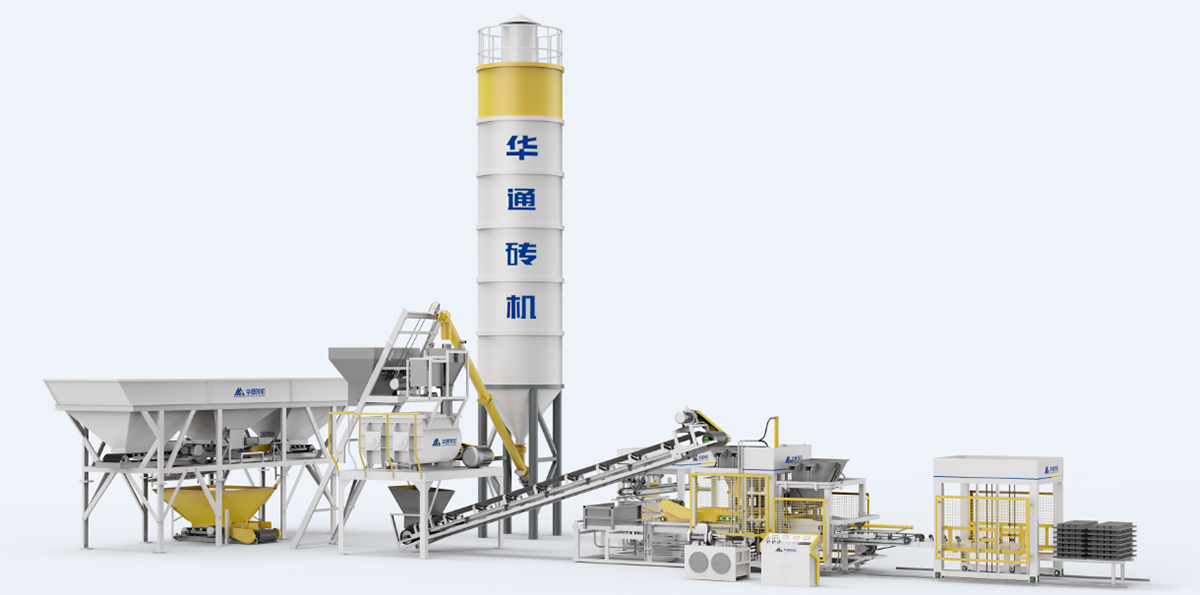

Automatic Brick Making Machine Production Line

Model: QT7-15

This Automatic Brick Making Machine Production Line is an environmental protection and waste utilization project, which can utilize various industrial solid wastes, stone powder, construction waste, etc. to produce various concrete products such as green environmental protection standard bricks, PC imitation stone bricks, artificial stone, and colored paving bricks.

QT7-15 fully automatic machine features and characteristics:

1. The machine body is constructed of ultra-strong steel using special welding technology, making it extremely sturdy and vibration-resistant.

2. Vibration system: Utilizing German frequency conversion technology and main unit frequency conversion control, the vibrator assembly is oil-immersed, improving brick density, saving energy, and accelerating molding.

3. Easy operation and management. The entire production process is fully computer-controlled. Once the initial data is set correctly, the system will operate accurately according to the established program. The control system features a fully user-friendly design that is simple to learn and intuitive to understand. General operators can quickly become independent operators after receiving the necessary training.

Technical parameters of QT7-15 fully automatic non-fired brick machine

Host power | 35.7KW | Exciting force | 75KN | |

Machine quality | 11T | Mold Rockwell hardness | ≥55 degrees | |

Dimensions | 3150×1900×2930mm | Pallet size | 1150*680*25mm | |

Molding cycle | 12-16 seconds/time | power distribution | 80KW | |

Production capacity | 30 million units /year | Implementation standards | JC/T920-2011 | |

(240*115*53mm) |

Output table of some products of QT7-15 fully automatic unburned brick machine

Technical parameters of QT7-15 fully automatic non-fired brick machine

Host power | 35.7KW | Exciting force | 75KN | |

Machine quality | 11T | Mold Rockwell hardness | ≥55 degrees | |

Dimensions | 3150×1900×2930mm | Pallet size | 1150*680*25mm | |

Molding cycle | 12-16 seconds/time | power distribution | 80KW | |

Production capacity | 30 million units /year | Implementation standards | JC/T920-2011 | |

(240*115*53mm) |

Output table of some products of QT7-15 fully automatic unburned brick machine

Block Type | Picture | Size(L×W×H) | Pcs./ Pallet | Pcs./ Hour | Pcs./ 8Hours |

Hollow Block | | 400x200x200mm | 7 | 1680 | 13440 |

Hollow Block |

| 400x150x200mm | 8 | 1920 | 15360 |

Hourdi Block | 200x100x60mm | 30 | 5400 | 43200 | |

Hollow Block | 530x160x195mm | 20 | 3600 | 28800 |

Performance and Features of the Production Line Equipment

1. The concrete placing boom employs a guided operation method to reduce mold load and uses forced material placement, ensuring uniform and dense material distribution and guaranteeing brick compaction.

2. An integrated vibration table and fully synchronous vibration mode enable the machine to achieve optimal compaction results.

3. A four-bar guide system and extended wear-resistant guide sleeves ensure precise movement of the mold and pressure head.

4. Major oil supply and electrical control components use imported components from Germany, Japan, and Denmark, ensuring simple operation and stable performance.

5. Molds, shafts, and other components undergo special processing, heat treatment, carburizing, and fine grinding, achieving a lifespan at a top-tier national level.

6. High degree of automation: Utilizing a Siemens central processing unit and Biduk sensors, the equipment operates automatically and cyclically without manual intervention. Its stable and reliable performance realizes a truly autonomous driving concept.

National quality certification

Logistics delivery guarantee

ShanDong HuaTong Hydraulic Machinery Co., Ltd. (hereinafter referred to as "Shandong Huatong") was founded in 2004 and is located in Gaotang, Shandong Province. It is a scientific and technological enterprise focusing on the design, research and development, production and sales of bulk industrial solid waste comprehensive utilization equipment. It has intelligent production line of automatic block forming machine, automatic static pressure forming machine production line, high-precision assembled gypsum block production line, aerated concrete block production line, vertical shaft planetary mixing station and other products, and waste scheme customization, preparation and operation services. It has member enterprises such as Huatong Machinery, Avante Machinery, Darun Environmental Protection, Cote d'Ivoire Shandong Group Company, and more than 270 engineers and technicians of all kinds.