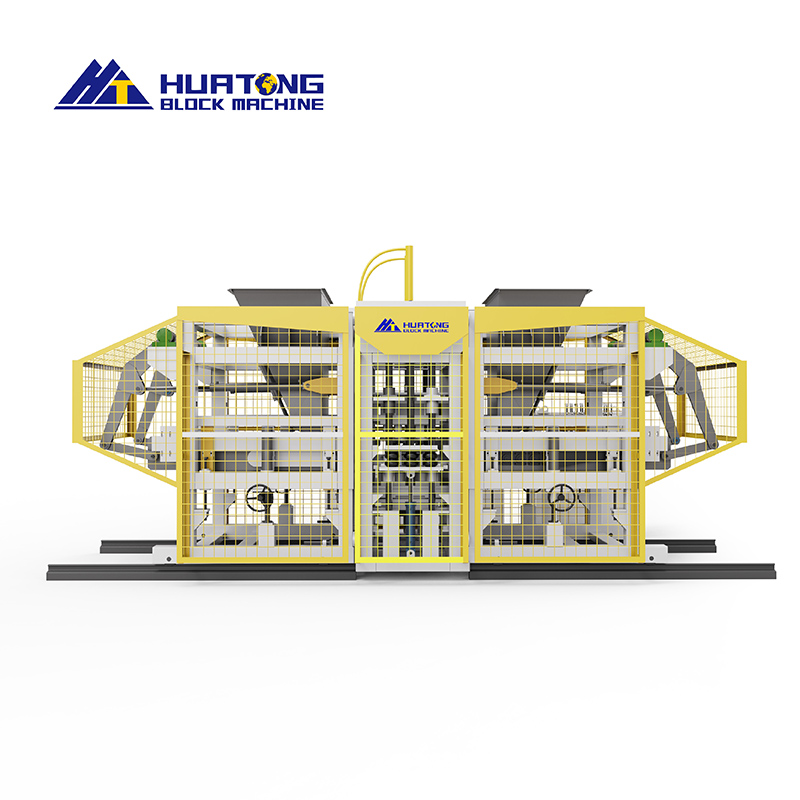

Automatic Block Making Machine

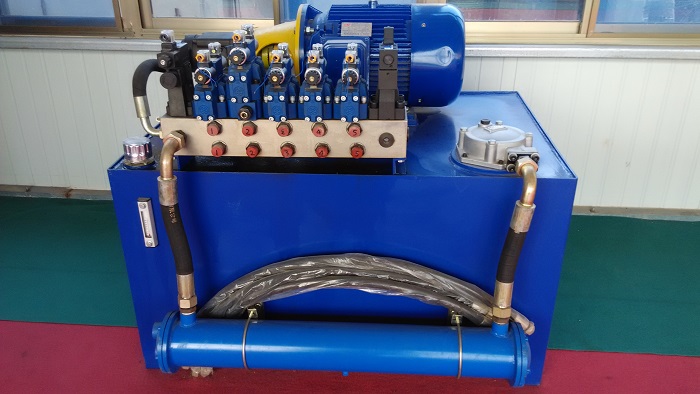

QT15-15 Automatic Block Making Machine ,the hydraulic system adopts Proportion Direction Valve.The valve can adjust flow rate and buffer cylinder during the process of production.Therefore, automatic block making machine can protect cylinder and extend life,and improve the speed and flexibility of each part.

The automatic block making machine mould is made with heat treatments of quenching,tempering, carbonization and boriding.Working life of mould is improved.

