Brick Making Machines

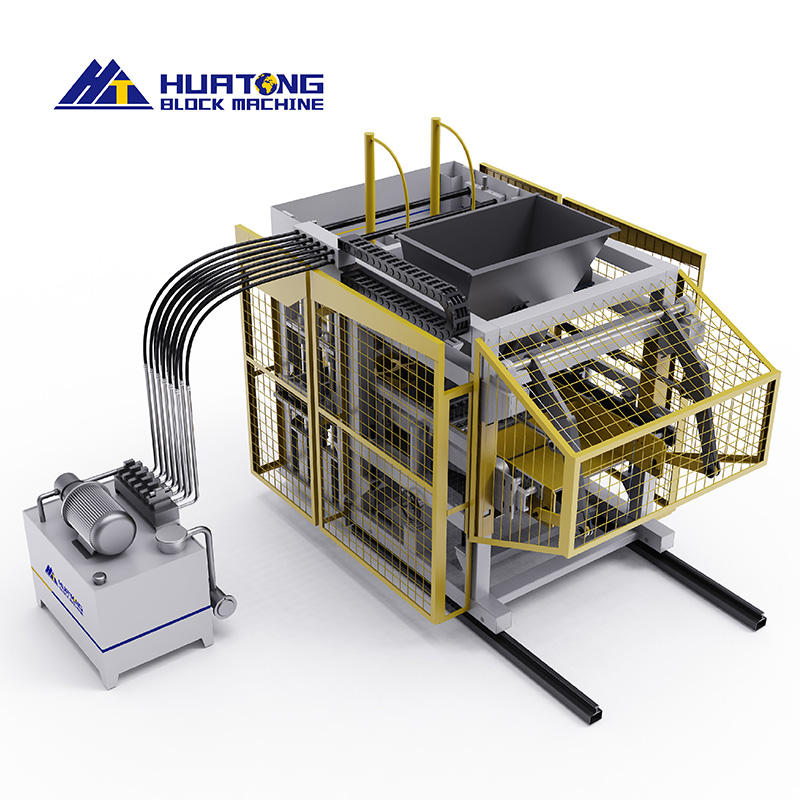

QT12-15 Brick Making Machines,the vibration adopts Principle of Resonant Centrifugal Force and it can be directional vibration.

The brick making machines adopts four galvanized pipe with sleeve bearing to ensure the exact movement of the mould.

Gear and shaft balance system can make male and female mould move stably.

Concrete feeder is revolving,convective and compulsive to ensure block density and reduce feeding cycle time.

Feeder moving is two curved arms driven by two cylinders,which makes feeder move quickly,durably,and steady.

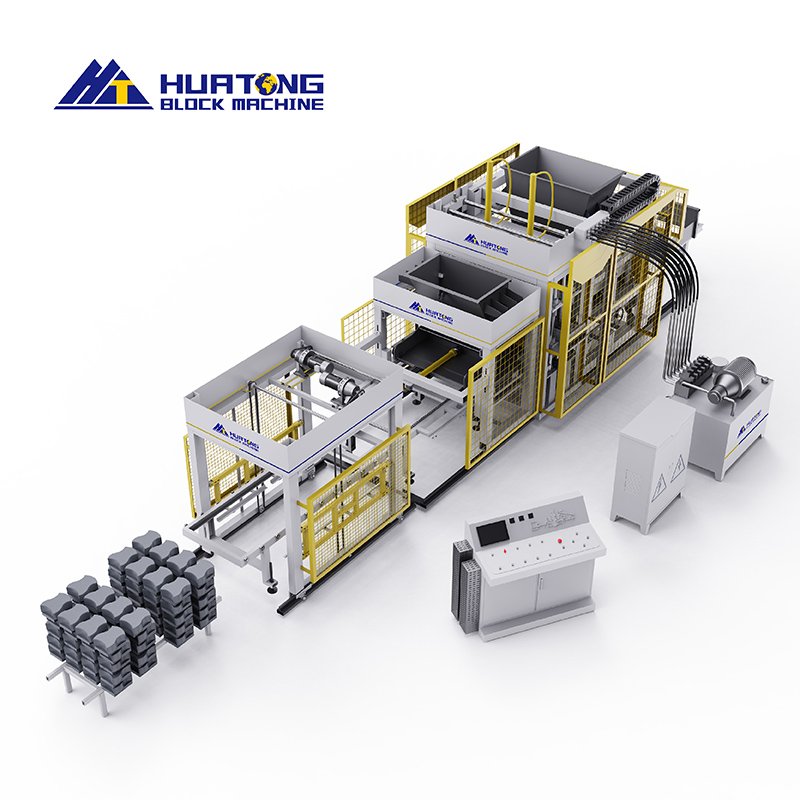

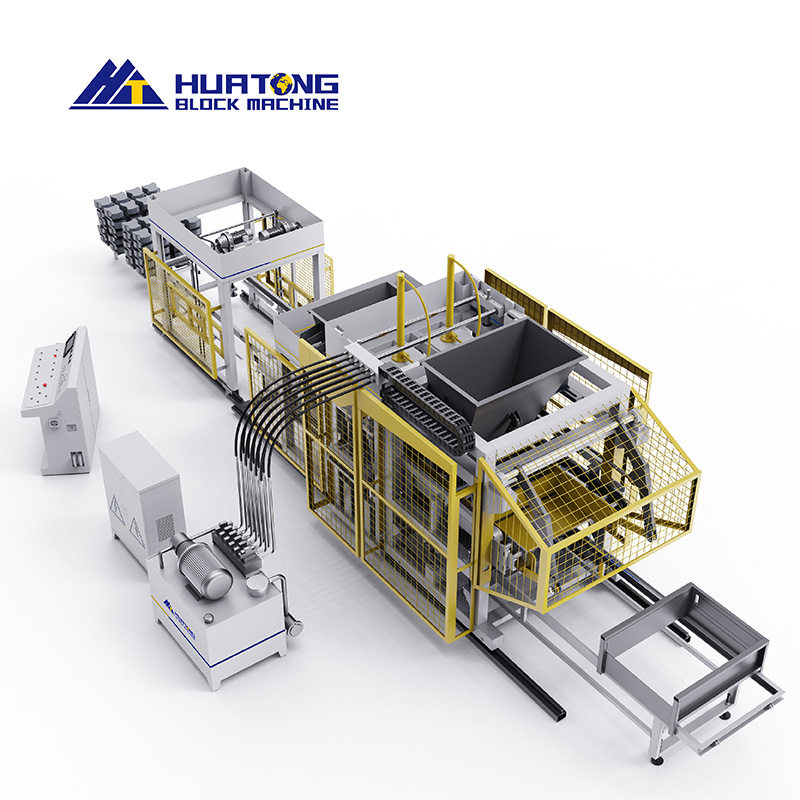

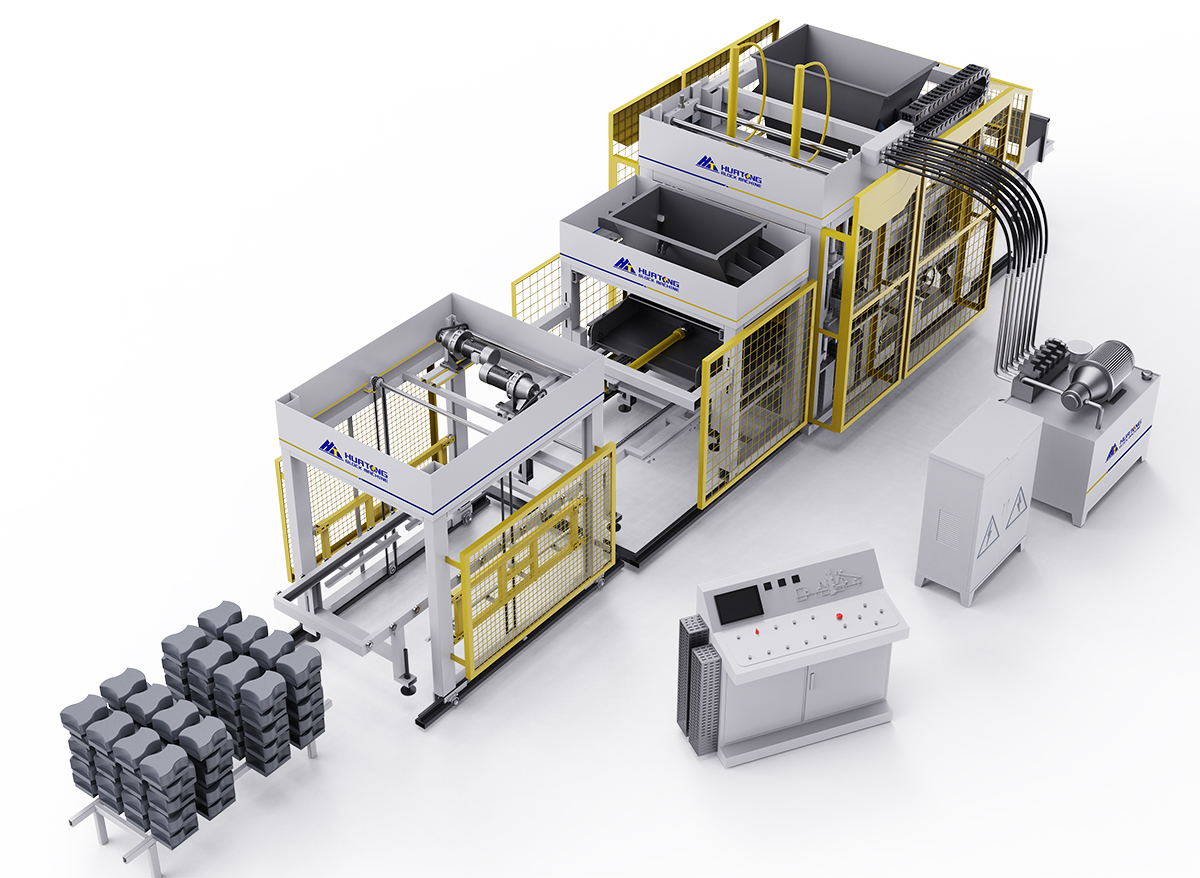

QT12-15 brick making machines is the one equipment designed, developed, processed and manufactured by Shandong Gaotang Huatong Hydraulic Pressure Co.,Ltd. in fully absorbing German advanced technology. All key electronic control components, motor reducers, hydraulic and pneumatic components are all well-known foreign brand products, so as to ensure the high reliability of equipment operation. The brick making machines is more user-friendly in terms of appearance design, structural design, and convenient operation. The performance of the brick making machines has reached the level of similar products in the world, but with good quality,and it is a general-purpose equipment for processing concrete products with excellent performance.

Brick Making Machines Technical Parameter:

| Dimension | 4000×2400×3200mm |

Mode of Vibration | Table Vibration |

Pallet Size | 1350×900mm*25-40mm |

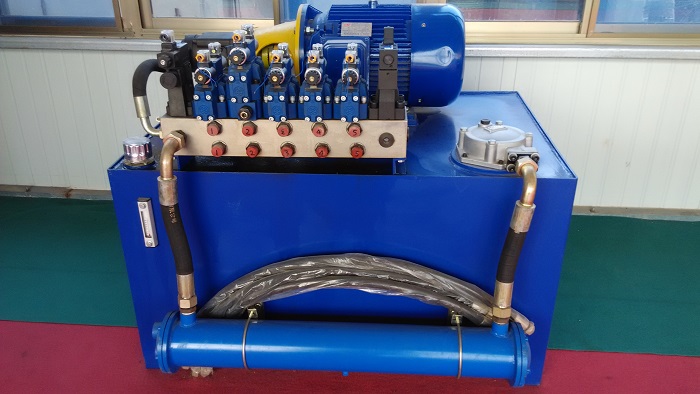

Rated Pressure | 21Mpa |

Oil Station Power | 22KW |

Cycle Time | 15-20S |

Mould Rockwell Hardness(HRC) | ≥55 |

Application Category | Construction industry: production of concrete hollow blocks, solid bricks, etc. |

Raw Material | Cement, sand and gravel, stone powder, stone nitrate, slag, slag and other building materials |

Production Capacity of Brick Making Machines:

Block Type | Picture | Size(L x W x H) | Pcs./Pallet | Cycle time | Pcs./8 Hours |

Hollow Block |  | 400x200x200mm | 12 | 15-20's | 17280-23040 |

Hollow Block | 400x150x200mm | 14 | 15-20's | 20160-26880 | |

| Hollow Block |  | 400x100x200mm | 22 | 15-20's | 31680-42240 |

Hourdi Block |  | 530x160x195mm | 9 | 15-20's | 11250 |

Stock Brick |  | 220x105x70mm | 48 | 15-20's | 86400 |

Paving Block |  | 200x100x60mm | 36 | 20-25's | 41470-51840 |

Paving Block |  | 225x112.5x60mm | 30 | 20-25's | 34560-43200 |

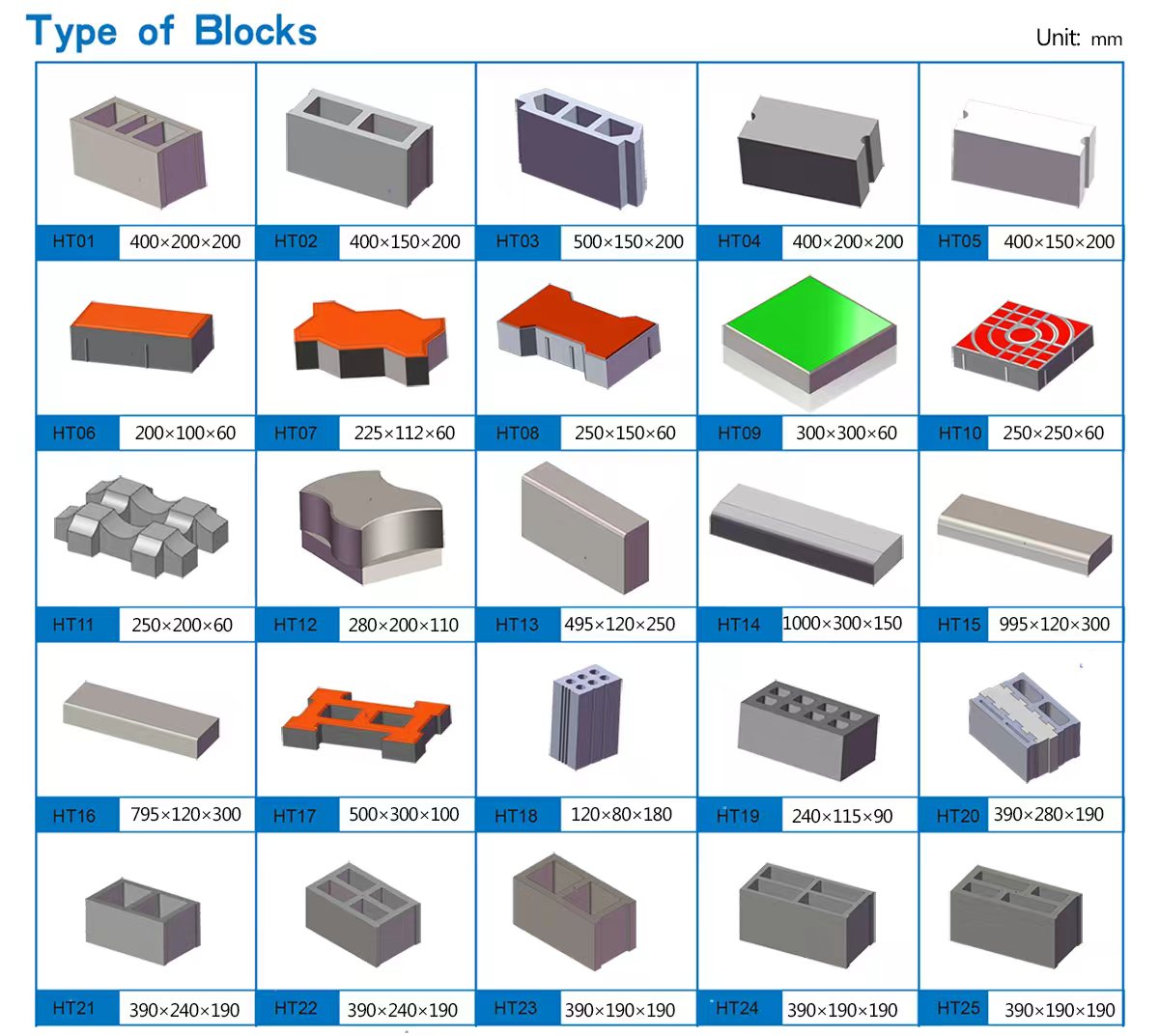

QT12-15 Brick Making Machines can produce different blocks by changing moulds,block size and type follow customrs requirement.

