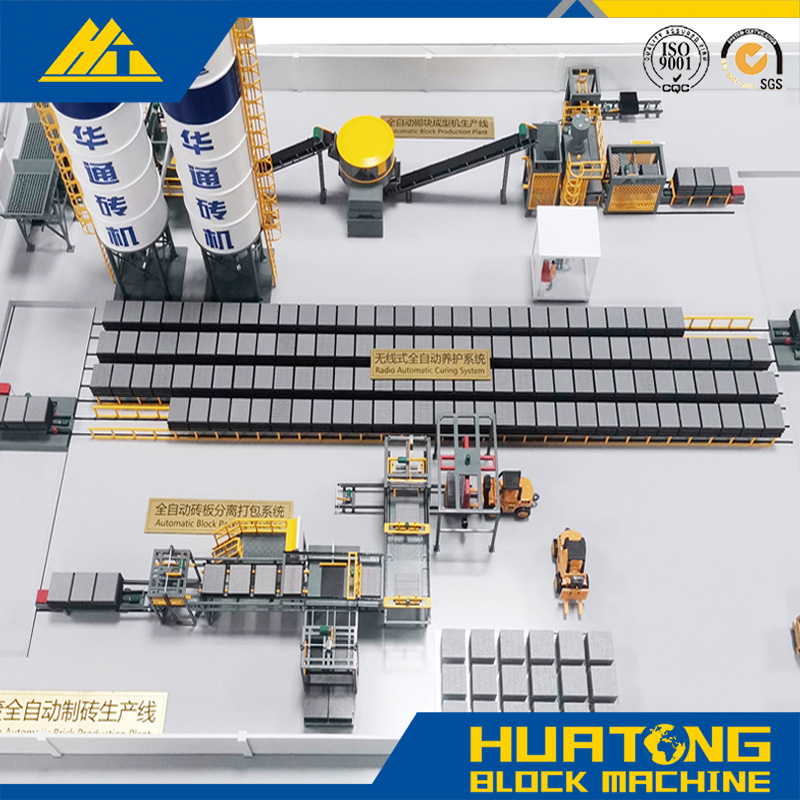

Automatic Brick Production Line

The production line can produce high-strength and high-quality ordinary concrete blocks, sponge city permeable bricks, high-value-added imitation stone PC bricks, municipal curbstones and other products. It uses slag, fly ash and other waste as the main raw materials instead of conventional sand and gravel, which is green and environmentally friendly.

Product Description

Independently R&D and manufactured by Huatong, this series of block forming production lines integrates multiple self-developed core technologies, reflecting the company’s technical prowess. It adopts an optimized layout and seamless workflow. With years of market verification, the line offers complete configurations and consistent, dependable performance.

This production line can efficiently manufacture a range of products, such as high-strength, premium ordinary concrete blocks, sponge city permeable bricks, high-value-added stone-simulated PC bricks, and municipal curbstones. Its production process innovatively uses industrial wastes like slag and fly ash as main raw materials, replacing traditional sand and gravel, delivering both environmental benefits and economic value.

Core components of the line include a batching system, mixing system, automatic block forming machine, automatic elevator, automatic block separator, automatic cubing system, automatic packaging system, automatic conveying and circulation system, and a central control system, realizing full automation in operation.

Production Line Advantages:

Founded in 2004 and based in Gaotang, Shandong, Shandong Huatong Hydraulic Machinery Co., Ltd. is a technology enterprise specializing in designing, developing, and manufacturing comprehensive utilization equipment for bulk industrial solid waste. Our product range includes intelligent production lines for automatic block forming machines, automatic static pressure forming systems, high-precision assembled gypsum blocks, aerated concrete blocks, and vertical shaft planetary mixing stations. We also provide customized waste solutions and operational services. Supported by subsidiaries including Huatong Machinery, Avante Machinery, Darun Environmental Protection, and Cote d'Ivoire Shandong Group Company, we employ over 270 skilled engineers and technicians dedicated to delivering innovative and sustainable industrial equipment.

International clients visited our company for on-site inspections and engaged in in-depth discussions regarding product cooperation and quality details. We highly value every communication with our global partners and are committed to providing reliable products and professional services.

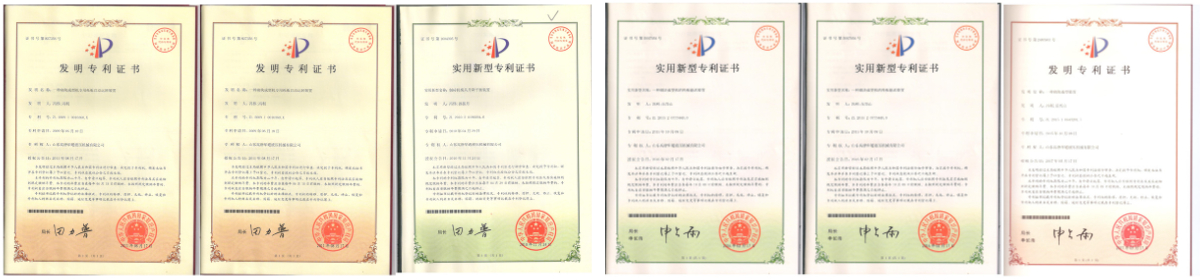

The following are some of the honors, qualifications, and certifications our company has received, which demonstrate our commitment to quality and professionalism.

FAQ

1. What raw materials are processable by Huatong's fully automatic static pressure brick production line?

It is capable of handling diverse raw materials like fly ash, coal gangue, construction waste, and clay. The system delivers uniform mixing and precise proportioning, making it well-suited for the efficient production of standard bricks, hollow bricks, and permeable bricks.

2. What is the production efficiency of Huatong's production line?

Featuring advanced automation technology, its daily output ranges from 50,000 to 110,000 standard bricks. PLC control optimizes workflow processes, reduces manual intervention, and ensures the stable, high-speed operation necessary for large-scale production.

3. What environmental merits does Huatong's production line possess?

t adopts a closed-loop operating process to minimize dust emissions. With low energy consumption and the recycling of wastes (e.g., industrial residues), it meets green production criteria and effectively lessens environmental impact.

4. What maintenance measures are needed for Huatong's static pressure brick production line?

Regular inspection of the hydraulic system and conveyor belt is vital. The user-friendly control panel sends timely fault alarms, and Huatong provides maintenance manuals and after-sales support to guarantee long-term stable operation.