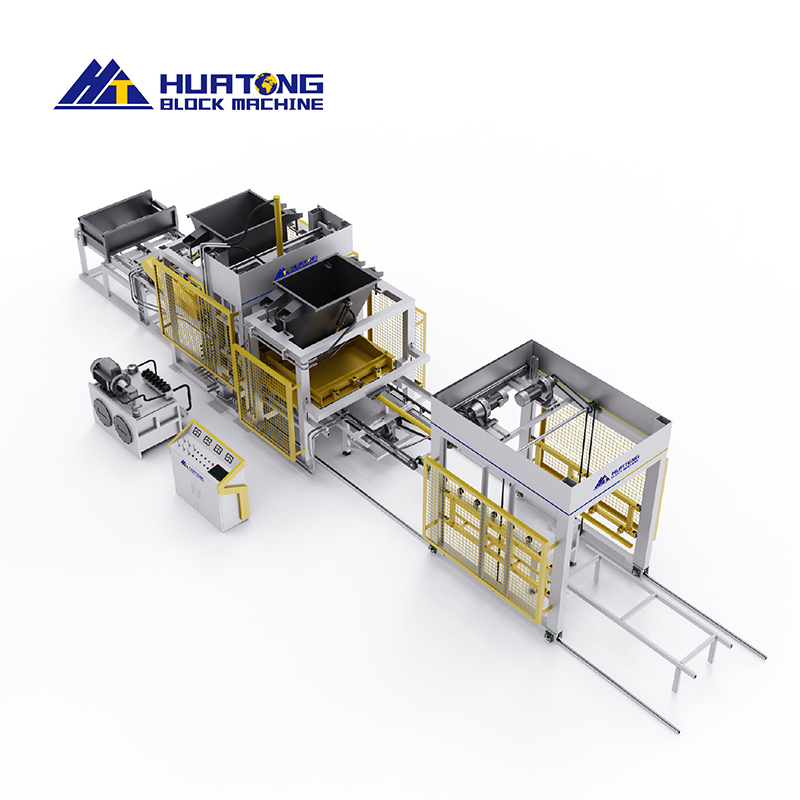

Brick Block Making Machine

Precision-Guided Balancing System: Incorporates a robust four-bar linkage mechanism, integrated with extended guide sleeves, to ensure exceptional alignment and precise movement between male mould and female mould.

Optimized Concrete feeder: A combination of rotating convection and forced feeding ensures uniform concrete distribution, resulting in enhanced brick density while significantly reducing cycle times. This process is driven by a highly reliable gear transmission system for unwavering operational stability.

Intelligent Stacker with Frequency Conversion: Equipped with advanced frequency conversion technology, the stacker intelligently regulates operational speed. This delivers smooth acceleration and deceleration, perfectly coordinated motion, and remarkable operational flexibility.

Brick block making machine is one kind of high efficiency construction brick production equipment.It works through automatic concrete feeding,hydraulic pressing,vibration,moulding,demoulding,wet block transport.Brick block making machine is one professional equipments which produces concrete or sand,aggregates to be hollow block,solid block,curbstone and paving blocks.The advantages of brick block making machine is that it is high production capacity and same block dimension.

Production Capacity of QT10-15A Automatic Brick & Block Making Machine

| Block Type | Size(L x W x H) | Picture | Pcs./Pallet | Pcs./8Hours | ||

| Hollow Block | 400x200x200mm |  | 10 | 15000 | ||

| Hollow Block | 400x150x200mm |  | 12 | 18000 | ||

| Hollow Block | 400x100x200mm | 16 | 27000 | |||

| Holland Paving Block | 200x100x60mm |  | 35 | 52500 | ||

Technician Parameter of QT10-15A Automatic Brick & Block Making Machine

| Dimension | 5400x2050x3050mm | Weight | 14000KGS | |||

| Pallet Size | 1150x900mm | Performance Standard | JC/T920-2011 | |||

| Mode of Vibration | Table Vibration | Vibration Frequency | 4200r/min | |||

| Vibration Force | 100KN | Cycle Time | 15-25Sec. | |||

| Hydraulic Motor | 18.5kw-4P | Vibration Motor | 7.5kw-2P x2 | |||

| Concrete Feeder Motor | 4kw-23-4P | Belt Conveyor Motor | 2.2kw-43-4P | |||

| Wet Block Conveyor Motor | 1.5KW-35-4P | Stacker Motor | 1.5kw x2 | |||

| Power | 44.2kw | |||||

Product Details of QT10-15A Automatic Brick & Block Making Machine

|  |

| Vibrator of brick & block machine is the core compaction tool for making blocks. It compacts loose concrete in mold cavity through high-frequency vibration. It has built-in high-quality eccentric shaft, synchronous gears and sealed bearings, which can withstand the continuous load under high-frequency vibration. It improves internal structural density and final compressive block strength. | Machine frame is made of extremely strong steel and employs advanced welding techniques, resulting in a robust, durable, and stable structure. |

|  |

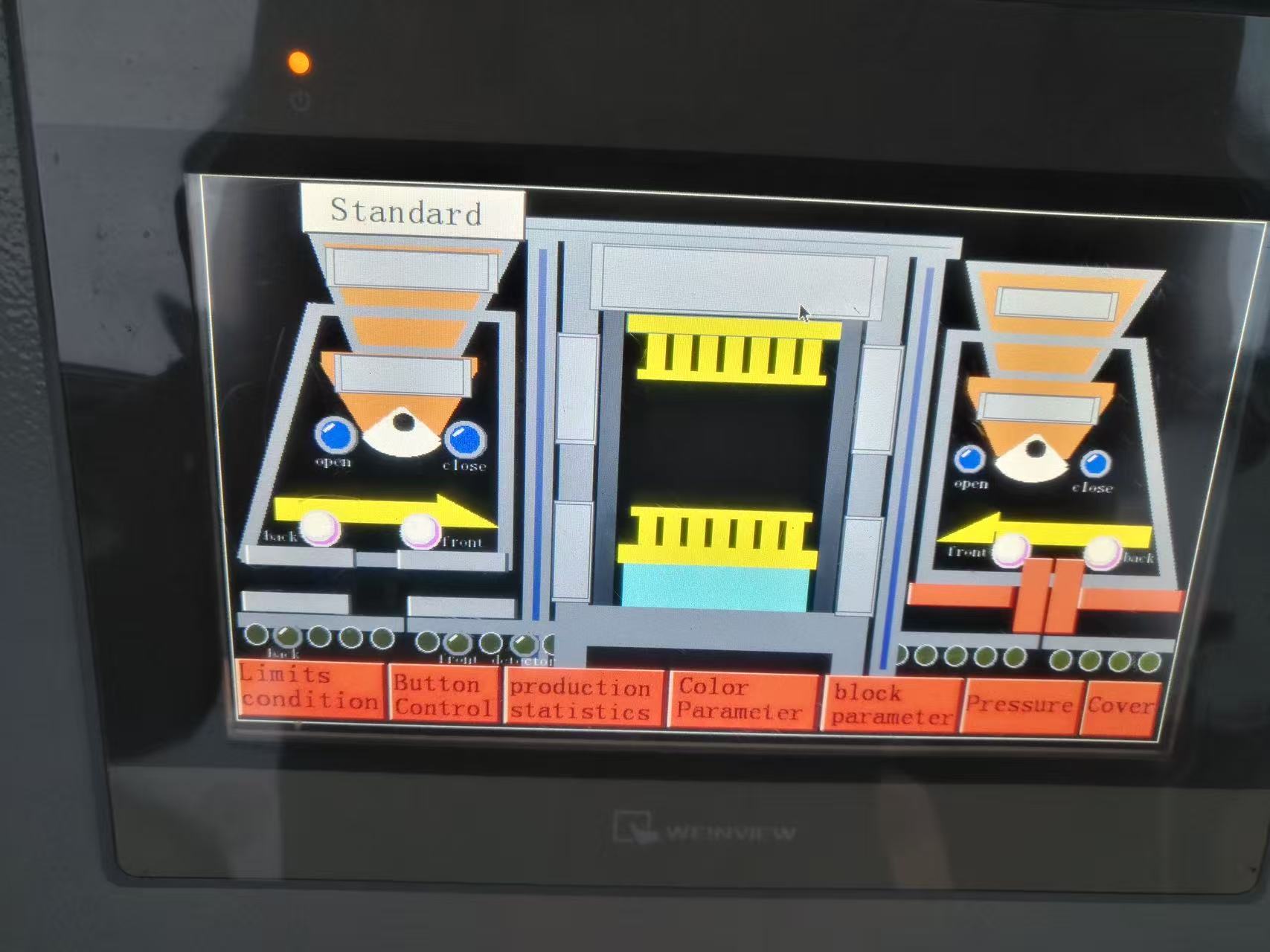

| The machine is easy to operate and maintain. PLC control system is equipped with complete logic control, production programs, fault diagnosis system and remote control system. Operators can operate it after simple training. | The machine is high degree of automation.It is Equipped with PLC intelligent control system and a touch screen human-machine interface.It can realize manual or automatic control. The processes of concrete feeding, vibration, molding, demolding, pallet loading and unloading, and stacking can all be completed automatically, reducing labor costs and improving production efficiency. |

Customer Case of QT10-15A Automatic Brick & Block Making Machine

|  |

| China | China |

Working video of QT10-15A Automatic Brick & Block Making Machine