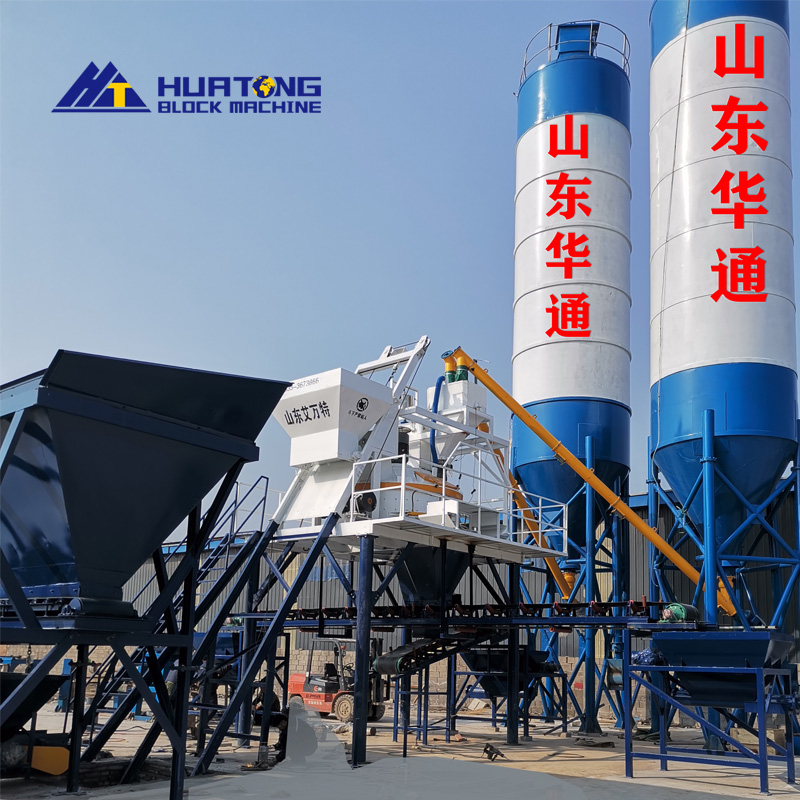

Ready Mixing Concrete Plant

Advantages of Ready Mix Concrete Plant: uniform mixing, small footprint, and wide applicability.

Efficient and uniform mixing: Multi-dimensional mixing ensures more thorough mixing of materials, shortens mixing cycles, and ensures consistent quality and less segregation in the finished concrete.

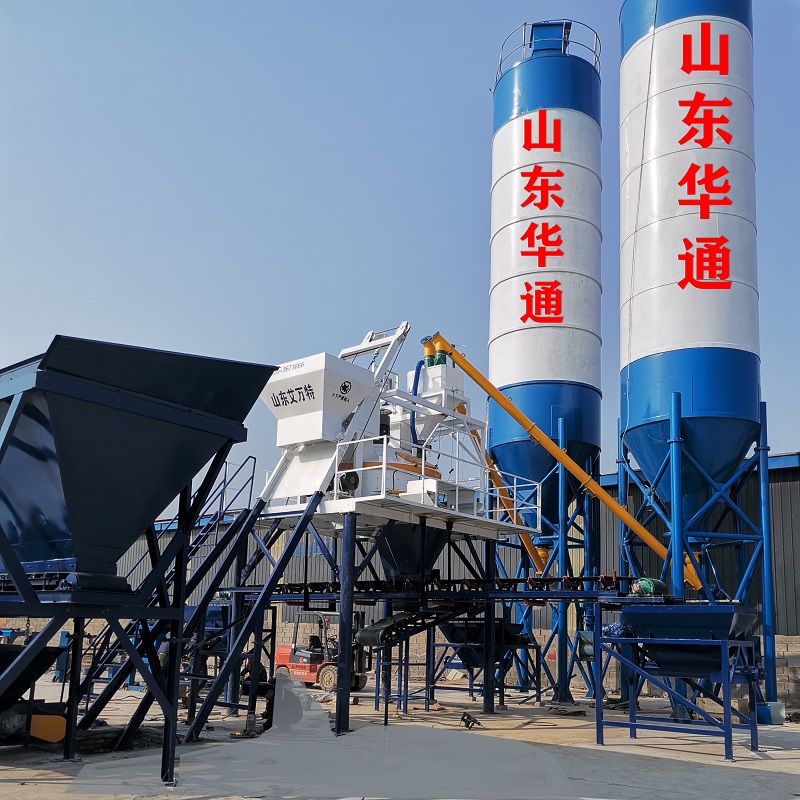

Space-saving and easy maintenance: The equipment features a compact structure, occupying approximately 30% less floor space than traditional batching plants of the same capacity. With fewer wearing parts, maintenance costs are low.

Widely applicable: Specialized in producing dry-hard, high-performance, and other specialty concretes, some models are also compatible with dry-mix mortar production.

HZN25 Ready Mix Concrete Plant

1.Highly efficient and consistent in quality: Utilizing a multi-dimensional mixing method, materials are mixed more evenly, preventing concrete segregation. When processing dry-hard, high-performance concrete, the mixing cycle is short, resulting in higher output per unit time and strong stability in finished product quality.

2.Small footprint and easy maintenance: The equipment has a compact structure, occupying approximately 30% less space than traditional batching plants of the same capacity, making it suitable for site-constrained environments. Fewer vulnerable parts, with some components reusable, lead to lower long-term maintenance costs.

3.Wide range of applications: Capable of producing special concrete for bridges and tunnels, meeting the homogeneous requirements of precast component plants, and compatible with dry-mix mortar production, it also caters to various scenarios such as cement products and prefabricated buildings.

4.Energy-efficient, intelligent, and cost-effective: Optimized transmission system design reduces energy consumption, and the automated control system allows for precise parameter control. Convenient operation and low replacement costs result in long-term cost savings, making it an outstanding value proposition.

5.Easier residual material removal: Some models are equipped with a reversible mixing drum or automatic scraping device, which effectively scrapes away residual concrete from the drum wall, reducing the need for manual cleaning, preventing residual material from solidifying and affecting subsequent mixing quality, and reducing the intensity of cleaning work.

6.Strong adaptability to aggregates: This unit can stably handle aggregates with slightly larger particle sizes or complex gradations. For example, when mixing concrete containing crushed stone and pebbles, it is less likely to cause material jamming or uneven mixing, minimizing production interruptions caused by aggregate characteristics.

7.Shorter commissioning cycle: The equipment's highly modular design allows for prefabrication of core components, streamlining on-site installation. This reduces installation and commissioning time by approximately 30% compared to traditional concrete mixing plants, enabling rapid commissioning and meeting urgent project start-up needs.

Choosing a vertical shaft concrete mixing plant means choosing the dual advantages of "cost reduction and efficiency improvement + quality assurance".