Concrete Bricks Pallet

Concrete Bricks Pallet:

Custom Pallet Solutions for Unfired Brick Machines

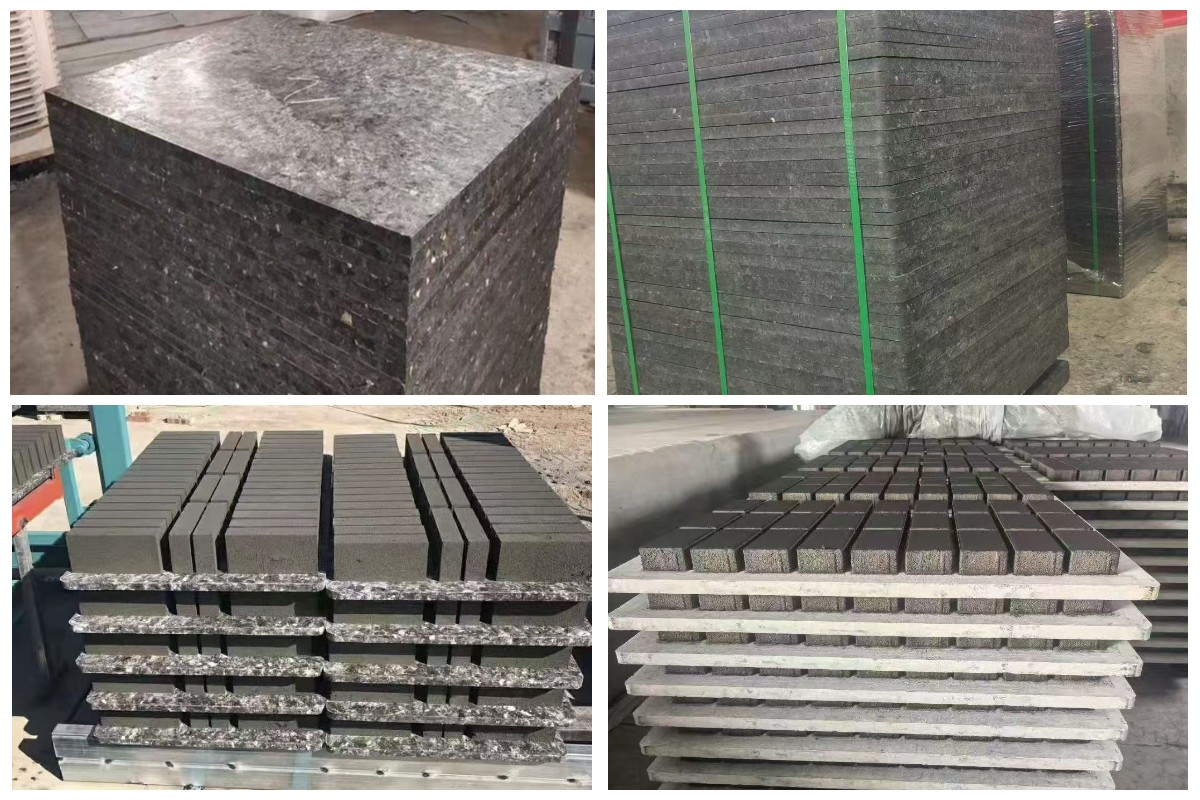

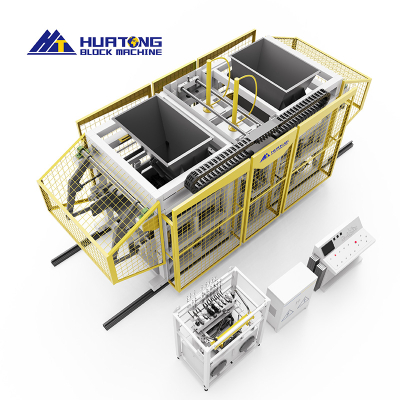

Huatong provides engineered pallet configurations tailored to specific mold dimensions and production parameters. Our customization capabilities include:

Dimensional Flexibility: Support for non-standard specifications (1100×550mm to 1700×850mm)

Thickness Optimization: Adjustable profiles (18mm/22mm+)

Production Integration: Precision matching with brick machine output requirements

Optimized long-term operational expenditure

Ten Core Advantages of RPV Pallets

Superior Temperature Resistance:** Withstands high-temperature steam curing above 200℃, maintaining structural stability.

Embedded Steel Structure:** Manganese steel frame and polymer material composite casting eliminates the risk of delamination.

