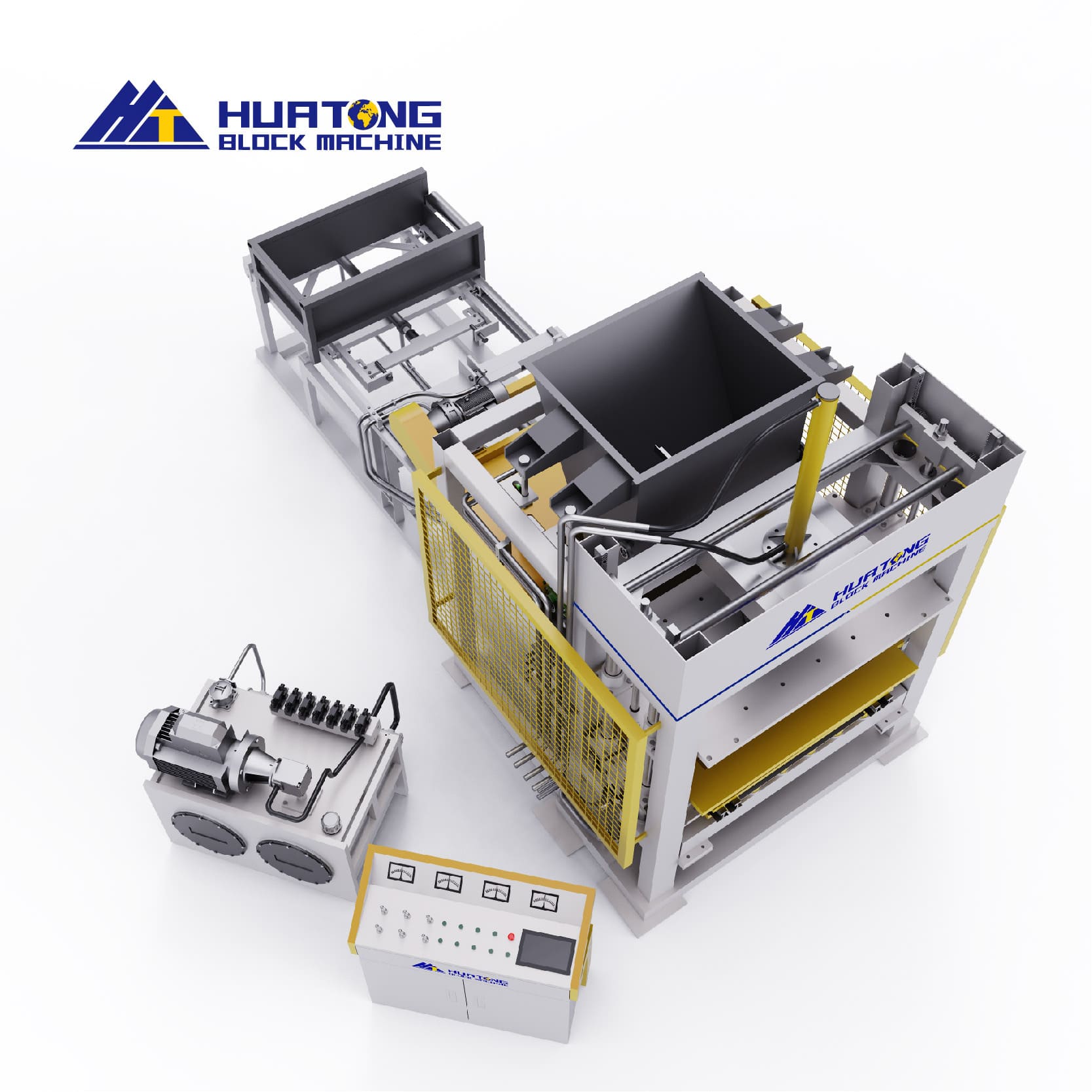

Brick Making Machine

Model: QT5-15

This fully automatic brick making machine is independently developed and features intelligent, highly automated features. It fully utilizes cutting-edge technologies such as digitalization and information systems, and is widely used in new urbanization and sponge city construction.

The core advantages of the QT5-15 brick making machine can be summarized as follows:

Product: It produces high-quality building materials with high strength, high density, and an attractive appearance.

Product: It offers stable production capabilities with high output, high automation, and low failure rates.

Investment: It achieves the comprehensive economic benefits of multi-purpose use, energy conservation, waste reduction, and reduced labor costs.

Long-term: Its durability and reliable core components ensure the long-term investment value of the equipment.

Thus, the QT5-15 is a mature product that strikes an excellent balance between performance, efficiency, reliability, and affordability, making it a top choice for investment in the block production industry. When choosing a machine, it is recommended to visit the manufacturer to observe actual production and learn more about its after-sales service policies.

