Automatic Brick Machine

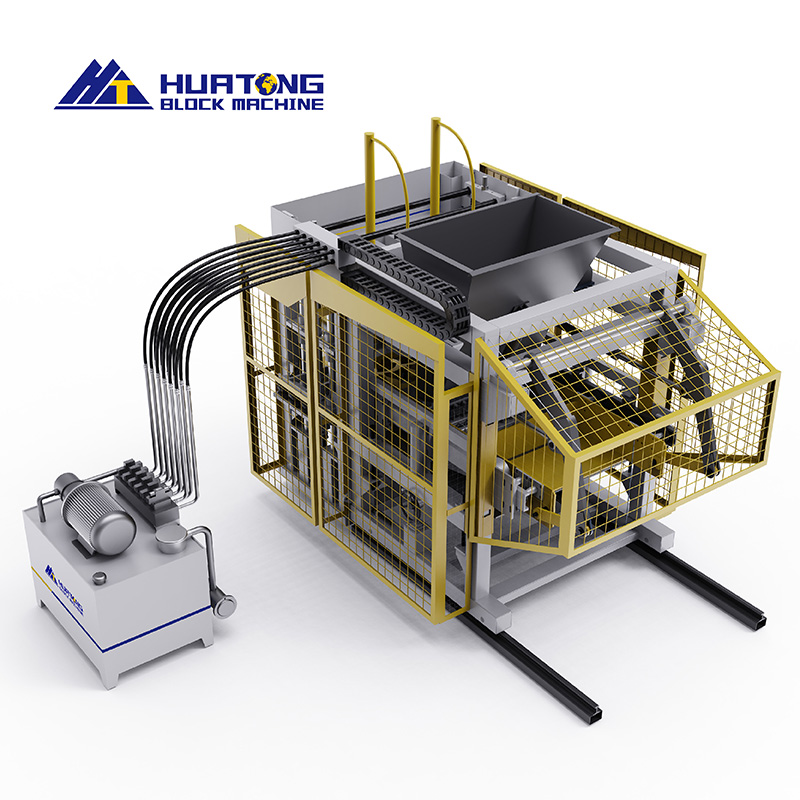

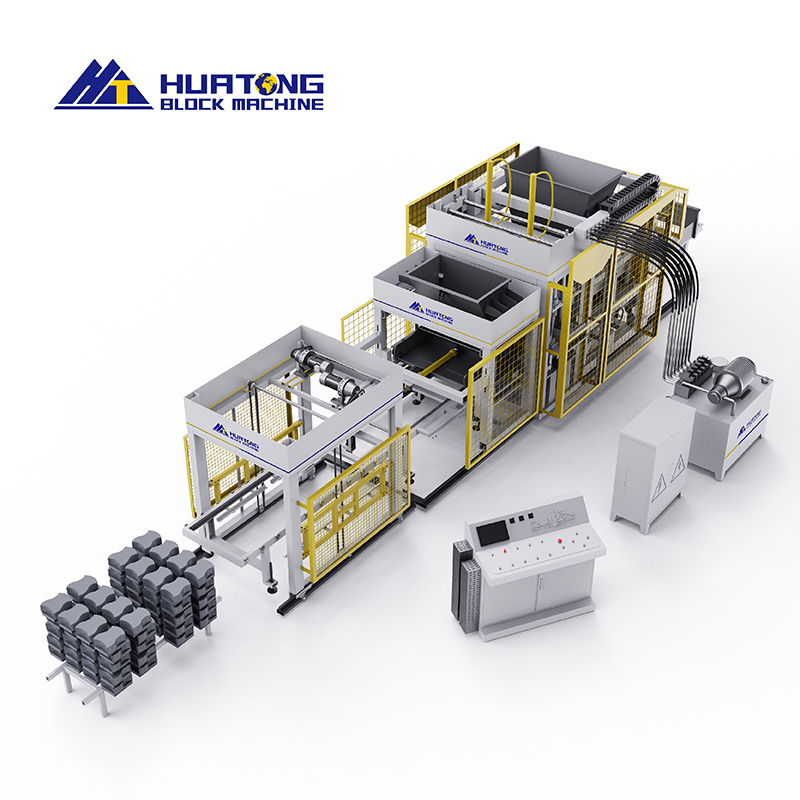

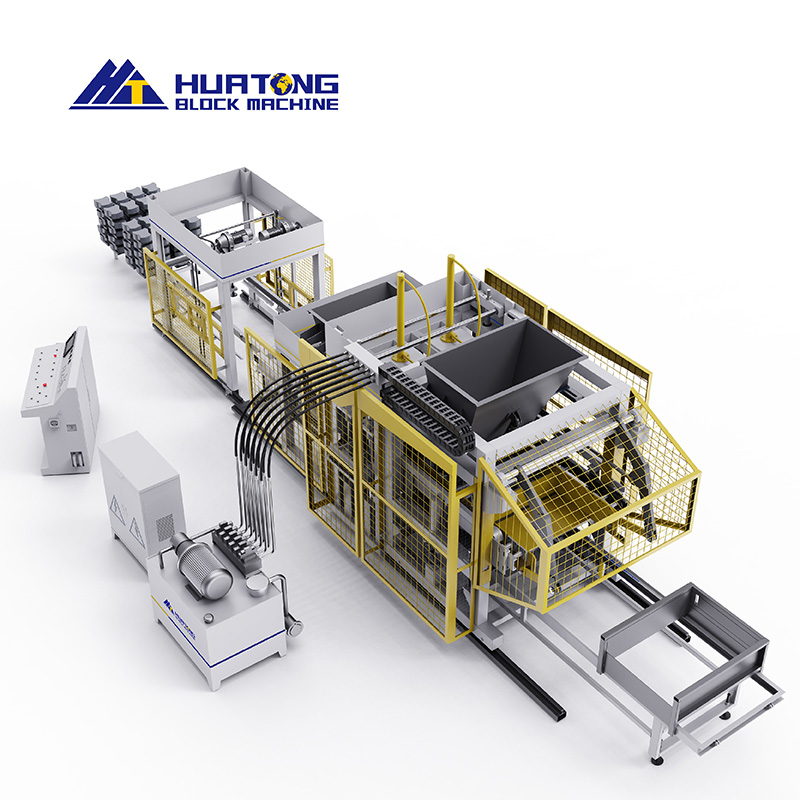

The QT12-15 Automatic Brick Machine adopts German frequency conversion technology and main machine frequency conversion control.

The exciter assembly adopts oil-immersed type, which improves the transportation speed and makes the concrete fully liquefied and exhausted instantly.

The life of the bearing is increased by more than 1 times. The synchronization and soft start function of the vibrator assembly 5 great advantages of improving the density of bricks, saving electricity and forming quickly.

Automatic Brick Machine Excellent mechanical design: Automatic Brick Machine reference unique design, using super steel, processed by special welding technology. According to the principle of resonance centrifugal force, the excitation table uses directional vibration to make it run reliably, and has the advantages of convenient installation and maintenance; Automatic Brick Machine body adopts a closed structure to prevent dust pollution. The mold adopts a variety of heat treatment processes such as quenching, tempering, carburizing, and nitriding, which greatly enhances the wear resistance of the mold, thereby increasing the life of the mold, far exceeding the national standard. The balance system adopts the 4 rod guide mode, with the long guide sleeve to ensure the precise movement of the pressure head and the mold box. The rack adjustment system improves the balance and coordination between the pressure head and the mold box in the production process. Rotary convection, mandatory cloth way, to ensure the product compactness, shorten the cloth time, gear transmission mode is more stable. Double cylinder arm walking way, cloth faster and more stable. The automatic stacking machine has the advantages of intelligent adjustment cycle speed, smooth starting, fast and slow speed coordination, and flexible operation.

Automatic Brick Machine Technical Parameters:

| Dimension | 4000×2400×3200mm |

| Mode of Vibration | Table Vibration |

| Pallet Size | 1350×900mm*25-40mm |

| Rated Pressure | 21Mpa |

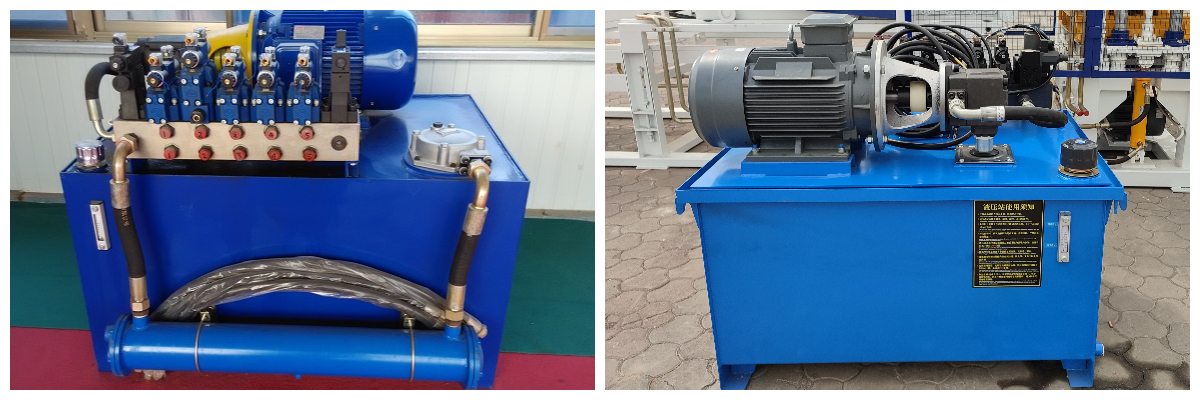

| Oil Station Power | 22KW |

| Cycle Time | 15-20S |

| Mould Rockwell Hardness(HRC) | ≥55 |

| Application Category | Construction industry: production of concrete hollow blocks, solid bricks, etc. |

| Raw Material | Cement, sand and gravel, stone powder, stone nitrate, slag, slag and other building materials |

Production Capacity of QT12-15 Automatic Brick Machine:

| Block Type | Picture | Size(L x W x H) | Pcs./Pallet | Cycle time | Pcs./8 Hours |

| Hollow Block |  | 400x200x200mm | 12 | 15-20's | 17280-23040 |

| Hollow Block |  | 400x150x200mm | 14 | 15-20's | 20160-26880 |

| Hollow Block |  | 400x100x200mm | 22 | 15-20's | 31680-42240 |

| Hourdi Block |  | 530x160x195mm | 9 | 15-20's | 11250 |

| Stock Brick |  | 220x105x70mm | 48 | 15-20's | 86400 |

| Paving Block |  | 200x100x60mm | 42 | 20-25's | 41470-51840 |

| Paving Block |  | 225x112.5x60mm | 30 | 20-25's | 34560-43200 |

Key features of Automatic Brick Machine:

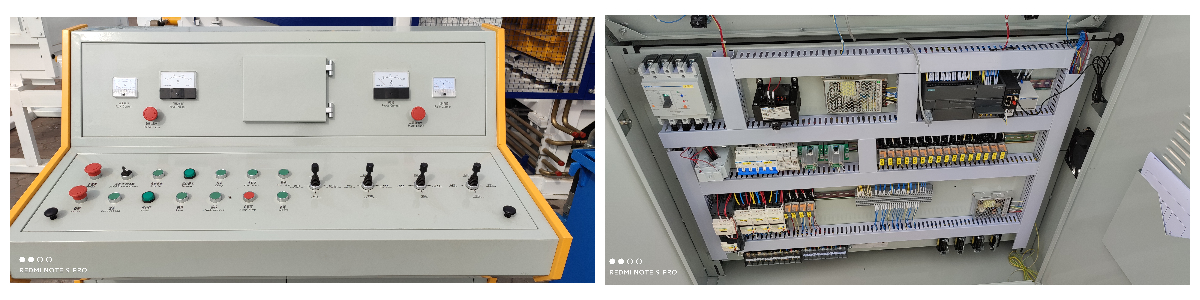

1,The use of excellent components: QT12-15 type automatic brick machine electrical and hydraulic systems are well-known brands, the main oil supply, electronic control components using Germany, Japan, Denmark and other imported components simple operation, stable performance.

A wide range of products: the installation of secondary cloth equipment, can also produce hollow blocks, curbstones, colored pavement bricks, grass-planting bricks, splitting blocks, and other products.

Superior performance: the vibration and pressure separation technology can completely isolate the interference of the resistance vibration and pressure, and the exciting force is strong, so that the material is rapidly formed, the cement is fully liquefied, and the product density is high.

Customer Worksite:

We have professional and technical personnel responsible for packaging and delivery to ensure that the products are delivered to the customers in good condition, the packing calculation is accurate, the cabinet space is not wasted, and the freight is saved for the customers.

Best Service:

Pre-sale service:

1. Accept customer inquiries, introduce our company's status and product categories.Guide customers in selecting suitable products based on local market demand.

2. Determine the scale of operations and guide customers in selecting equipment based on required production volume and investment budget.

3. Explain the production process, answer questions, and design a factory construction plan for customers.

4. Provide factory construction drawings, participate in construction supervision, and develop a feasible investment plan based on actual conditions.

5. Personalized services include comprehensive planning, reserved development space, smooth process flow, and minimized investment.

During sale service:

1. Review the contract, confirm or amend any unclear points or issues requiring negotiation.Track equipment production progress in real time to ensure on-time delivery.

2. Issue production instructions and schedule production as required.

3. Provide plant layout plans and equipment foundation drawings in advance. If necessary, arrange on-site guidance on infrastructure, water, and electricity.

4. Provide technical consultation, assist in establishing a management framework and train production management personnel.

5. Arrange technicians to provide on-site installation guidance and train production operators.Establish processes, and subcontract responsibilities. From quality control and cost control, employee assessments to subcontracting, safety production, equipment maintenance, procurement, and marketing, we aim to help customers enter the industry quickly and achieve profitability.

After Sale Service:

1. We establish customer profile which documents model, configuration, and special requirements.It allowe us to provide the services they need more accurately and promptly.

2. We offer telephone support. After confirming your service request, Huatong after sales technicians will assist you by phone in locating the fault and proposing a solution.

3. We offer an on-site troubleshooting guarantee. If a device issue cannot be resolved by phone, Huatong will immediately dispatch a technician to address it.

4. Huatong provides lifetime maintenance for its machine with regular on-site visits by technicians to ensure the equipment remains in good working condition.