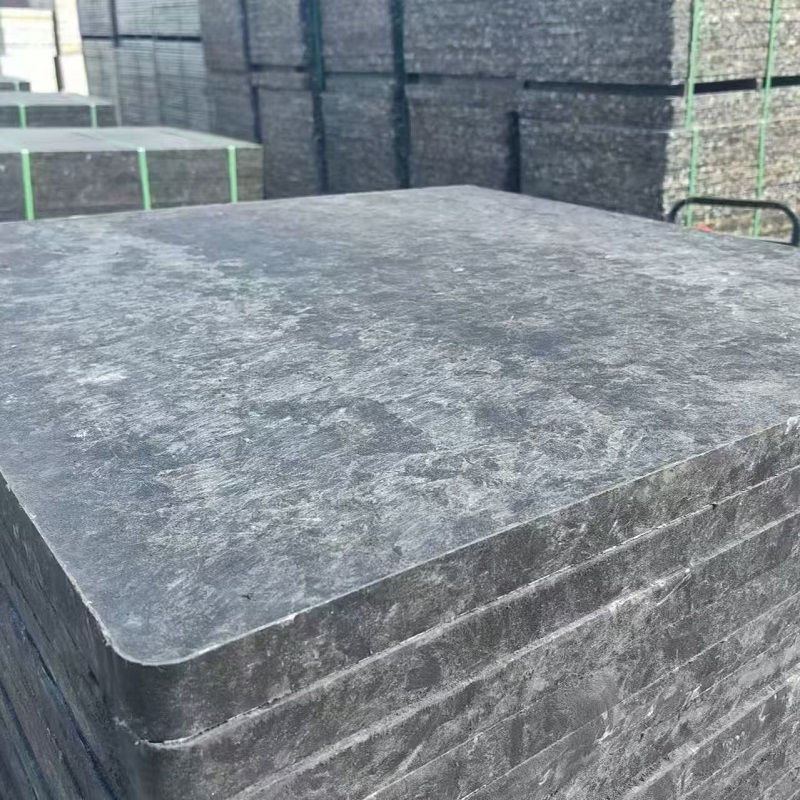

Vibration and Fatigue Resistance:** No edge detachment observed after 1 million cycle tests.

Corrosion-Resistant Design:** Fully enclosed steel structure prevents rust contamination of concrete products.

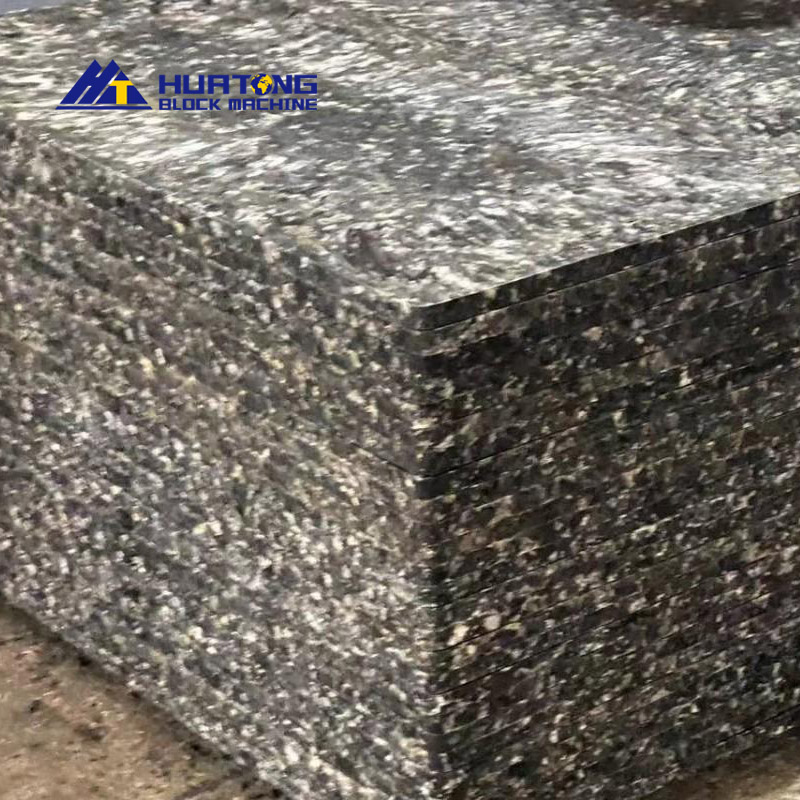

Ultra-High Flatness Precision:** Flatness error ≤0.3mm/m, ensuring component forming quality.

Long Lifespan:** Lifespan of 8-10 years under normal use conditions (5 times that of wooden pallets).

Automated Adaptability:** Precise dimensions combined with robotic gripper and conveyor systems.

Maintenance-Free:** No rust prevention treatment or special maintenance required.

Multi-Scenario Applicability:** Compatible with steam curing kilns, automated storage and retrieval systems, and assembly line environments.

Comprehensive Cost Optimization:** Although the unit price is higher, the cost per use is reduced by more than 60%.