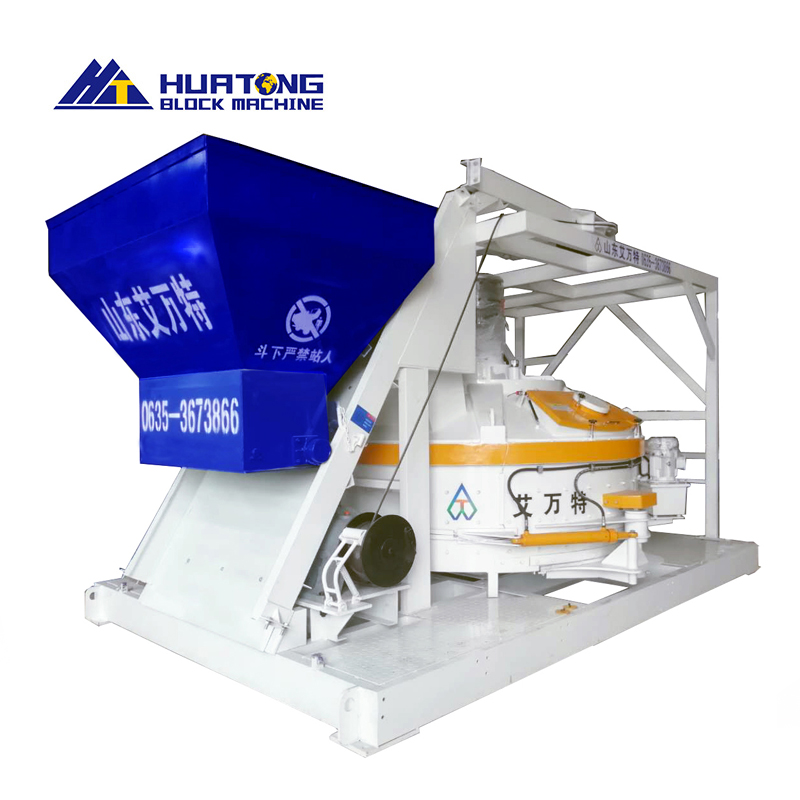

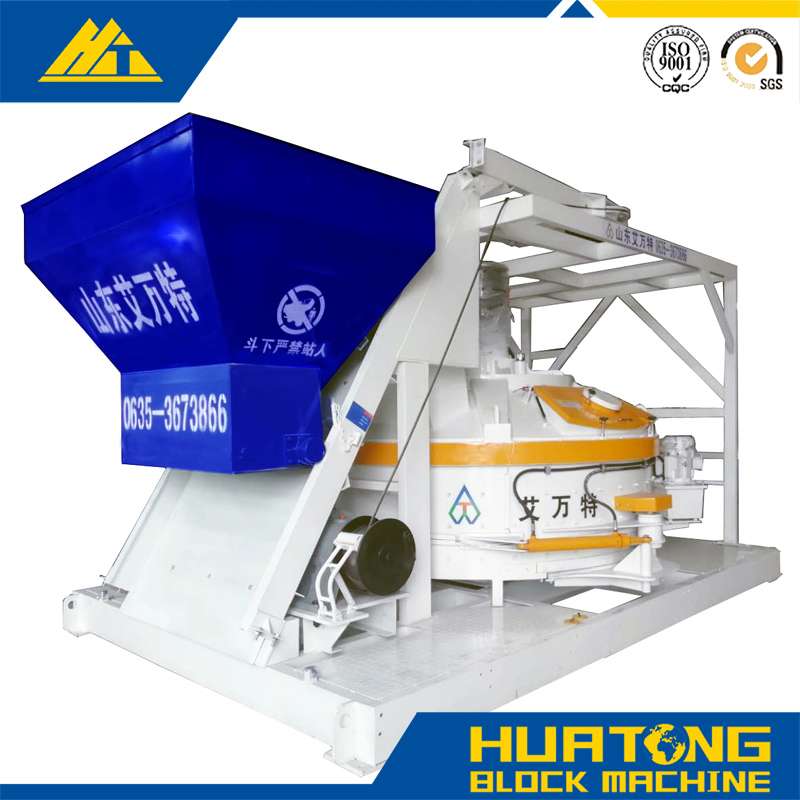

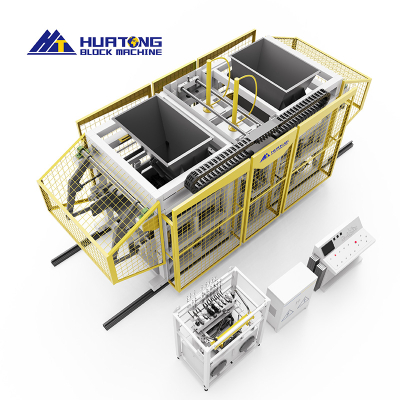

Vertical Shaft Mixer

Technical Advantages of MPG-1000 Vertical Shaft Mixer:

High Efficiency & Scalable Performance: Ensures uniform mixing quality and high throughput across all batch sizes. Configurable with multiple discharge gates for simultaneous servicing of multiple production lines in concrete batching plants.

Robust & Low-Maintenance Operation: Compact design with sealed construction prevents shaft leakage, ensuring operational stability, minimal downtime, and reduced long-term maintenance costs.

Gentle yet Thorough Mixing Action: Planetary movement mechanism enables homogeneous blending without material degradation, segregation, or agglomeration, preserving material integrity and performance.

Advantages:

Advanced manufacturing with global technologies

High efficiency & compact design for all concrete types

Energy-saving & environmentally friendly

Reliable standalone or mixing plant integration

Product Advantages

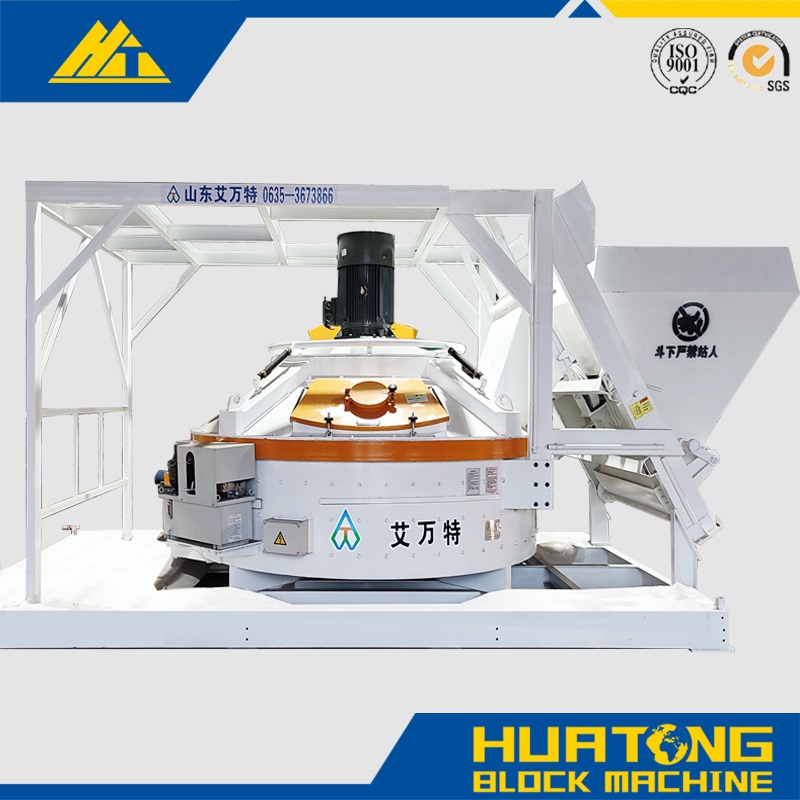

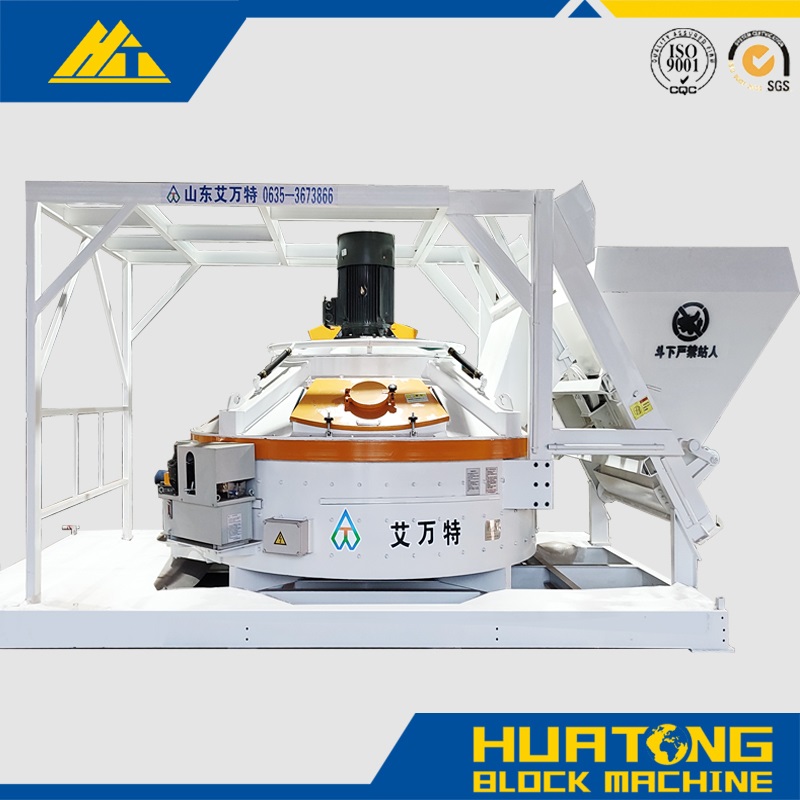

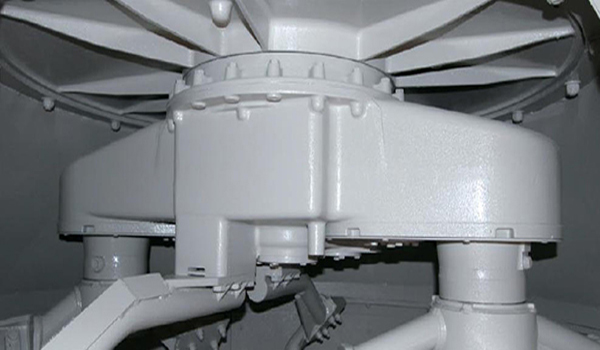

The planetary mixer employs asymmetrically designed mixing arms that effectively eliminate dead zones during high-speed operation, significantly enhancing mixing efficiency | |

The drive system integrates a high-performance Siemens motor with a custom-engineered reducer from a renowned industrial group. This premium configuration ensures robust load-bearing capacity while delivering superior operational advantages including high torque output, reduced acoustic levels, and optimized energy efficiency. | |

The mixing arm operates through a dual-axis motion system, combining rotation about its own axis with revolution around the central shaft. This compound movement generates intricate, overlapping material paths that systematically eliminate dead zones and ensure complete mixing efficiency | |

The wear-resistant liners are constructed from premium NM500 steel or high-chromium alloy cast iron (KMTBCr15Mo2-GT). Each component features permanent identification marking, enabling maintenance teams to directly reference and procure exact replacements through streamlined ordering procedures. | |

The water atomization system employs a hexagonal array of diagonally-oriented nozzles to achieve comprehensive coverage and optimal humidity distribution throughout the mixing chamber. | |

The hydraulic power unit features proprietary engineering, incorporating industrial-grade hydraulic cylinders with integrated buffering technology to ensure exceptionally smooth and reliable door cycle operations |

Equipment application scenarios

Shipping and Logistics

From outbound inspection to loading and securing, every step is strictly controlled to ensure that the equipment/cargo arrives intact. Subsequent logistics information will be synchronized immediately. If you have any questions, please feel free to contact us. We will escort you from beginning to end!