Automatic Block Production Line

Intelligent Automation: Fully automated control from material feeding to finished brick output ensures stable quality, high precision, and reduced labor intensity.

Modular Customization: Flexible modular design with reserved interfaces allows personalized configuration to meet diverse production needs.

Energy-Saving & Reliable: Equipped with Siemens PLCs and Danfoss inverters for stable operation, low noise, and high energy efficiency.

Integrated Smart System: Combines forming, curing, and palletizing in one seamless process, improving productivity and cutting operational costs.

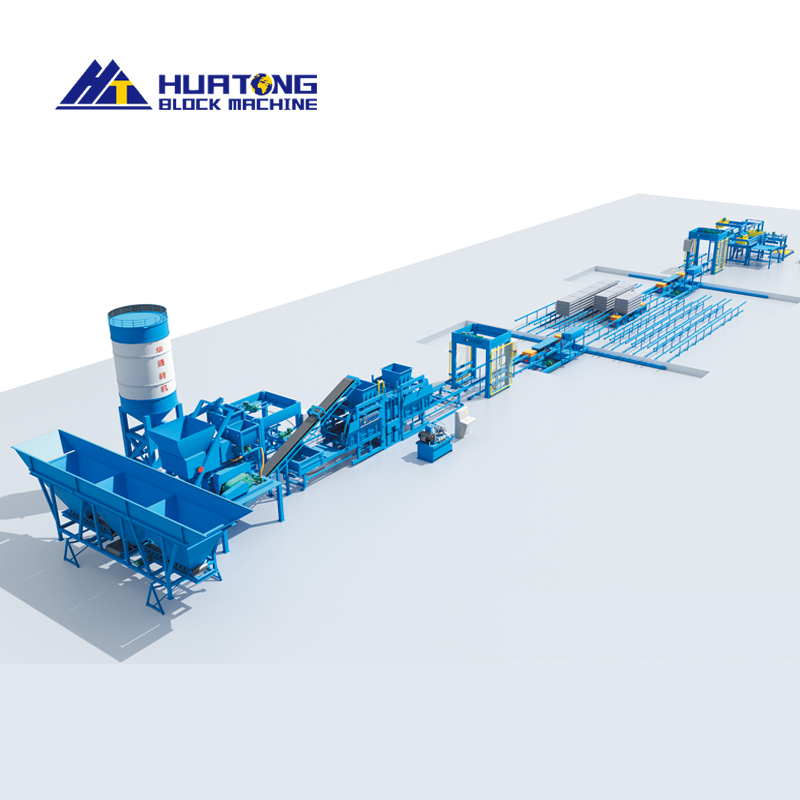

Huatong Fully Automatic Intelligent Integrated Brick Production Line

The Huatong Fully Automatic Intelligent Integrated Brick Production Line is independently developed and manufactured by Huatong Machinery. It incorporates a large number of proprietary core technologies, featuring an elegant overall layout and a smooth, efficient process flow. Practical operation has proven the system to be well-configured, reliable, and efficient.

This equipment adopts a modular design, fully considering users’ desire to participate in the product design process. Adequate space and interfaces are reserved to meet users’ customized needs, providing personalized solutions based on a universal and reliable platform.

The production line mainly consists of four core parts:

Fully Automatic Intelligent Non-Burning Brick Machine Production Line

Wireless Fully Automatic Curing System

Fully Automatic Brick-Board Separation System

Central Control System

(1) Fully Automatic Intelligent Non-Burning Brick Machine Production Line

This production line realizes complete one-line automatic control. Operators only need to load raw materials into the batching silo with a loader, and the system will automatically complete the entire production process — including batching, mixing, water addition, cement feeding, material discharging, brick forming, and brick output.

It achieves full automation, reduces labor intensity, and ensures greater product consistency, quality, and output stability.

(2) Wireless Fully Automatic Curing System

Independently developed and designed by Huatong, this highly intelligent curing system consists of two mother cars and four sub cars. It replaces manual forklift operations for brick handling.

When the finished bricks exit the brick machine, the sub car automatically moves under the waiting rack, lifts the finished bricks, and transfers them onto the mother car. The mother car, following pre-programmed instructions, transports the sub car carrying the bricks to the curing kiln entrance. The sub car automatically enters the kiln for curing, while the mother car proceeds to the next kiln entrance to retrieve another sub car, achieving continuous, non-stop operation.

After curing is completed, the sub car automatically transfers the cured bricks onto the mother car located at the opposite end, thereby realizing fully automatic kiln entry and exit.

This system significantly reduces labor and operational costs while improving productivity and efficiency.

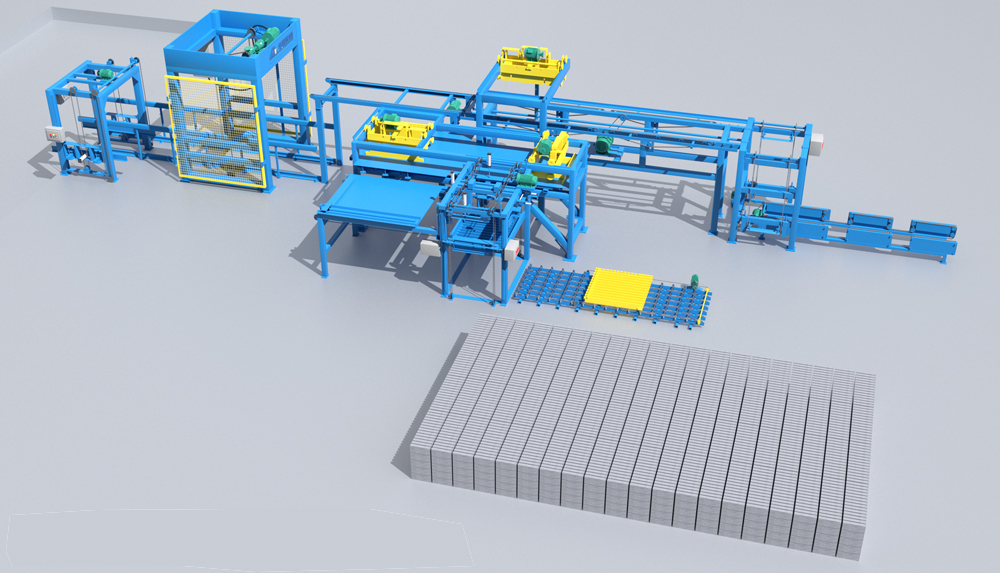

(3) Huatong Intelligent Brick-Board Separation System

The Huatong Intelligent Brick-Board Separation System adopts a reserved-gap palletizing method, designed as an intelligent brick stacking system to eliminate manual handling.

It solves issues such as high labor intensity and low production efficiency, enabling mechanized loading and unloading of finished bricks.

The system is installed near the curing yard to allow on-site palletizing of cured products. It can also be integrated with the brick production line and automatic curing system to achieve online palletizing.

The system consists of multiple modules, including:

Brick-Board Feeding Machine

Lifting System

Brick-Board Conveying System

Brick-Board Separation Unit

Automatic Rotating and Hole-Reservation System

Stacking Unit

Palletizing Conveying System

The entire system operates without bottom pallets, driven by electric and pneumatic power, with all electric drives featuring variable frequency control.

The PLC and touch display screen are from Siemens (Germany), and each gearbox is equipped with an independent inverter from Danfoss (Denmark), ensuring stable, low-noise, and energy-efficient performance.

Advantages of the Huatong Intelligent Brick-Board Separation System

Intelligent three-push palletizing system with rotation function — automatically reserves gaps for all brick types.

Increases production capacity with a high level of automation.

Saves labor and reduces operator workload.

Uses internationally renowned electrical components for stable, efficient, and low-noise performance.

Low energy consumption and small footprint.

Compatible with various brick machine models — different product types can be set simply by adjusting computer parameters.

Smart, adjustable palletizing dimensions for flexible operation.