Concrete Mixing Plant

Model: HZN25 Concrete Mixing Plant is a complete

Advantages

1. It is suitable for small and medium-sized construction projects and commercial concrete production, such as hydropower projects, airports, highways, bridges, buildings, and pipe piles, cement pipes, and brick machines.

2. It utilizes a vertical-shaft planetary mixer, offering excellent mixing quality, short mixing cycles, and high efficiency. The control system is simple to operate, stable, and reliable, and features multiple functions, including re-weighing, de-weighing, continuous production, and intelligent alarms.

Concrete Mixing Plant Introduction

The concrete batching plant uses an MPG1000 vertical-shaft planetary mixer as the main unit and a PLD1600 batching machine as the batching machine. It is commonly used in large and medium-sized water conservancy, power, and bridge projects with small concrete volumes, long construction periods, and concentrated construction sites.

Features:

Eco-Friendly Material Handling

Non-stick hopper design enables rapid discharge, while fully enclosed loading prevents particulate emissions.

Centralized Dust Control

Integrated negative-pressure pulse-jet filtration with central monitoring ensures compliant dust management.

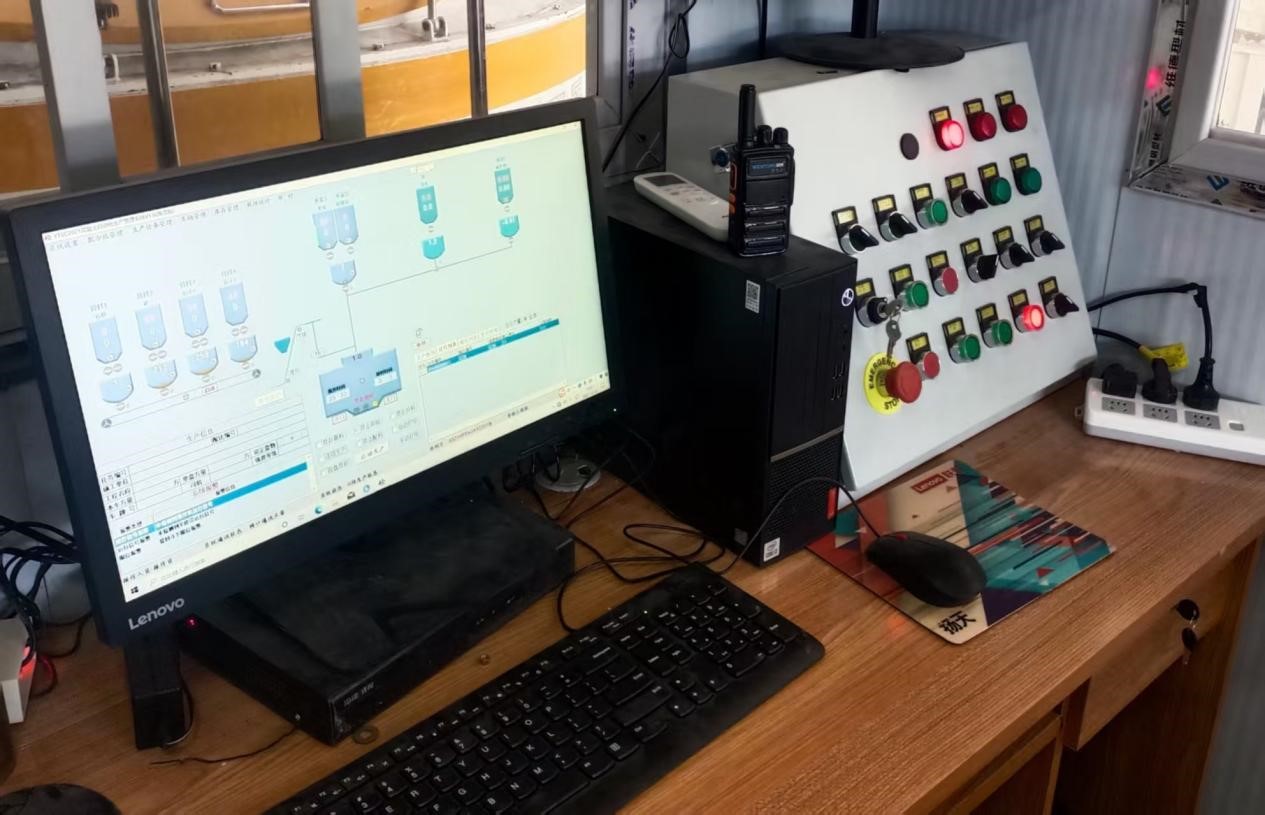

Automated Process Control

Reliable operating system with batch correction, weight compensation, continuous production, and smart diagnostics.

Avant concrete mixing station consists of four main components

1. Vertical planetary mixer, platform, and lifting system (with belt loading and bucket loading).

2. Batching machine: two types: cumulative metering and separate metering

3. Metering system: including water metering, cement metering, and admixture metering

4. Control system: divided into two types: full computer automatic control and touch screen automatic control

Mixing plant model | HZN25 |

Host model | MPG500 |

Batching machine model | PLD800 |

Theoretical production efficiency (m³/h) | 25 |