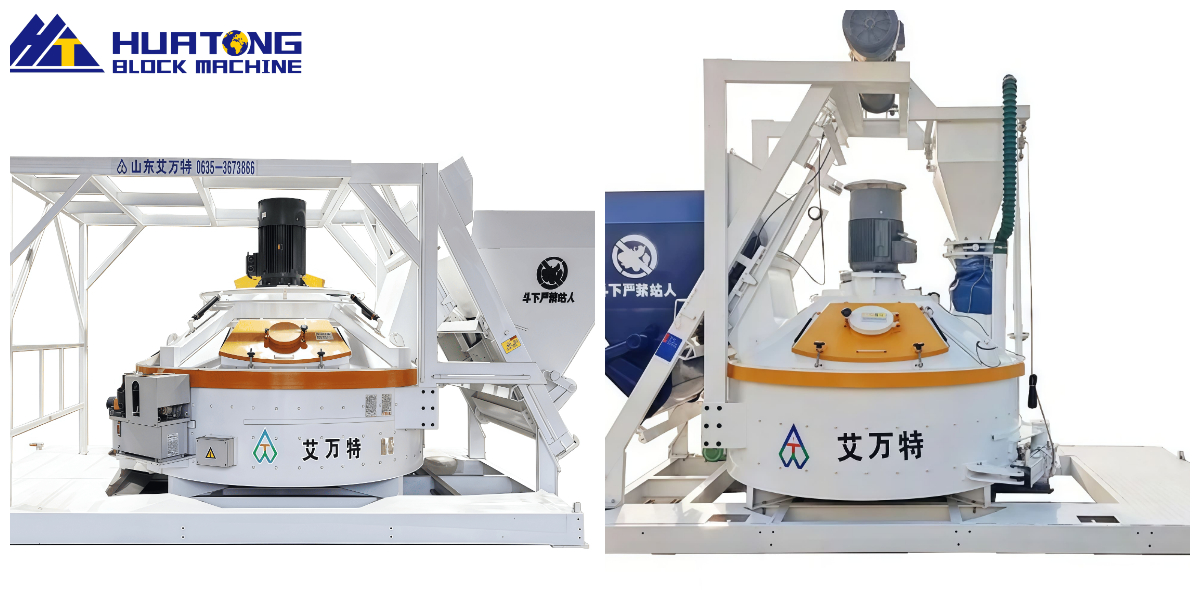

Planetary Bricks Mixer

The MPG-750 Planetary Bricks Mixer demonstrates significant engineering advantages through the following technical characteristics:

High-Capacity Precision Mixing Capability

The vertical shaft planetary mixing system delivers exceptional production capacity while maintaining precise mixing homogeneity. This ensures consistent mixing performance across all production batches, with scalable operational stability from laboratory to industrial scale. The system's multi-discharge gate configuration enables simultaneous servicing of multiple production lines in integrated concrete batching plants.

Reliable Operational Efficiency

Engineered for operational simplicity and maintenance optimization, the mixer demonstrates minimal failure rates and maintains stable performance through extended production cycles. Its compact structural design eliminates shaft sealing failures, substantially reducing operational interruptions, repair requirements, and lifetime maintenance costs.

Vertical planetary mixers deliver high output and precision mixing, ensuring consistent performance across all unit sizes. When integrated into concrete mixing plants, they can be configured with multiple discharge gates to serve several production lines simultaneously

Specification | MPG750 |

Feeding Capacity (L) | 1125 |

Discharge Capacity (L) | 750 |

Discharge Mass (KG) | 1800 |

Mixing Rated Power (KW) | 30 |

Hydraulic Discharge Power (KW) | -- |

Number of Planets/Blades | 1/3 |

Side Scraper | 1 |

Discharge Scraper | 1 |

Mixer Weight (KG) | 3900 |

Hoist Power (KW) | 7.5 |

Overall Dimensions (L*W*H mm) | 2580*2340*2195 |

This vertical shaft planetary mixer integrates advanced technology with practical experience, featuring a scientifically designed structure. It combines high efficiency, low energy consumption, environmental friendliness, and a compact structure. It can operate independently or as the main unit in a batching plant, suitable for preparing various high-quality concretes. It operates safely and reliably, producing excellent mix quality.

Product Advantages

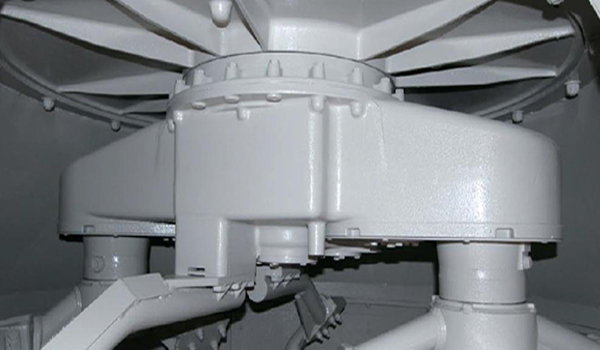

Unlike conventional designs, the planetary mixer's asymmetric arms thoroughly agitate the entire mixing volume, eliminating inefficient areas and boosting overall performance | |

Engineered with premium Siemens motors and bespoke reduction gearboxes, our drive system provides industry-leading load capacity while delivering three critical advantages: maximum torque output, whisper-quiet operation, and minimal power consumption | |

The mixing arm executes a precise planetary movement, simultaneously rotating on its axis and revolving around the central shaft. This dual motion generates complex, overlapping trajectories that thoroughly eliminate dead zones and mixing inefficiencies | |

The wear-resistant liners are fabricated from either NM500 steel or high-chromium alloy cast iron (KMTBCr15Mo2-GT). Each casting is permanently marked with a unique identifier to facilitate the direct ordering of replacement components by maintenance teams. | |

Configured with six diagonally oriented nozzles, the atomization system achieves comprehensive area coverage for complete mixing humidity uniformity. | |

Our independently engineered hydraulic system ensures effortless door operation with its cushioned switching mechanism, delivering reliable daily performance with minimal maintenance requirements. |

Company Qualifications

![Planetary Bricks Mixer Planetary Bricks Mixer]()

Shipping and Logistics

![Planetary Bricks Mixer Planetary Bricks Mixer]()