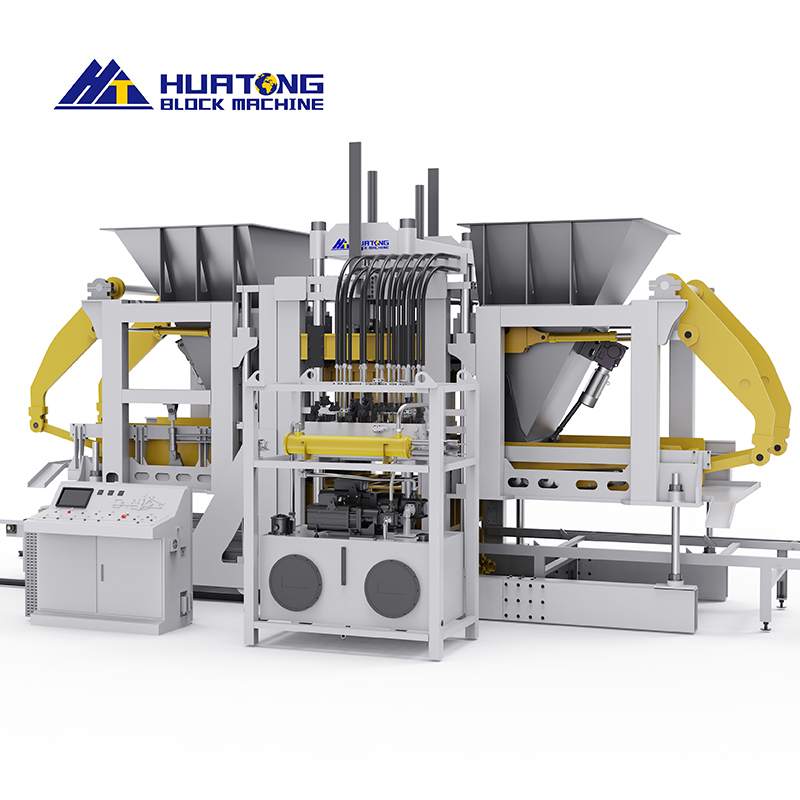

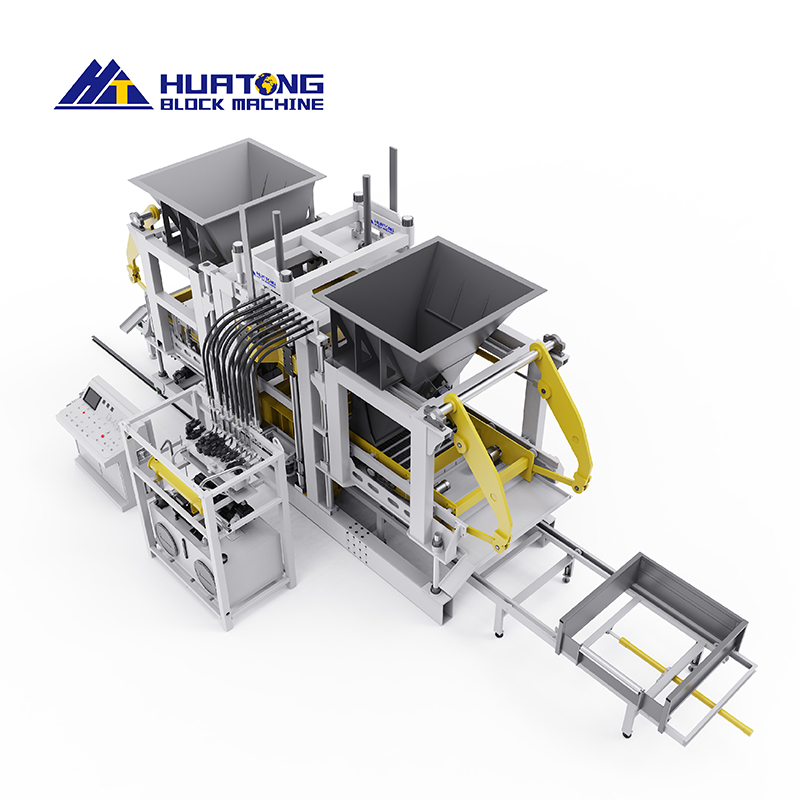

Automatic Blocks Making Machine

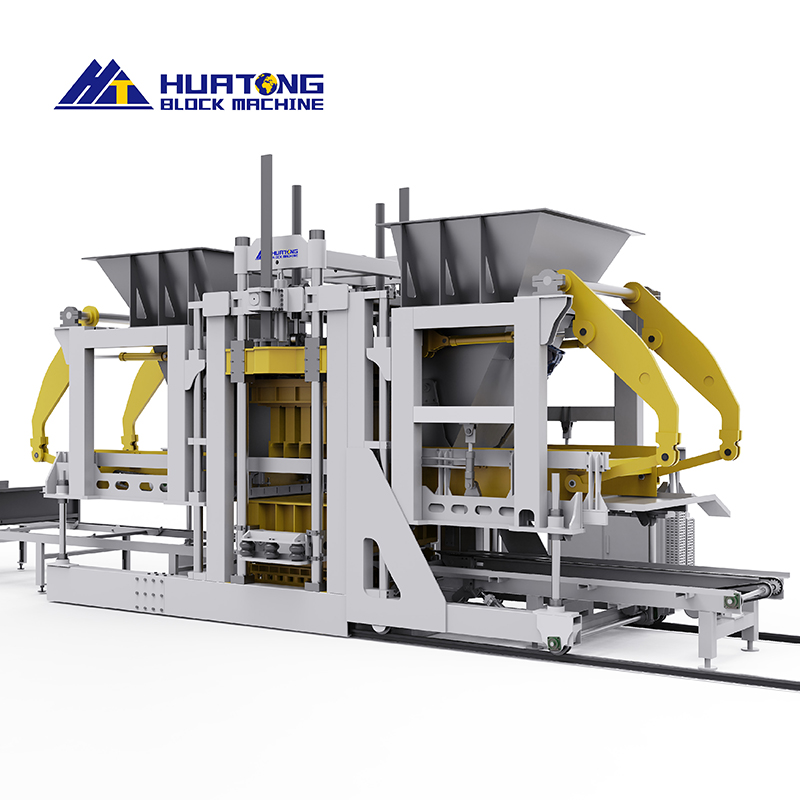

1. QT18-15 Automatic Blocks Making Machine mold adopts various heat treatment processes such as quenching, tempering, carburizing, etc., thereby improving the life of the mold.

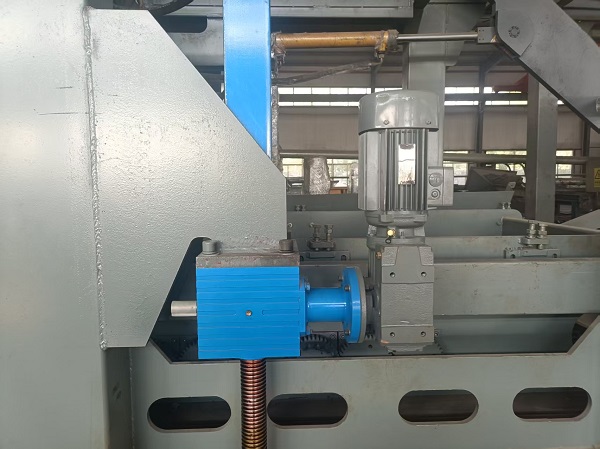

2. The hydraulic control system adopts imported high dynamic proportional valve.

3. Vibration system: Adopt German frequency conversion technology, host frequency conversion control, and the exciter assembly adopts oil-immersed type, which improves the load of high-speed operation.

4, The automatic blocks making machine system is stable and safe.

