Block Machine

Model: QT5-15

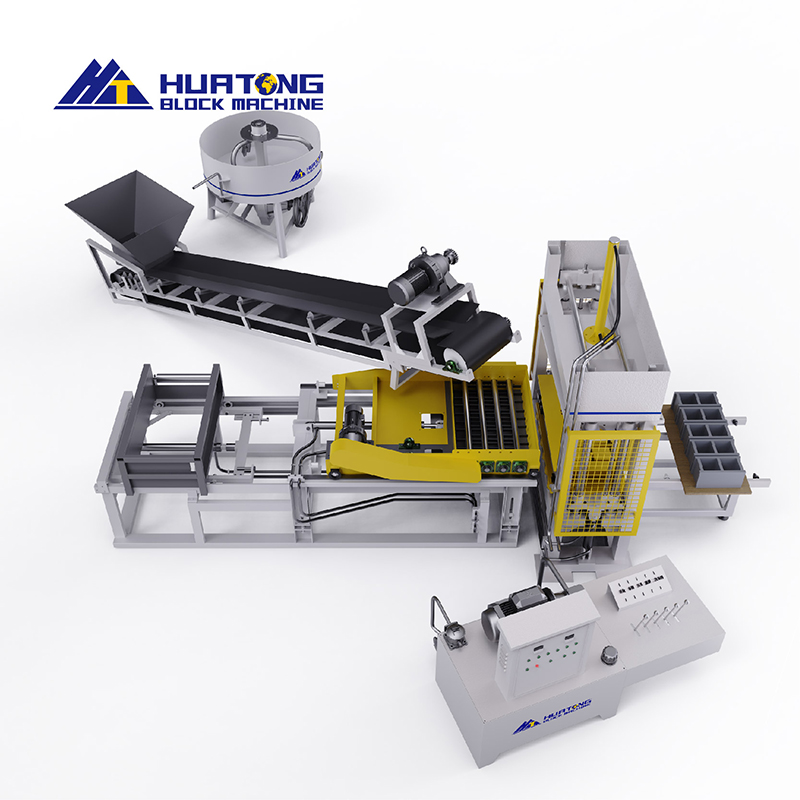

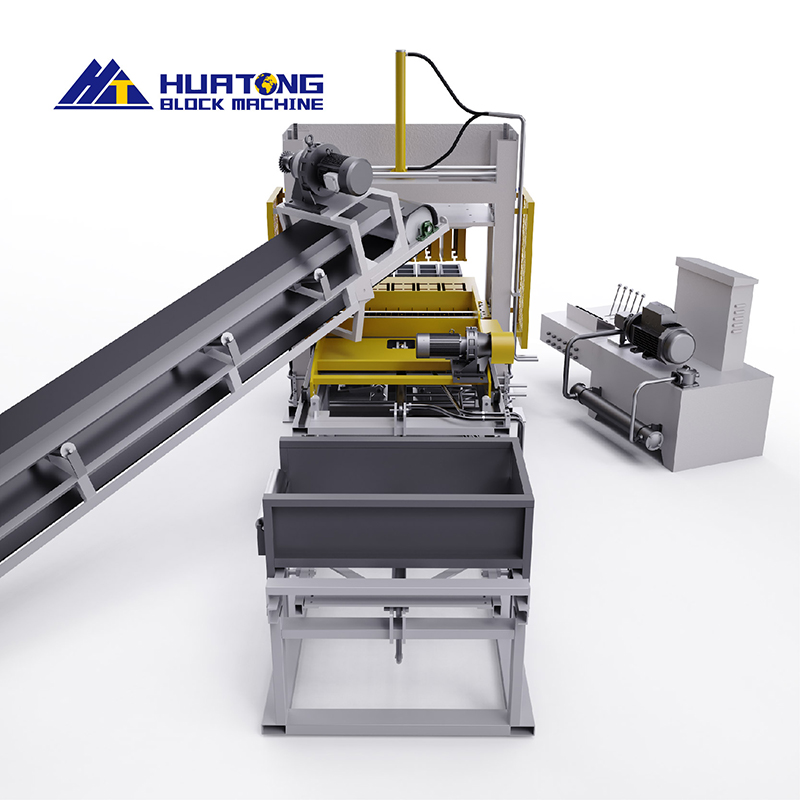

Our factory specializes in manufacturing block making machines. These machines use cement concrete as raw material to produce bricks. They utilize an enclosed belt conveyor and strictly control the semi-storage capacity of small materials to ensure they are readily available for delivery and use. This prevents premature liquefaction of the concrete due to aftershocks and ensures the strength of the block making machine.

The concrete brick making machine is a China Standard model, meaning it is manufactured in strict accordance with standard production techniques and processes. This multifunctional machine is capable of mass-producing standard concrete products such as curbstones, kerbs, and solid bricks. Its compact overall structure and rational layout utilize mechanized rotating components for high precision and reliability, reducing labor intensity and improving production efficiency. Upper and lower pressure, directional vibration, and variable frequency braking ensure high-density and high-strength forming.

Technical Parameters of QT5-15 Semi-Automatic Block Making Machine

| Item | Specification |

Overall Dimensions | 3000×1900×2930mm |

Forming Method | Table vibration |

Pallet Size | 1150×580×25–40mm |

Rated Pressure | 21 MPa |

Hydraulic Station Power | 7.5 kW |

Forming Cycle | 15–20 seconds/time |

Mold Hardness (Rockwell) | ≥55 HRC |