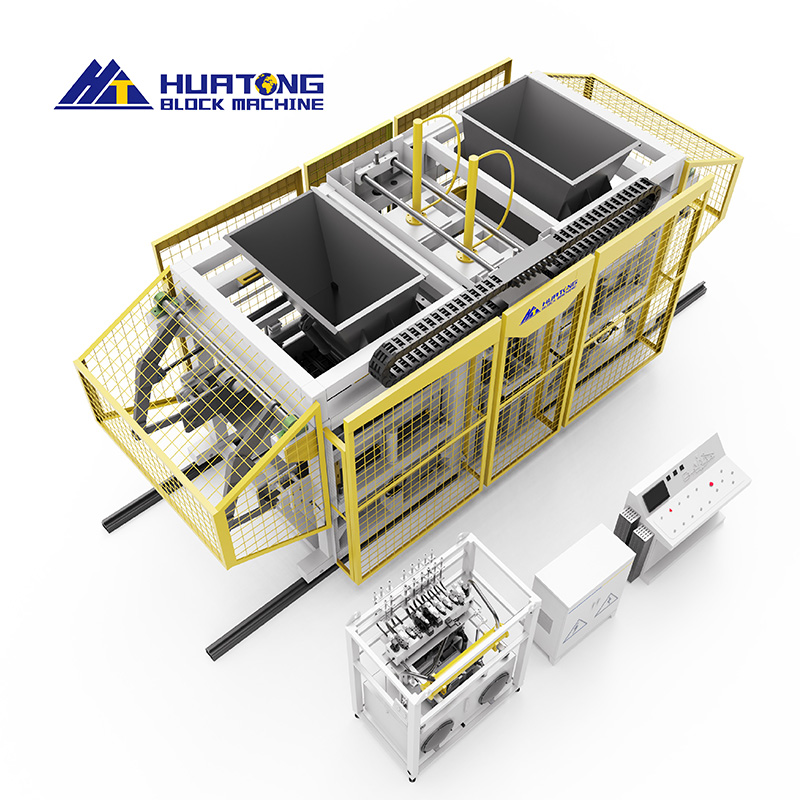

QT15-15 automatic block making machine is the one large concrete brick making production equipment, automatic block making machine using strong vibration system, hydraulic locking device, and air bag clamping system.automatic block making machine have large output, stable performance, high degree of automation, automatic block making machine is the one widely favored block making machine by many customers.

Main Technical Parameters of Automatic Block Making Machine :

| Dimension | 4170*2650*3260mm |

| Mode of Vibration | Table Vibration |

| Pallet Size | 1350*1150*25-40mm |

| Rated Pressure | 21Mpa |

| Oil Station Power | 22KW |

| Cycle Time | 15-20's |

| Mould Rockwell Hardness(HRC) | ≥55 |

| Application Category | The QT15-15 model is a hydraulic, fully automatic brick-making machine that can be used for multiple purposes, fully meeting the diverse demands of the market. The block products have excellent compressive strength, precise appearance dimensions, and low dispersion, ensuring that the strength of each block can be guaranteed. This series of equipment employs closed belt conveyors, strictly controlling the small material semi-storage volume, allowing materials to be delivered and used immediately, preventing concrete from liquefying prematurely due to aftershocks and ensuring the strength of the products. |

| Raw Material | Cement, sand and gravel, stone powder, stone nitrate, slag, slag and other building materials |

Capacity of Automatic Block Making Machine:

Block Type | Picture | Size(L x W x H) | Pcs./Pallet | Cycle Time | Pcs./8 Hours |

| Hollow Block |  | 400x200x200mm | 15 | 15-20's | 21600-28800 |

| Hollow Block |  | 400x150x200mm | 18 | 15-20's | 25900-34500 |

| Hollow Block |  | 400x100x200mm | 24 | 15-20's | 34500-46000 |

| Paving Block |  | 200x100x60mm | 54 | 20-25's | 62200-77700 |

| Paving Block |  | 225x112.5x60mm | 35 | 20-25's | 40300-50400 |

Advantage of Automatic Block Making Machine :

The automatic block making machine vibration adopts Principle of Resonant Centrifugal Force and it can be directional vibration. The automatic block making machine adopts four galvanized pipe with sleeve bearing to ensure the exact movement of mould.Automatic block making machineGear and shaft balance system can make male and female mould move stably. | |

The automatic block making machine Concrete feeding is revolving,convective and compulsive to ensure block density and reduce feeding cycle. Feeder moving of automatic block making machine is two curved arms driven by two cylinders,which makes feeder move quickly,durably,and steady. | |

The automatic block making machine hydraulic system adopts Proportion Direction Valve.The valve of automatic block making machine can adjust flow rate and buffer cylinder during the process of production.Therefore,it can protect cylinder and extend life,and improve the speed and flexibility of each part. |  |

The automatic block making machine vibration system adopts German Frequency Conversion Technique.The vibration motor of automatic block making machine is Frequency Conversion Controlled.The lubrication of Vibrator adopts oil immersed,which improve the using life of Bearing and Gear of vibrator. | |

Automatic block making machine Adopting International Advanced Microcomputer Control Technology to make Machine and electrical equipment to be one part.The plant can work automatically and cyclically.Our technicians put fault diagnosis,problem alarming into computer by safety logic control.The screen will timely and accurately show fault and methods to client if the machine is in error. |  |

QT15-15 Automatic Block Making Machine Production Line Packing and Loading:

The enterprise has passed GB/T9001-2016/ISO9001-2015 quality management system certification, two integration management system evaluation certificate.

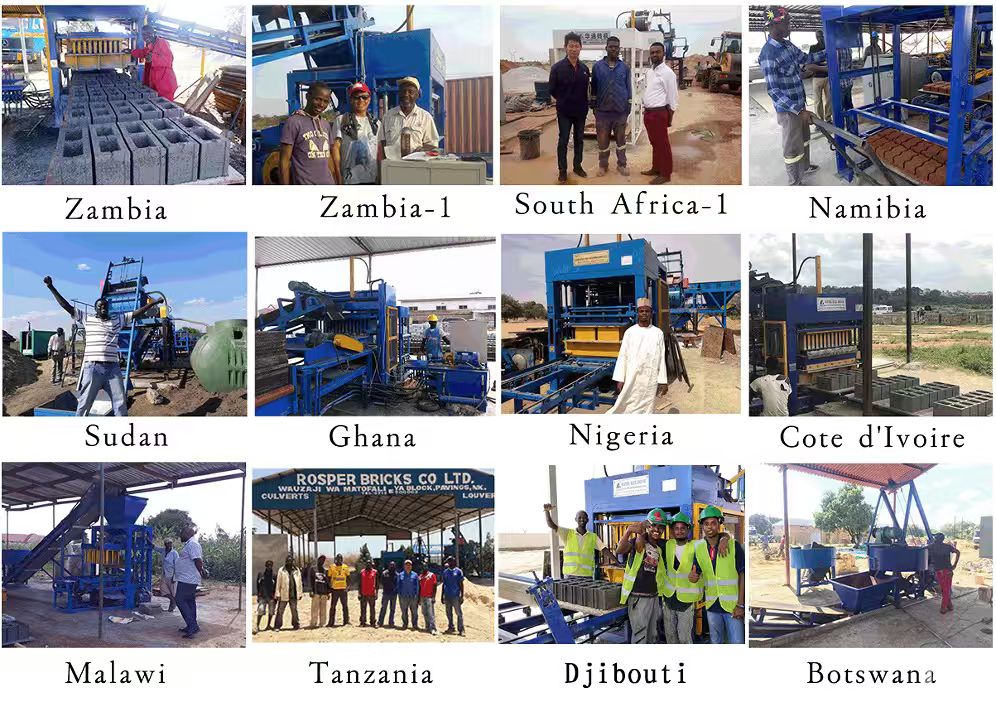

We had many customers over the world since 2004,such as Pakistan,Kazakhstan,South Africa,Botswana,Tanzania,

Kenya,Zambia,Malawi,Ghana,Namibia,Tanga,DR Congo,Benin,here are some of our Clients work site for reference:

Clients work site:

We offer an on-site troubleshooting guarantee. If a device issue cannot be resolved by phone, Huatong will immediately dispatch a technician to address it.

Our factory picture:

Welcome all over the world customers to visit our factory to discuss more details.