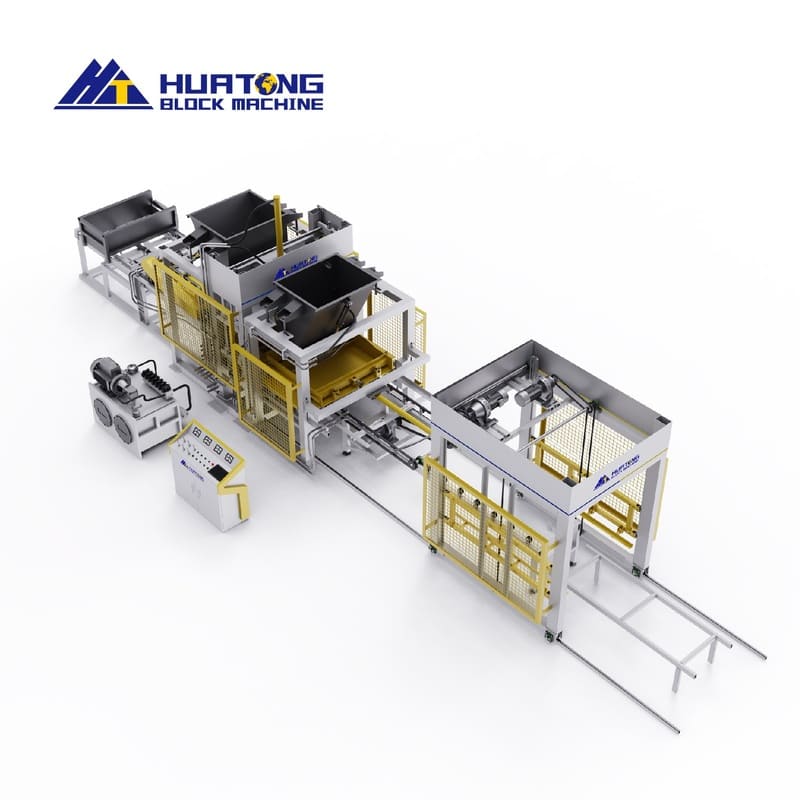

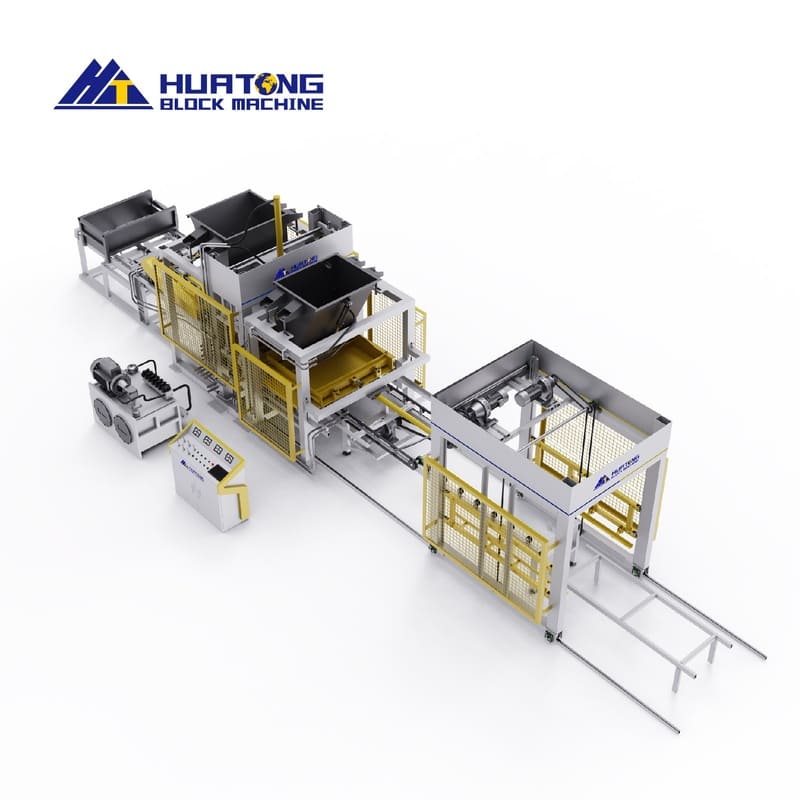

Automatic Block Brick Machine

Model: QT7-15

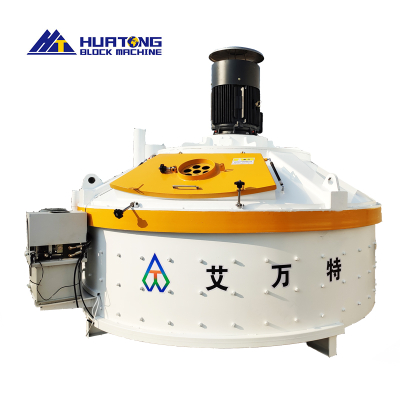

As a professional Automatic block brick machine manufacturer, you can purchase our machine from us with confidence. We will provide you best after-sales service and timely delivery for QT7-15 Block making machine. cement block machine (also known as a cement brick machine, brick machine, block machine, or briquette machine) is a mechanical device used to mix and press materials such as sand, cement and quarry dust into bricks or blocks of various specifications.

Cement Brick machine is an economical, small-scale cement brick manufacturing machine independently developed and manufactured by Huatong for over 20 years. Widely praised by customers worldwide, it is a proven and cost-effective brick making machine suitable for starting a concrete brick manufacturing business. The machine is easy to operate and offers reliable performance. Various mold types can be customized to produce bricks of various specifications and sizes. The machine enables automated production, reducing labor costs. It also boasts very high production efficiency and high production accuracy, ensuring consistent brick specifications.

Technical Parameters

| Item | Specification |

Overall Dimensions | 3150*1900*2930 mm |

Molding Method | Table Vibration |

Pallet Size | 1150 × 750 mm |

Rated Pressure | 21 MPa |

Hydraulic Station Power | 18.5 kW |

Forming Cycle | 15–20 seconds per cycle |

Mold Rockwell Hardness | ≥ 55 HRC |

