Block Bricks Mixer

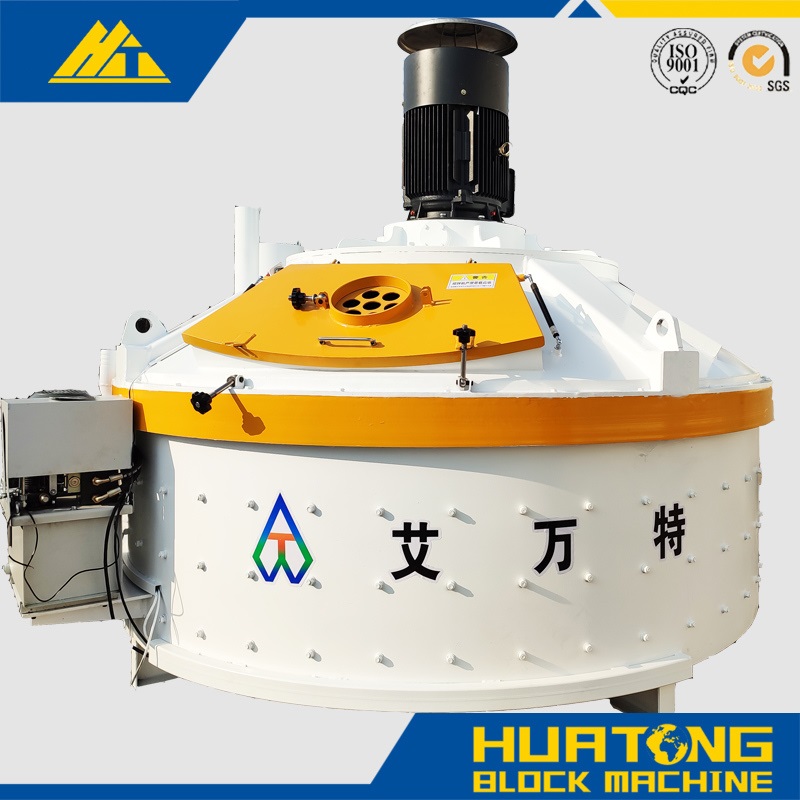

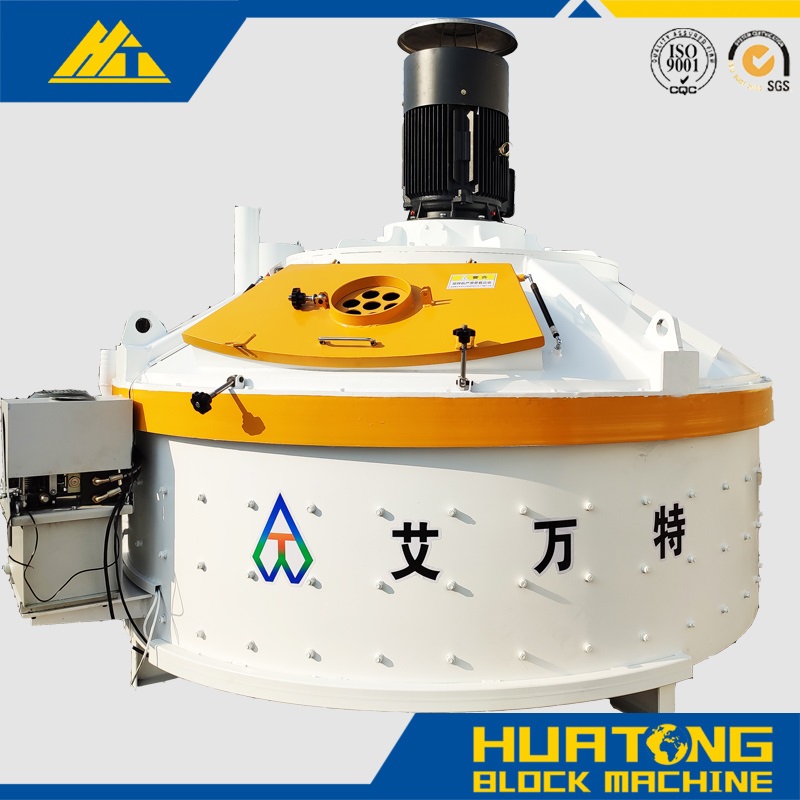

Model: MPG-1500 Block Bricks Mixer

99%+ mixing uniformity with fast cycles

Clean discharge without drum residue

Adaptable for lab R&D and full production

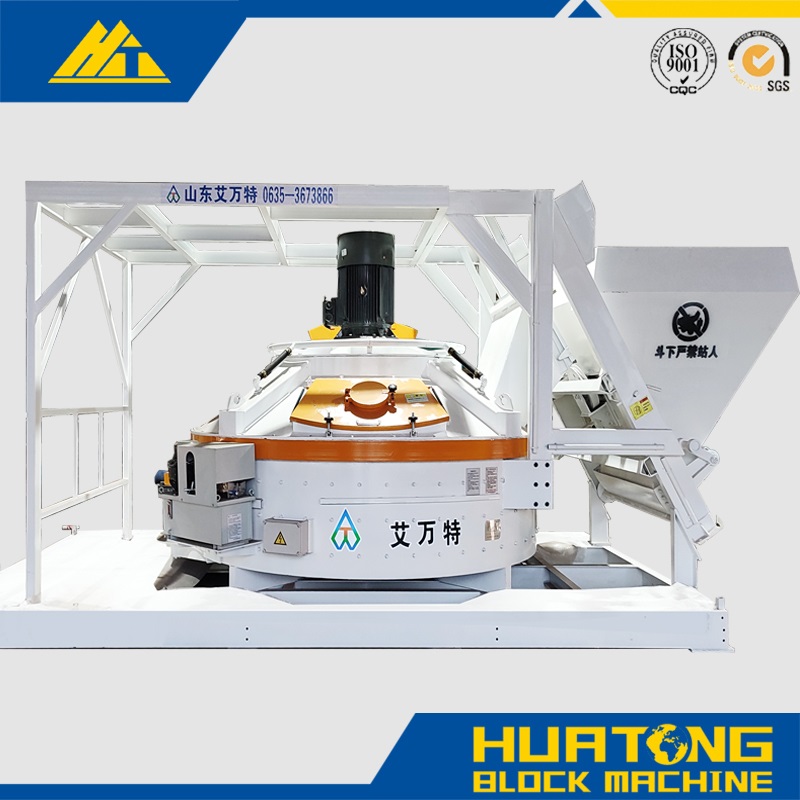

Compatible with automated brick systems

Partner with HUATONG for integrated mixing and forming solutions.

Block Bricks Mixer - Technical Features

Delivers high-capacity output with precision mixing homogeneity

Maintains consistent performance across all operational scales

Supports multi-line production through configurable discharge gates

Enables simultaneous batching for multiple mixing stations

Technical Parameter of MPG1500 brick machine

Specification | MPG1500 |

Feeding Capacity (L) | 2250 |

Discharge Capacity (L) | 1500 |

Discharge Mass (KG) | 3600 |

Mixing Rated Power (KW) | 55 |

Hydraulic Discharge Power (KW) | 3 |

Number of Planets/Blades | 2/4 |

Side Scraper | 1 |

Discharge Scraper | 1 |

Mixer Weight (KG) | 7700 |

Hoist Power (KW) | 18.5 |

Overall Dimensions (L*W*H mm) | 3230*2902*2470 |

Product details display

