Concrete Mixing Machine

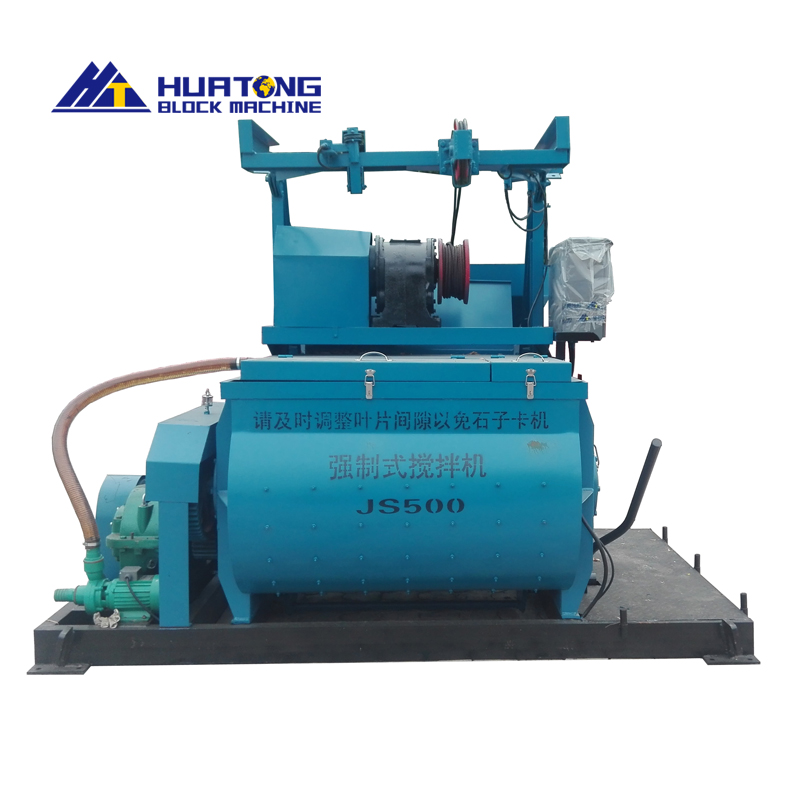

The JS500 series concrete mixer is a twin-shaft forced mixer that can mix dry concrete, plastic concrete, fluid concrete, lightweight aggregate concrete, and various types of mortar. It has a wide range of applications.

In summary, the Huatong JS500 concrete mixer is an exceptional, high-performance, and stable concrete mixing equipment. Its stable operation, thorough mixing, high production capacity, ease of maintenance and repair, and versatility make it an ideal choice for construction projects. If you’re looking for an efficient and reliable concrete mixing equipment, the Huatong JS500 certainly deserves consideration.

Product Details

The Huatong JS500 type concrete mixer is a twin-shaft forced type mixer primarily used for producing concrete.

The JS500 concrete mixer features a well-designed structure, strong mixing action, excellent mixing quality, high efficiency, low energy consumption, novel layout, high degree of automation, and ease of use and maintenance.

Technical Parameters

| Model | JS500 | |

| Discharging Capacity (L) | 500 | |

| Feeding Capacity (L) | 800 | |

| Productivity (m³/h) | ≥25 | |

| Maximum Aggregate Size (Gravel/Crushed Stone) (mm) | 80/60 | |

| Mixing Blade | Rotation Speed (r/min) | 35 |

| Quantity | 2 X 7 | |

| Mixing Motor | Model | Y180M-4 |

| Power (KW) | 18.5 | |

| Hoist Motor | Model | YEZ132S-4-B5 |

| Power (KW) | 5.5 | |

| Water Pump Motor | Model | 50DW20-8A |

| Power (KW) | 0.75 | |

| Hopper Lifting Speed (m/min) | 18 | |

| Overall Dimensions (Length×Width×Height) | Transport State | 3050X2300X2680 |

| Working State | 4461X3050X5225 | |

| Overall Mass (kg) | 4000 | |

| Discharging Height (mm) | 1500 | |

Product details display

1. Highly efficient and stable mixing power.

Huatong JS500 mixer, a powerful stirring power equipment. Its stable operational characteristics are due to a sophisticated design and strict manufacturing process. This mixer can withstand high intensity concrete stirring tasks, ensuring the stirring quality of the concrete. Whether in the city's high-rise building construction, or in the rural self-built housing projects in the countryside, Huatong JS500 Mixer is an indispensable important role.

2. Unparalleled stirring uniformity

Another notable feature of Huatong JS500 mixer is mixing uniformity. This equipment uses advanced stirring technology to fully mix various materials in the concrete to ensure the quality and performance of the concrete. Whether the embedding of coarse aggregates or the covering of fine aggregates can be effectively treated. This not only improves the strength and durability of the concrete, but also greatly reduces the concrete diseases on the site.

3. Ultra-high production

Huatong JS500 type mixing machine's high output is also a major advantage. In the case of construction projects, improving efficiency means being able to complete the project faster and reducing the waste of human and material resources. Huatong JS500 mixer can meet the needs of large engineering volume, even in busy construction sites can easily cope with. Its high output can not only shorten the construction cycle of the project, but also save a lot of costs for the enterprise.

4. Maintenance and maintenance convenience

Another major advantage of Huatong JS500 Mixer is convenient maintenance and maintenance. This not only reduces the maintenance cost of the enterprise, but also improves the utilization rate of the equipment. The structure of Huatong JS500 mixer is simple, easy to diagnose and repair. Even operators who are not familiar with the equipment can master the maintenance techniques of the equipment in a short time.

5. A variety of matching

Huatong JS500 mixer is not only powerful in performance, but also flexible in matching. It can be paired with different accessories to achieve different stirring effects according to different construction requirements. Whether it is dry mixing, wet mixing, or adding additives, Huatong JS500 type mixer can easily cope with. This allows it to achieve maximum efficiency in a variety of construction projects.

To sum up, Huatong JS500 mixer is an excellent performance, efficient and stable concrete mixing equipment. Its stable operation, uniform stirring, high yield, convenient maintenance and diverse mixing characteristics make it an ideal choice in construction projects. If you are looking for an efficient and reliable concrete mixing equipment, then Huatong JS500 mixer is definitely worth considering.

FAQ

1. What are the power and voltage requirements for the JS500 mixer?

It typically uses a 30-37kW motor (380V/50Hz three-phase power) to drive the twin shafts. Ensure a stable power supply to avoid low mixing efficiency or motor damage during continuous operation.

2. Is the JS500 mixer easy to install and operate?

Yes, its compact design facilitates on-site installation with minimal foundation work. The control system (manual or semi-automatic) is easy to operate; basic operator training is sufficient to set parameters and monitor the mixing process.

3. Can the JS500 mixer handle aggregates of different sizes?

It can handle aggregates with a maximum size of 60mm, suitable for common building materials such as gravel, crushed stone, and sand. For larger aggregates, please consult the manufacturer for custom modifications.

4. What safety features does the JS500 twin-shaft mixer have?

It is equipped with an emergency stop button, safety guards for rotating parts, and motor overload protection. When the mixing drum cover is opened, the interlocking system will prevent the equipment from operating, thereby ensuring the safety of the operators.