Applications | Construction Industry: production of concrete hollow and solid blocks. |

Raw Materials | Cement, sand, gravel, stone powder, limestone, slag, and other building materials. |

Production Capacity

| Product Type | Image | Size (mm) | Per Molding | Cycle Time | Daily Output (10 hrs) |

Hollow Block |  | 400 × 200 × 200 | 7 pcs | 15–20 s | 12,600–16,800 pcs |

Hollow Block |  | 400 × 150 × 200 | 8 pcs | 15–20 s | 14,400–19,200 pcs |

Hollow Block |  | 400 × 100 × 200 | 11 pcs | 15–20 s | 19,800–26,400 pcs |

Paving Brick |  | 200 × 100 × 60 | 30 pcs | 20–25 s | 43,200–54,000 pcs |

Paving Brick |  | 225 × 112.5 × 60 | 20 pcs | 20–25 s | 28,800–36,000 pcs |

Shipping logistics guarantee

FAQ

How is the raw material ratio determined?

The raw material ratio is determined based on the raw material characteristics, the type of brick being produced, and the performance requirements. Typically, experiments are conducted first, selecting different raw material ratios for trial mixing. Samples are then produced and tested for performance indicators such as strength, density, and water absorption. Based on these test results and combined with production experience, the raw material ratio is optimized. For example, in the production of ordinary load-bearing, unfired bricks, cement usage may be around 10%-15%, with fly ash and other industrial waste residues accounting for 60%-80%, and the remainder being aggregate. In actual production, the ratio may need to be adjusted appropriately based on factors such as fluctuations in raw material quality and equipment operating conditions.

Customer Case

Russia | Myanmar |