Application Categories | Construction Industry: For producing concrete hollow blocks, solid bricks, etc. |

Raw Materials | Cement, sand, stone chips, stone powder, slag, and other construction materials |

QT5-15 Semi-Automatic Block Making Machine Output Reference Table

| Product | Image | Size (mm) | Blocks per Mold | Forming Cycle | Daily Output (10 hours) |

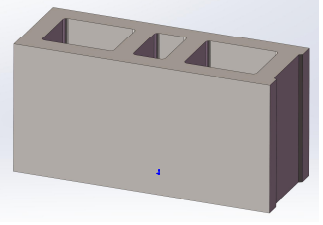

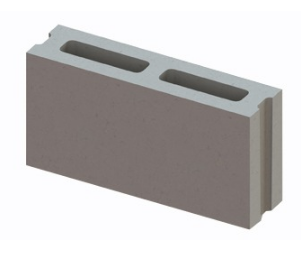

Hollow Block |  | 400×200×200 | 5 pcs | 20–25 s | 7200–9000 pcs |

Hollow Block |  | 400×150×200 | 6 pcs | 20–25 s | 8640–10800 pcs |

Hollow Block |  | 400×100×200 | 9 pcs | 20–25 s | 12960–16200 pcs |

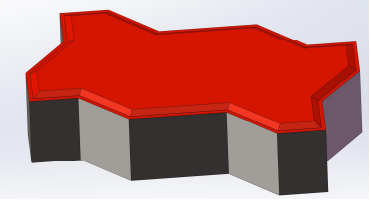

Paving Brick |  | 200×100×60 | 20 pcs | 25–30 s | 24000–28800 pcs |

Paving Brick |  | 225×112.5×60 | 16 pcs | 25–30 s | 19200–23040 pcs |

Standard production certification

Product delivery guarantee

FAQ

What precautions should be taken when operating a hydraulic oil station? Answer: Check the oil temperature while the equipment is operating. If the oil temperature is too high, check the cooling system for malfunctions to prevent high oil temperatures from affecting equipment performance.

How can the density of the finished bricks be controlled? Answer: The vibration forming time of the unfired brick machine should be strictly controlled and adjusted according to the brick shape and density. If the raw materials or brick shape change, the feed rate or number of times the bricks are placed can be adjusted to improve the quality of the formed bricks.