Concrete Block Machine

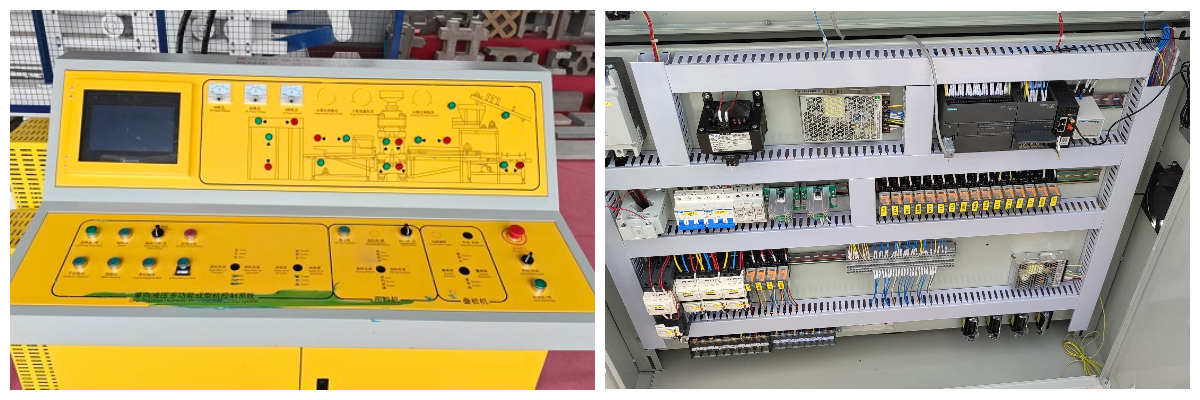

1,The vibration adopts Principle of Resonant Centrifugal Force and it can be directional vibration.

2,The Mould is made with heat treatments of quenching,tempering,carbonization and boriding.Working life of mould is improved.

3,The hydraulic system adopts Proportion Direction Valve.

4,The vibration system adopts German Frequency Conversion Technique.The vibration motor is Frequency Conversion Controlled.The lubrication of Vibrator adopts oil immersed,which improve the using life of Bearing and Gear of vibrator.