Production Capacity of QT5-15Automatic Block Making Machine

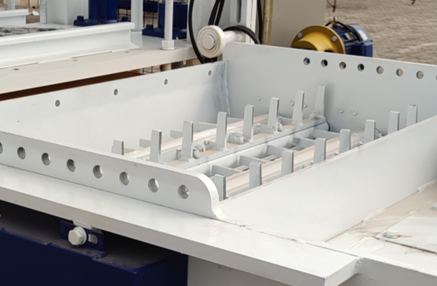

Block Type | Picture | Size(L×W×H) | Pcs./ Pallet | Pcs./ Hour | Pcs./ 8Hours |

Hollow Block | 400x200x200mm | 5 | 1500 | 12000 | |

Hollow Block | 400x150x200mm | 6 | 1080 | 8700 | |

Hourdi Block | 200x100x60mm | 20 | 2880 | 23040 | |

Hollow Block | 530x160x195mm | 16 | 2300 | 18400 | |

We produce mould according to size and shape of client’s block. | |||||

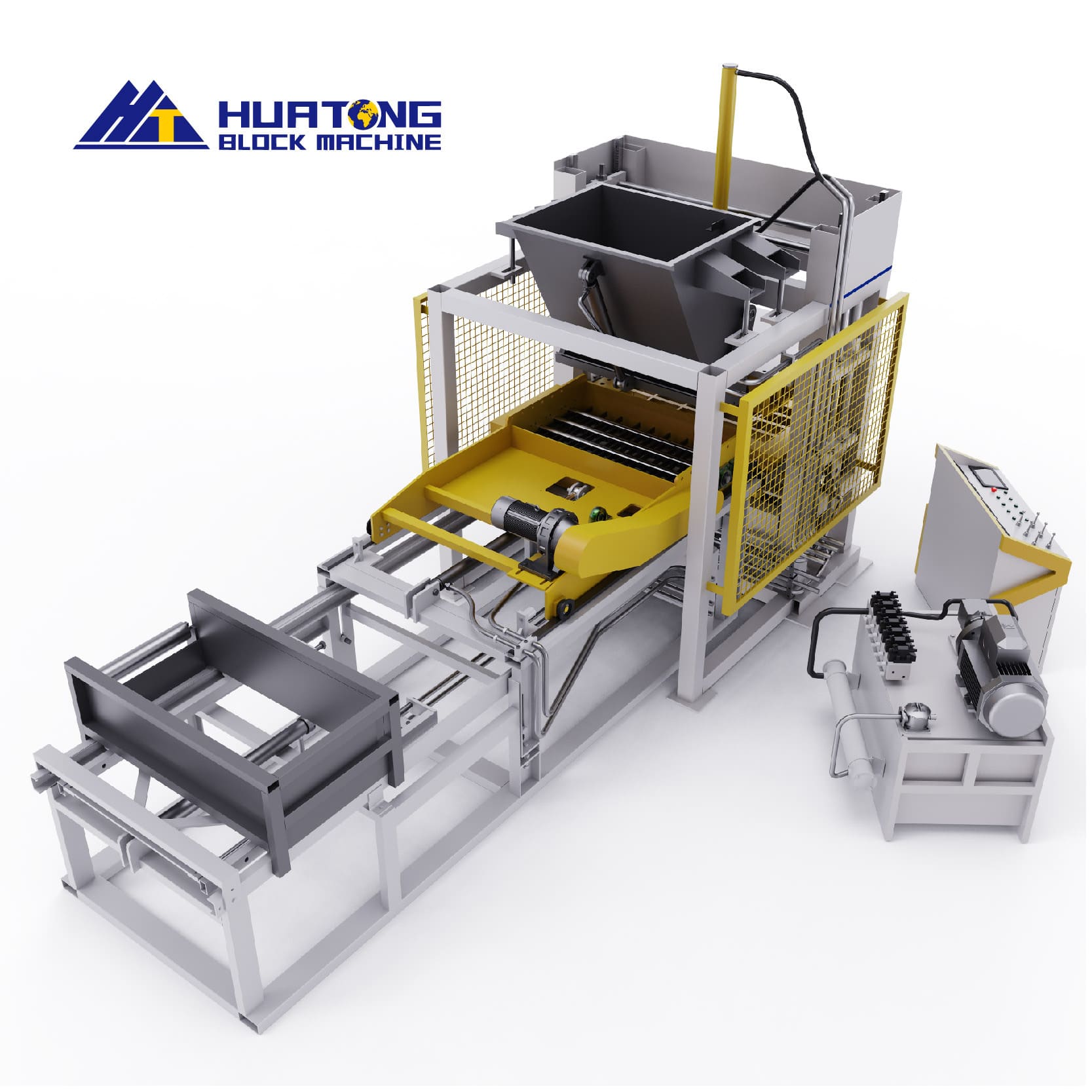

Technical Parameter of QT5-15Automatic Block Making Machine

Dimension | 3000×1900×2930mm |

Weight | 10000KGS |

Pallet Size | 1150×580mm |

Power | 35.7KW |

Mode of Vibration | Table Vibration |

Vibration Frequency | 4200r/min |

Vibration Force | 75KN |

Cycle Time | 12S |

Product Advantages

Vibration motor | |

Fabric cart | |

Vibration table The characteristic of the harmonic vibration principle is that the vibrating element, vibrating table, mold frame, and concrete mixture undergo primary harmonic oscillations at specific frequencies and amplitudes. At this time, pulses apply pressure to the concrete mixture in the mold. As a result, under the action of vibration and the falling pulses, the mixture is compacted. | |

Fabric cart self-adjustment |

![切片.gif]()

Real photos of brick product

Company Qualifications

Shipping and Logistics

1. What are the features of this equipment? Answer: It supports multi-purpose use and features an intelligent electronic control interface, saving labor and adapting to different brick types and production requirements.

2. What does on-site customer safety training include? Answer: Safety operating procedures focus on pre-job training, wearing protective equipment, prohibiting touching moving parts, equipment inspection, and powering off during maintenance.