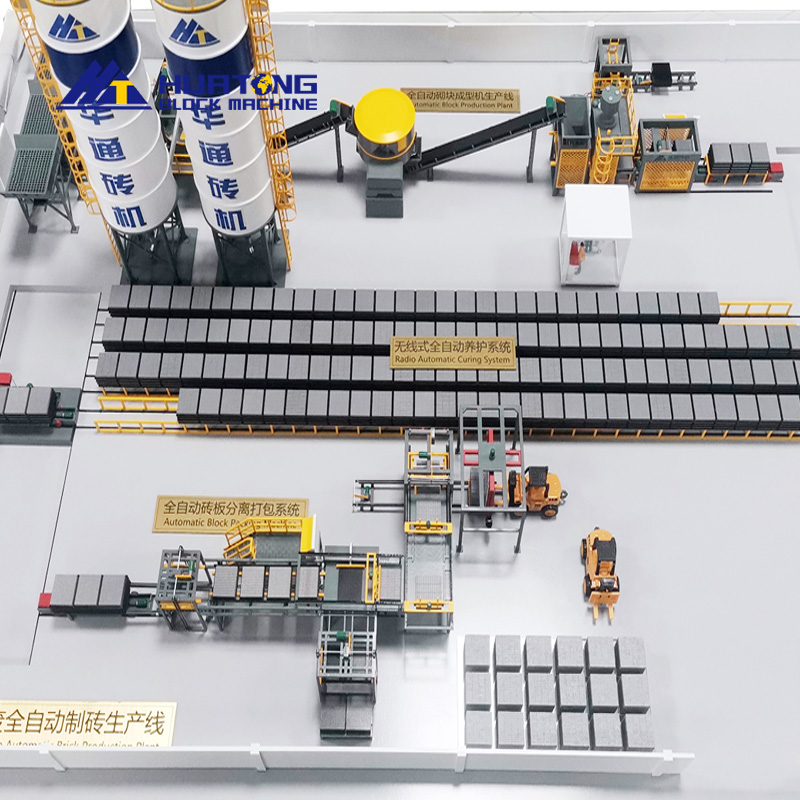

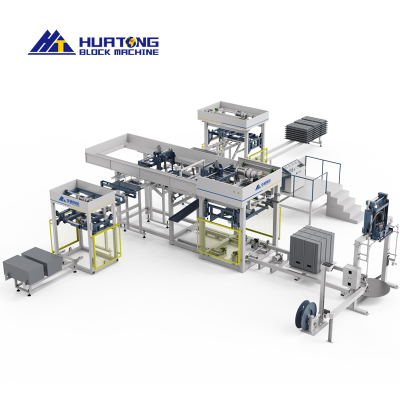

Fully Automatic Block Production-Line

This production line is capable of manufacturing high-strength, top-quality ordinary concrete blocks, sponge city permeable bricks, high-value-added stone-like PC bricks, municipal curbstones and other products. It adopts slag, fly ash and other wastes as primary raw materials in place of traditional sand and gravel, featuring environmental friendliness and sustainability.

Product Description

This series of block forming production lines, independently designed and manufactured by Huatong, integrates multiple independently developed core technologies, demonstrating the company's strength. The production line features a streamlined layout and a smooth process flow. Proven in the market over many years, it boasts comprehensive configurations and stable and reliable operation.

This line can efficiently produce a variety of products, including high-strength, high-quality ordinary concrete blocks, permeable sponge city bricks, high-value-added stone-like PC bricks, and municipal curbstones. The production process innovatively utilizes waste materials such as slag and fly ash as primary raw materials, replacing conventional sand and gravel, ensuring both environmental and economic efficiency.

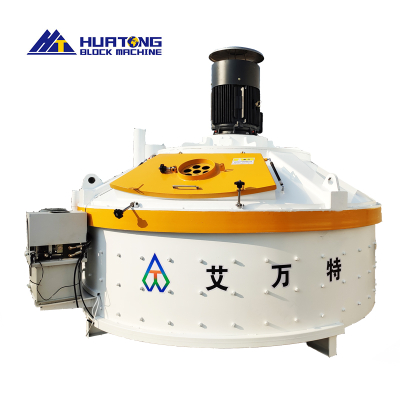

The production line's core components include a batching system, a mixing system, an automatic block forming machine, an automatic elevator, an automatic block divider, an automatic cubing system, an automatic packaging system, an automatic conveying and circulation system, and a central control system, achieving fully automated operation.

Production Line Advantages:

1. A well-organized footprint, high automation, and a comprehensive production line configuration enable automated production.

2. High reliability, advanced performance, and high stability.

3. High flexibility: Modular design and layout allow for customized products to meet individual needs.

4. A high degree of automation, including automated metering, mixing, conveying, transfer, warehousing, assembly, and billet production lines, significantly reduces labor input and costs.

Founded in 2004 and based in Gaotang, Shandong, Shandong Huatong Hydraulic Machinery Co., Ltd. is a technology enterprise specializing in designing, developing, and manufacturing comprehensive utilization equipment for bulk industrial solid waste. Our product range includes intelligent production lines for automatic block forming machines, automatic static pressure forming systems, high-precision assembled gypsum blocks, aerated concrete blocks, and vertical shaft planetary mixing stations. We also provide customized waste solutions and operational services. Supported by subsidiaries including Huatong Machinery, Avante Machinery, Darun Environmental Protection, and Cote d'Ivoire Shandong Group Company, we employ over 270 skilled engineers and technicians dedicated to delivering innovative and sustainable industrial equipment.

International clients visited our company for on-site inspections and engaged in in-depth discussions regarding product cooperation and quality details. We highly value every communication with our global partners and are committed to providing reliable products and professional services.

The following are some of the honors, qualifications, and certifications our company has received, which demonstrate our commitment to quality and professionalism.

FAQ

1. What raw materials are compatible with Huatong's fully automatic static pressure brick production line?

It can handle a range of raw materials including fly ash, coal gangue, construction waste, and clay. The system ensures uniform mixing and accurate proportioning, making it suitable for the efficient manufacturing of standard bricks, hollow bricks, and permeable bricks.

2. What is the efficiency level of Huatong's production line?

Equipped with advanced automation technology, its daily output can reach 50,000 to 110,000 standard bricks. PLC control optimizes the workflow, lowers manual involvement, and guarantees the stable, high-speed operation needed for large-scale production.

3. What environmental benefits does Huatong's production line offer?

It adopts a closed-loop process to minimize dust emissions. Low energy consumption and waste recycling (such as industrial residues) comply with green production standards, effectively reducing environmental impact.

4. What maintenance is required for Huatong's static pressure brick production line?

Regular checks of the hydraulic system and conveyor belt are essential. The user-friendly control panel provides timely fault alerts, and Huatong offers maintenance guides and after-sales support to ensure long-term stable operation.