QT18-15 Automatic Blocks Making Machine is one equipment designed, developed, processed and manufactured by Shandong Huatong Company in fully absorbing foreign advanced technology. The automatic blocks making machine all key electronic control components, motor reducers, hydraulic and pneumatic components are all famous foreign brand products, so as to ensure the high reliability of equipment operation. The automatic blocks making machine is more user-friendly in terms of appearance design, structural design, and convenient operation. The performance of the automatic blocks making machine has reached the level of similar products in the world, and it is a general-purpose machine for processing concrete products with excellent performance.

Automatic blocks making machine Product Parameters:

Dimension | 5000*2800*4500mm |

Mode of Vibration | Table Vibration |

Pallet Size | 1400*1400*30-40mm |

Rated Pressure | 21Mpa |

Oil Station Power | 22KW |

Cycle Time | 15-20'S |

Mould Rockwell Hardness(HRC) | ≥55 |

| Application Category | Construction industry: production of concrete hollow blocks, solid bricks, etc. |

| Raw Material | Cement, sand and gravel, stone powder, stone nitrate, slag, slag and other building materials |

Capacity of Automatic Blocks Making Machine:

| Block Type | Picture | Size(L x W x H) | Pcs./Pallet | Cycle Time | Pcs./8 Hours |

| Hollow Block |  | 400x200x200mm | 18 | 15-20's | 25900-34500 |

| Hollow Block |  | 400x150x200mm | 24 | 15-20's | 34500-46000 |

| Hollow Block |  | 400x100x200mm | 33 | 15-20's | 47500-63300 |

| Paving Block |  | 200x100x60mm | 66 | 20-25's | 76000-95000 |

| Paving Block |  | 225x112.5x60mm | 45 | 20-25's | 51800-64800 |

QT18-15 automatic blocks making machine block sample,the machine can produce different Blocks by Changing Moulds,Such as Solid Blocks,Hollow Blocks,Paving Blocks,Interlocking Blocks,Kerbstone and so on.Block size follow customer requirement:

Performance characteristics of Automatic Blocks Making Machine :

Variable frequency vibration: The vibration platform is equipped with a variable frequency motor as the power system. Its advantage is that it starts instantly. The starting time is measured in milliseconds, and it can be quickly, slowly and stopped according to instructions. It not only shortens the molding cycle, but also greatly saves electricity. | |

Automatic blocks making machine use split design, hydraulic locking mode, more convenient to use, the body is more stable. | |

Automatic blocks making machine use automatic lifting mode: The lifting of the cloth box adopts the automatic lifting mode of the motor, which is more convenient to adjust the height of the cloth box when changing the mold, which is convenient, labor-saving and high efficiency. | |

Airbag mold clamping system: airbag type mold clamping, uniform and adaptive mold clamping force, high mold fitting accuracy, reducing finished product corners and cracks; buffer shock absorption, protect the mold and host, and extend the service life; simple structure and easy maintenance, The mold change efficiency is high. |