Lifting System: A wire rope pulls the lifting bucket via a winch and pulley mechanism. The feed gate on the mixer automatically opens during unloading and automatically closes when the bucket descends, preventing dust spillage during mixing and meeting environmental protection requirements. (Powder and water metering systems can be added upon request.) | |

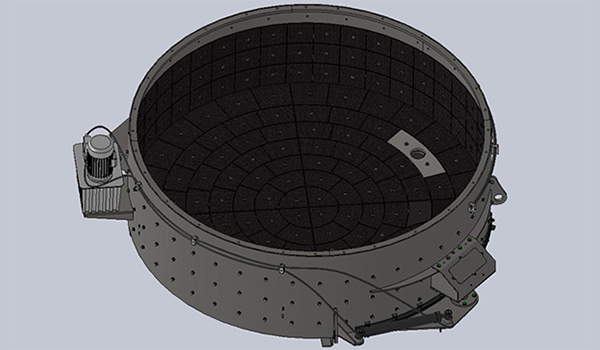

Mixing Drum Single-seam rolled steel construction Pressure-optimized weld placement Full-penetration welding Leak-proof integrity | |

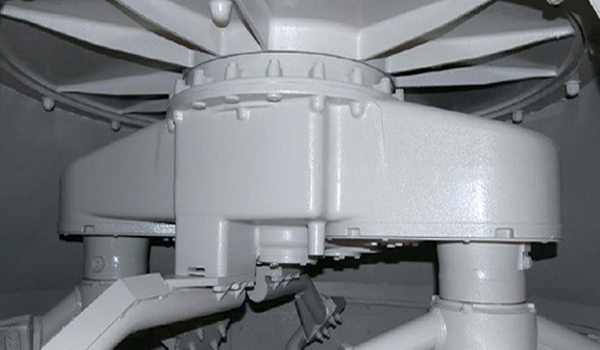

The planetary mixer features kinetically engineered asymmetrical mixing arms that systematically eliminate material dead zones during high-speed processing, delivering substantial improvement in homogenization efficiency | |

Dual-motion mixing arm Rotation + revolution Overlapping trajectories Zero dead zones Complete agitation |

Equipment application scenarios

Shipping and Logistics

Company Qualifications

Shipping and Logistics

FAQ

1. Equipment Features?

A: Supports multi-functionality, intelligent electronic control with human-machine interface, saving manpower, and suitable for different brick types and production

demands.

2. Customer On-Site Safety Training Includes?

A: Safety operating procedures mainly include pre-job training, wearing protective equipment, prohibiting hands from touching moving parts, equipment inspection,

and power disconnection during maintenance.