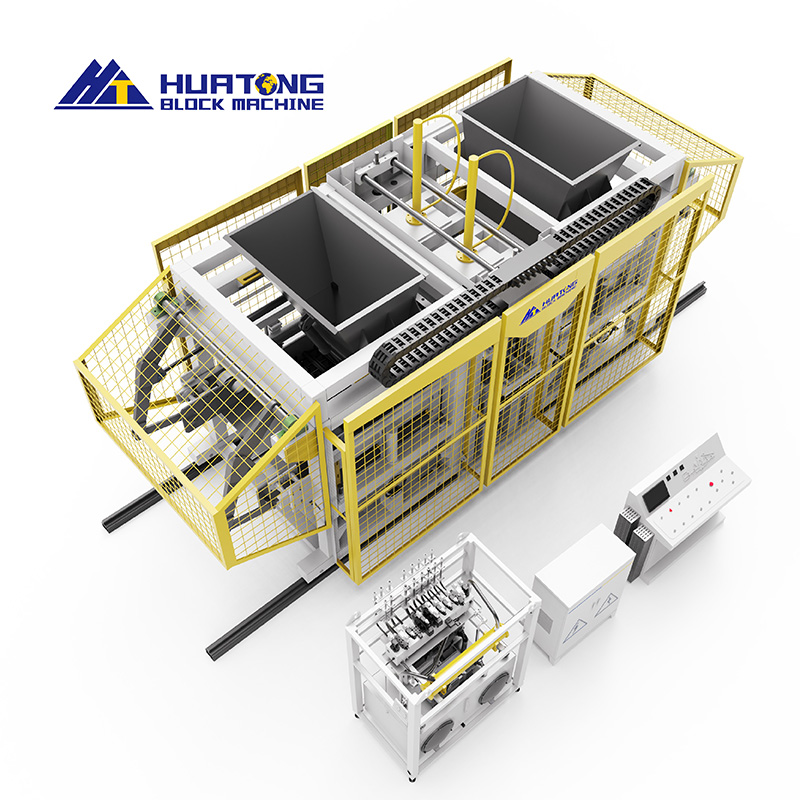

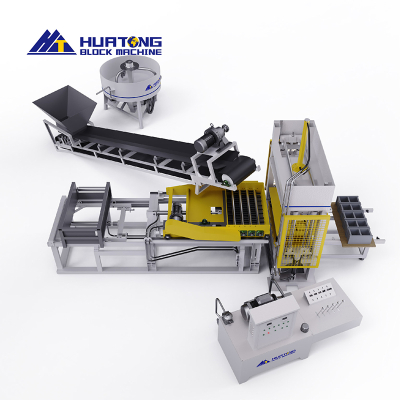

The full-automatic Concrete Block Machine is the 1 kind of mechanical equipment that completes the whole process of raw material mixing, pressing molding, automatic demoulding, conveying and maintenance through an automatic system to realize efficient and standardized production of bricks. The concrete block machine core advantage is to greatly reduce manual intervention and improve production efficiency.

Concrete Block Machine Technical Parameters:

| Dimension | 4170*2650*3260mm |

| Mode of Vibration | Table Vibration |

| Pallet Size | 1350*1150*25-40mm |

| Rated Pressure | 21Mpa |

| Oil Station Power | 22KW |

| Cycle Time | 15-20'S |

| Mould Rockwell Hardness(HRC) | ≥55 |

| Application Category | Construction industry: production of concrete hollow blocks, solid bricks, etc. |

| Raw Material | Cement, sand and gravel, stone powder, stone nitrate, slag, slag and other building materials |

Production Capacity of QT15-15 Concrete Block Machine:

| Block Type | Picture | Size(L x W x H) | Pcs./Pallet | Cycle Time | Pcs./8 Hours |

| Hollow Block |  | 400x200x200mm | 15 | 15-20's | 21600-28800 |

| Hollow Block |  | 400x150x200mm | 18 | 15-20's | 25900-34500 |

| Hollow Block |  | 400x100x200mm | 24 | 15-20's | 34500-46000 |

| Paving Block |  | 200x100x60mm | 54 | 20-25's | 62200-77700 |

| Paving Block |  | 225x112.5x60mm | 35 | 20-25's | 40300-50400 |

Concrete Block Machine Main performance characteristics:

1,Sophisticated design: the balance system adopts the 4 rod guide method, and the ultra-long guide sleeve ensures the precise movement of the pressure head and the mold box. The rack adjustment system improves the balance and coordination between the pressure head and the mold box in the production process. Rotary convection and compulsory cloth mode ensure the density of bricks, shorten the cloth time, and the gear transmission mode is more stable. The walking style of the double-bar crank arm increases the speed of the fabric, showing durability and stability. The frequency conversion technology of the stacking machine has the advantages of speed control, intelligent adjustment of the speed of the cycle, smooth starting, speed coordination, and flexible operation.

We got ISO9001 certificate and some China third party certificate,obtained many Chinese invention patents:

Best Service:

1,Provide plant layout plans and equipment foundation drawings in advance. If necessary, arrange on-site guidance on infrastructure, water, and electricity.

2,. Provide technical consultation, assist in establishing a management framework and train production management personnel.

3,. Arrange technicians to provide on-site installation guidance and train production operators.Establish processes, and subcontract responsibilities. From quality control and cost control, employee assessments to subcontracting, safety production, equipment maintenance, procurement, and marketing, we aim to help customers enter the industry quickly and achieve profitability.

Concrete Block Machine Customer Work Site:

After-sale Service:

1.We establish customer profile which documents model, configuration, and special requirements.It allowe us to provide the services they need more accurately and promptly.

2. We offer telephone support. After confirming your service request, Huatong after sales technicians will assist you by phone in locating the fault and proposing a solution.

3. We offer an on-site troubleshooting guarantee. If a device issue cannot be resolved by phone, Huatong will immediately dispatch a technician to address it.

4. Huatong provides lifetime maintenance for its machine with regular on-site visits by technicians to ensure the equipment remains in good working condition.