Such as solid blocks,hollow blocks,paving blocks,interlocking blocks,kerbstone blocks and so on.

Block samles:

Performance Characteristics of Brick Making Machines:

High production efficiency: the use of high-efficiency hydraulic proportional valve system, double vane pump can make different actions at the same time, the molding cycle is shorter. | |

Good product quality: the vibration platform adopts the combination of dynamic and static technology, the vibration force is large, which can ensure the high density of concrete products, high compressive strength, frost resistance and good impermeability. | |

Mold locking device: The airbag locking mode is adopted, which can firmly lock the mold during the vibration and compaction stages, reduce the overall vibration of the machine, and make the product size more accurate and the structure stronger. | |

High degree of automation: equipped with PLC control system, simple operation, low failure rate, and fault diagnosis. | |

Easy maintenance: The whole machine adopts a split design, which is convenient for maintenance and maintenance and can reduce downtime. |

Packing and loading:

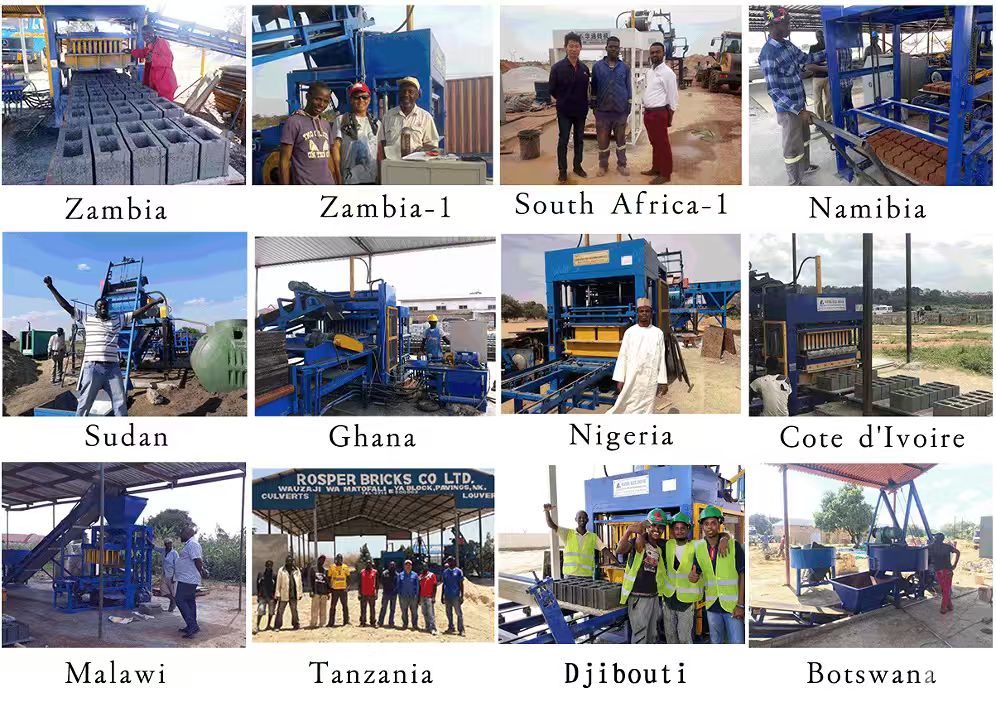

We have many customers all over the world,here is some of our customer work site for reference:

The enterprise has passed GB/T9001-2016/ISO9001-2015 quality management system certification, two integration management system evaluation certificate.

Shandong Huatong Hydraulic Machinery Co., Ltd. (hereinafter referred to as "Shandong Huatong") was founded in 2004 and is located in Gaotang, Shandong Province. It is a scientific and technological enterprise focusing on the design, research and development, production and sales of bulk industrial solid waste comprehensive utilization equipment. It has intelligent production line of automatic block forming machine, automatic static pressure forming machine production line, aerated concrete block production line, vertical shaft planetary mixing station and other products, and waste scheme customization, preparation and operation services. It has member enterprises such as Huatong Machinery, Avante Machinery, Darun Environmental Protection, Cote d'Ivoire Shandong Group Company, and more than 270 engineers and technicians of all kinds.