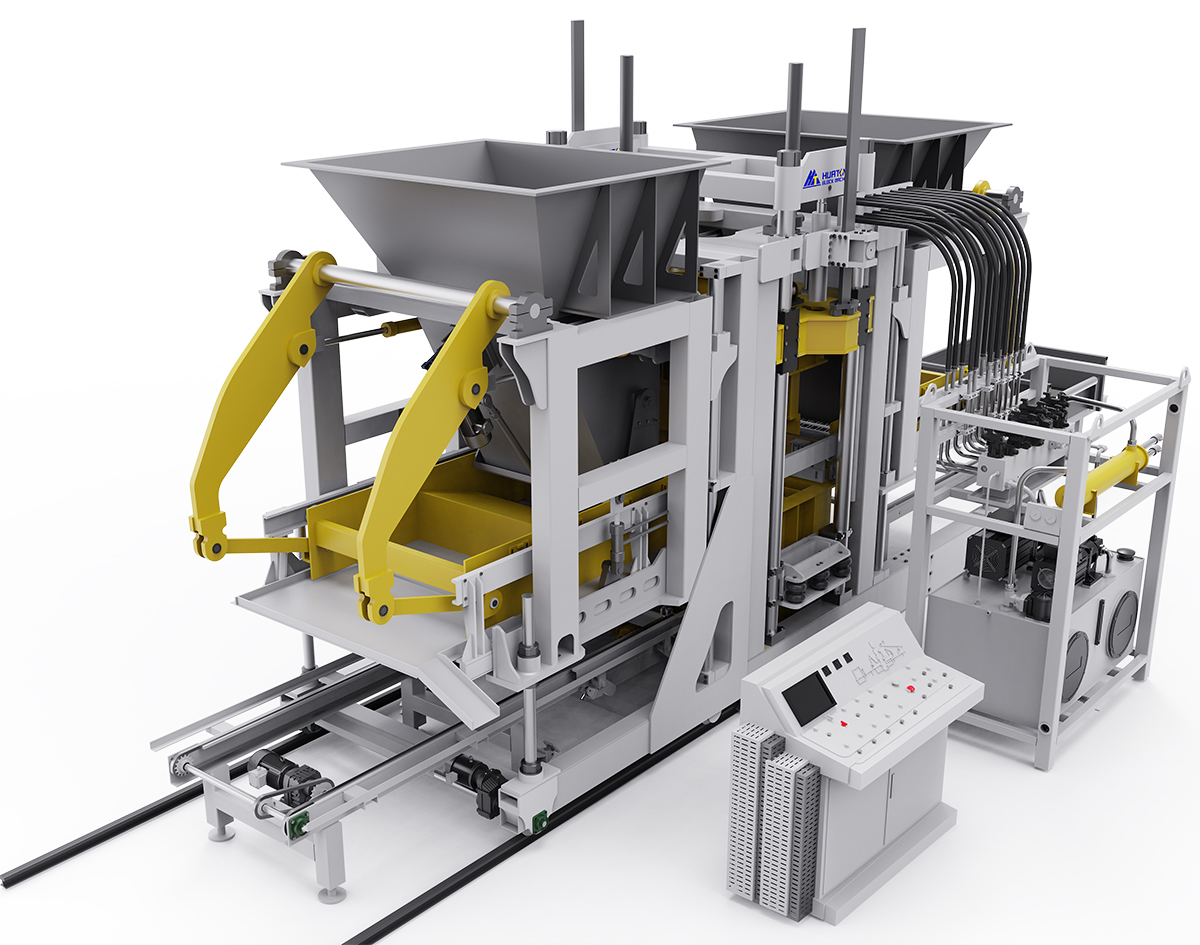

Servo hydraulic system:

1. Energy saving: The servo drive hydraulic system can save electricity by 20%-40%.

2. Low noise: The noise of the servo drive hydraulic system is generally less than 70dB, while the noise of the traditional hydraulic system is 83dB-90dB.

3. Less heat: The hydraulic oil consumed by the servo drive hydraulic system is generally only about 70% of that of the traditional hydraulic system.

4. High control accuracy: The pressure, speed and position of the servo hydraulic system are fully closed-loop digital control, and the pressure sensor measures the pressure of the system with a high degree of automation.

5. Convenient maintenance: The proportional servo hydraulic valve speed regulation circuit is canceled, and the hydraulic system is greatly simplified.

The enterprise has passed GB/T9001-2016/ISO9001-2015 quality management system certification, two integration management system evaluation certificate.

Packing And Loading of Automatic Blocks Making Machine :

Presale Service:24h on line.

After Sale Service:24h on line,reply customers at any time when needed.

We had many customers over the world,such as Pakistan,Kazakhstan,South Africa,Botswana,Tanzania,Kenya,

Zambia,Malawi,Ghana,Namibia,Tanga,DR Congo,Benin,here are some of our Clients work site for reference:

Some customer work site: