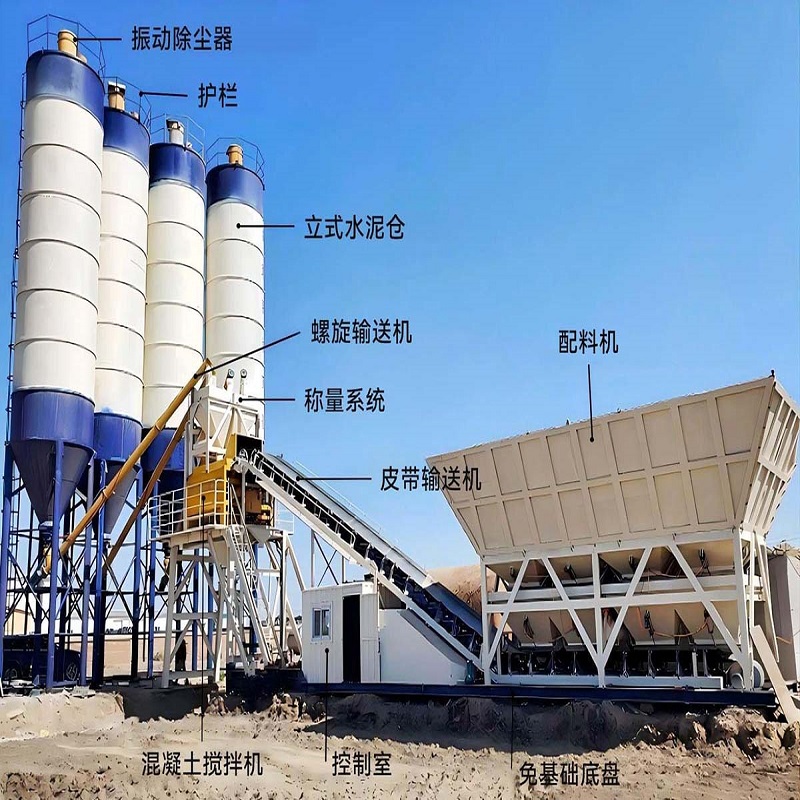

shaft concrete mixing station

The construction concrete batching plant is a complete set of automated concrete production equipment. Its core advantages lie in its low investment cost, compact footprint, and easy assembly, disassembly, and transportation.

Its application scenarios cover small and medium-sized construction projects and commercial concrete production. Specifically, it can be used in hydropower projects, airport projects, highway construction, bridge construction, and main building construction. It can also provide concrete support for the production of pipe piles, cement pipes, and brick machines.

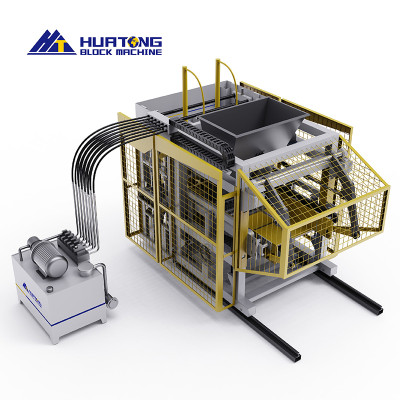

Equipped with a vertical-shaft planetary mixer, the equipment not only produces high-quality concrete but also shortens the mixing cycle, significantly improving production efficiency. The accompanying control system is easy to use and operates stably and reliably. It also features a variety of practical functions, including re-weighing, re-weighing, continuous production, and intelligent alarms.

To meet the diverse needs of our customers, we offer a variety of customized design and installation solutions to ensure the equipment is precisely matched to your specific production requirements.

HZN180 shaft concrete mixing station

The core advantages of engineering concrete batching plants lie in three main dimensions: controllable cost, strong adaptability, and stable efficiency. Specifically, these can be summarized in four points:

1. Lower Investment and Site Costs: The overall equipment investment is lower, suitable for small and medium-sized production needs; the compact footprint eliminates the need for large-scale site planning, flexibly adapting to space-constrained environments such as urban areas and construction sites.

2. More Flexible Relocation and Assembly: The equipment's structural design facilitates disassembly and transportation, allowing for rapid relocation to new sites after project completion; the simple assembly process eliminates complex construction, shortening the equipment commissioning preparation cycle.

3. Dual Guarantee of Production Efficiency and Quality: Equipped with a vertical shaft planetary mixer, the mixing cycle is short, resulting in high homogeneity of the finished concrete and reducing quality issues; the accompanying control system is easy to operate, supporting functions such as re-weighing and continuous production, reducing reliance on manual labor and avoiding human error.

4. Stronger Demand Adaptability: Customized design and installation solutions can be provided for different scenarios such as hydropower, highways, and precast components; it can meet the temporary production needs of small and medium-sized construction projects as well as support a stable supply of commercial concrete, with a wide range of applications.