Cement Automatic Block Machine

Cement automatic block machine have better production efficiency. As a fully automatic closed-loop production line, it greatly reduces labor. Through real-time optimization and scheduling of each link of the production process, cement automatic block machinereduces waiting time, greatly improves production efficiency and meets production requirements.

Intelligent and simple operation using computer control, man-machine interface, simple operation, generally only simple training can be operated. It has a fault self-diagnosis system to facilitate troubleshooting. Ensure the quality of products

QT18-15 full-automatic cement automatic block machine as a closed-loop production line,cement automatic block machine is mainly composed of batching system, mixing system, main machine brick making system, automatic maintenance system, palletizing and packing system and pallet return system. It has the advantages of high degree of automation, no need for manual feeding, transportation, low labor intensity, good molding effect, replaceable wearing parts, saving mold maintenance cost, wide range of applicable materials.

Comprehensively speaking, the QT18-15 fully automatic production line performs exceptionally well in energy efficiency and stability. It is capable of producing a variety of concrete products and is suitable for users with a certain scale of production capacity.

Here are the main advantages of the QT18-15 cement automatic block machine production line for your quick reference:

1. Enhanced Production Efficiency

As a fully automated closed-loop production system, it requires minimal manual intervention. Through real-time optimization and scheduling of each production stage, it significantly reduces idle time and substantially increases output efficiency to meet production demands.

2. Smart and User-Friendly Operation

Equipped with computer control and human-machine interfaces, the system is simple to operate and typically requires only basic training. Its integrated self-diagnostic functionality facilitates quick troubleshooting while ensuring consistent product quality.

3. Reliable and Durable Performance

Constructed with high-strength steel and specialized welding techniques, the framework ensures exceptional robustness. The air cushion and double-liner shock absorption systems effectively minimize vibration impact on the equipment, extending service life. The powerful main vibration system produces high-density products with superior strength and dimensional accuracy.

4. Adaptability and Flexibility

Capable of manufacturing various concrete products including multiple types of blocks, bricks, and paving stones. The specially designed mold configuration enables relatively quick and convenient mold changes.

Block sample for reference:Advantages of cement automatic block machine:

1,Excellent mechanical design: reference unique design, using super steel, processed by special welding technology. According to the principle of resonance centrifugal force, the excitation table uses directional vibration to make it run reliably, and has the advantages of convenient installation and maintenance;

2, Cement automatic block machine body adopts a closed structure to prevent dust pollution.

3,Cement automatic block machine mold adopts a variety of heat treatment processes such as quenching, tempering, carburizing, and nitriding, which greatly enhances the wear resistance of the mold, thereby increasing the life of the mold, far exceeding the national standard.

4,The balance system adopts the 4 rod guide mode, with the long guide sleeve to ensure the precise movement of the pressure head and the mold box. The rack adjustment system improves the balance and coordination between the pressure head and the mold box in the production process. Rotary convection, mandatory concrete feed way, to ensure the product compactness, shorten the feed time, gear transmission mode is more stable. Double cylinder arm walking way, feeding faster and more stable.

5,The automatic stacking machine has the advantages of intelligent adjustment cycle speed, smooth starting, fast and slow speed coordination, and flexible operation.

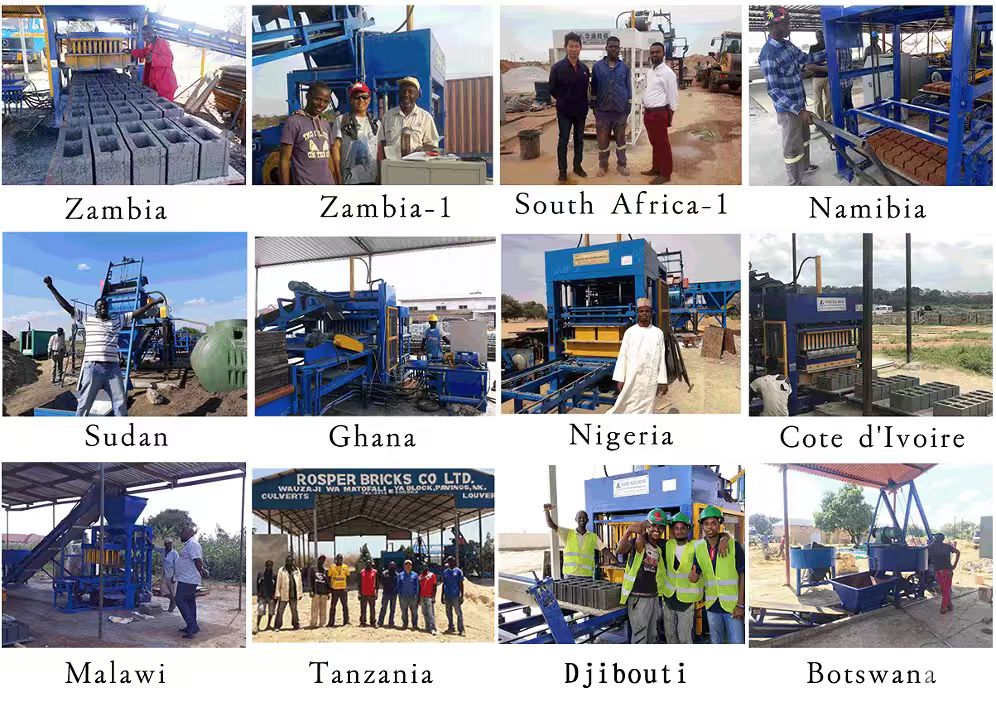

Some customer worksite:

QT18-15 type cement automatic block machine is the one large-scale and efficient concrete block production equipment. It adopts advanced four-axis vibration technology to make the product form in a short time with high compactness. Its large output, stable performance, high degree of automation, is the first choice for one large equipment.

Welcome to visit our company.