Cement Mixer Machines

Model:The HZN35 Cement Mixer Machines

Advantage:

Primary Application Scope

1.This equipment is engineered for mid-scale construction initiatives and commercial concrete production, with proven efficacy in critical infrastructure projects including hydropower facilities, aviation hubs, transportation networks, and structural engineering systems. It further demonstrates versatile adaptation for prefabricated component manufacturing encompassing concrete piles, pressure pipes, and automated masonry production lines.

2. Various designs and installation options are available to meet user needs.

Cement Mixer Machines Introduction

The concrete batching plant uses an MPG1000 vertical-shaft planetary mixer as the main unit and a PLD1600 batching machine as the batching machine. It is commonly used in large and medium-sized water conservancy, power, and bridge projects with small concrete volumes, long construction periods, and concentrated construction sites.

Features:

1. The vertical planetary mixer eliminates manual cleaning and prevents sticking to the mixer shaft and drum cover.

2. The concrete receiving hopper utilizes wear-resistant design for durability, extending its service life by more than five times that of previous models without damaging the hopper.

Avant concrete mixing station consists of four main components:

1. Vertical planetary mixer, platform, and lifting system (with belt loading and bucket loading).

2. Batching machine: two types: cumulative metering and separate metering

3. Metering system: including water metering, cement metering, and admixture metering

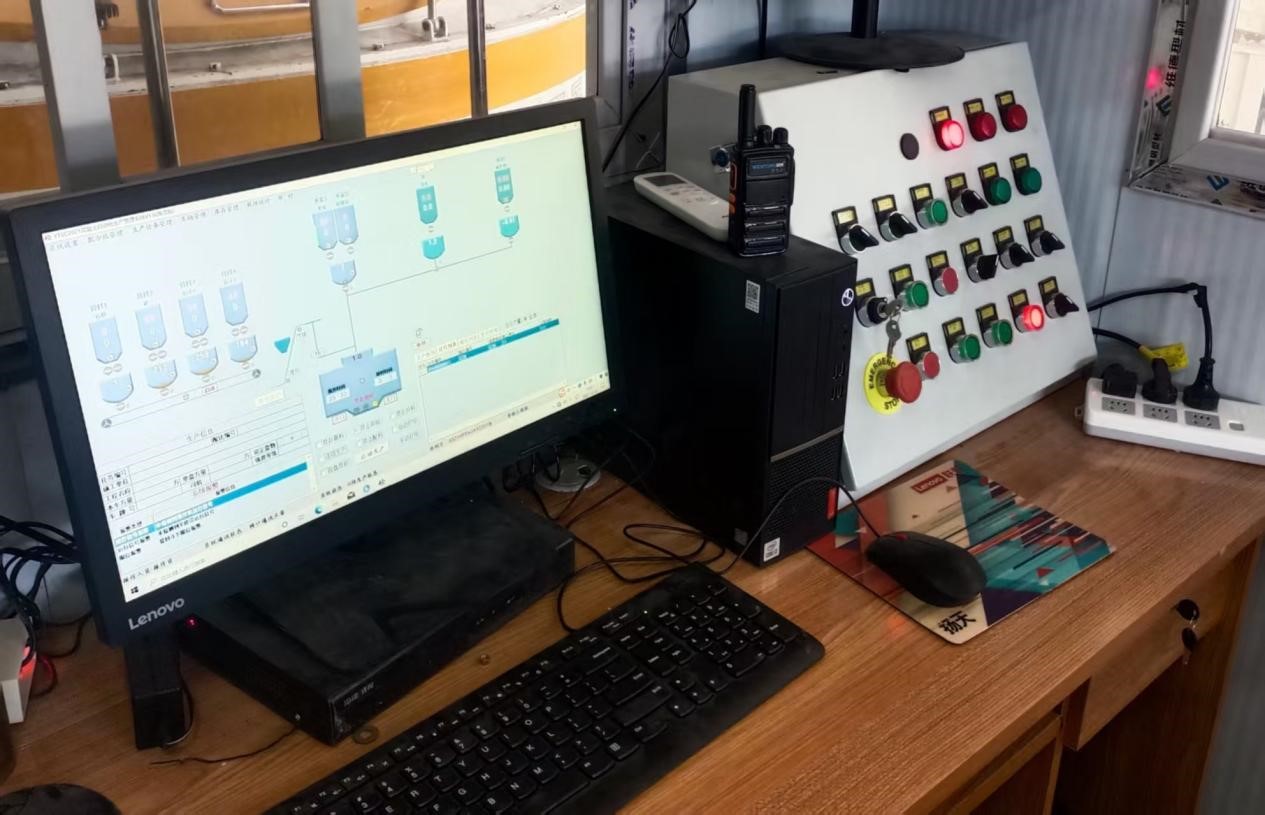

4. Control system: divided into two types: full computer automatic control and touch screen automatic control

Mixing plant model | HZN35 |

Host model | MPG750 |

Batching machine model | PLD1200 |

Theoretical production efficiency (m³/h) | 35 |