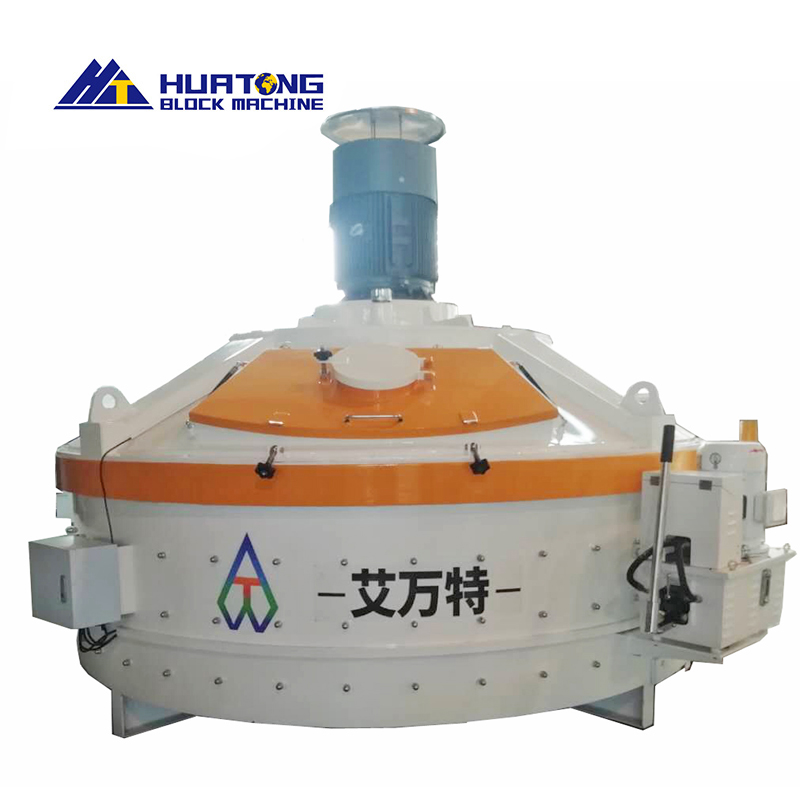

Brick Block Mixer

Model:MPG-2000 Brick Block Mixer

Optimized Production and Adaptability Advantages

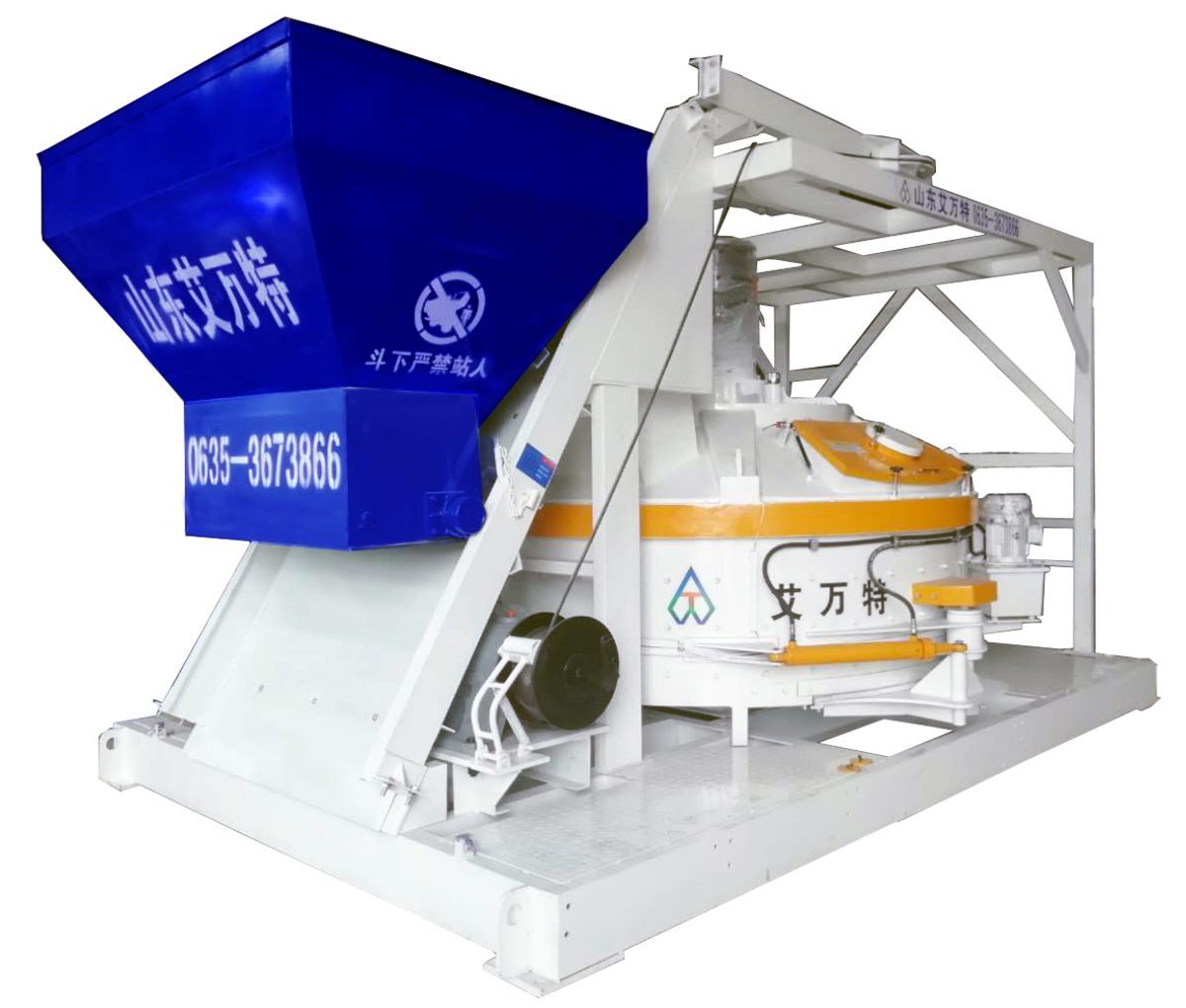

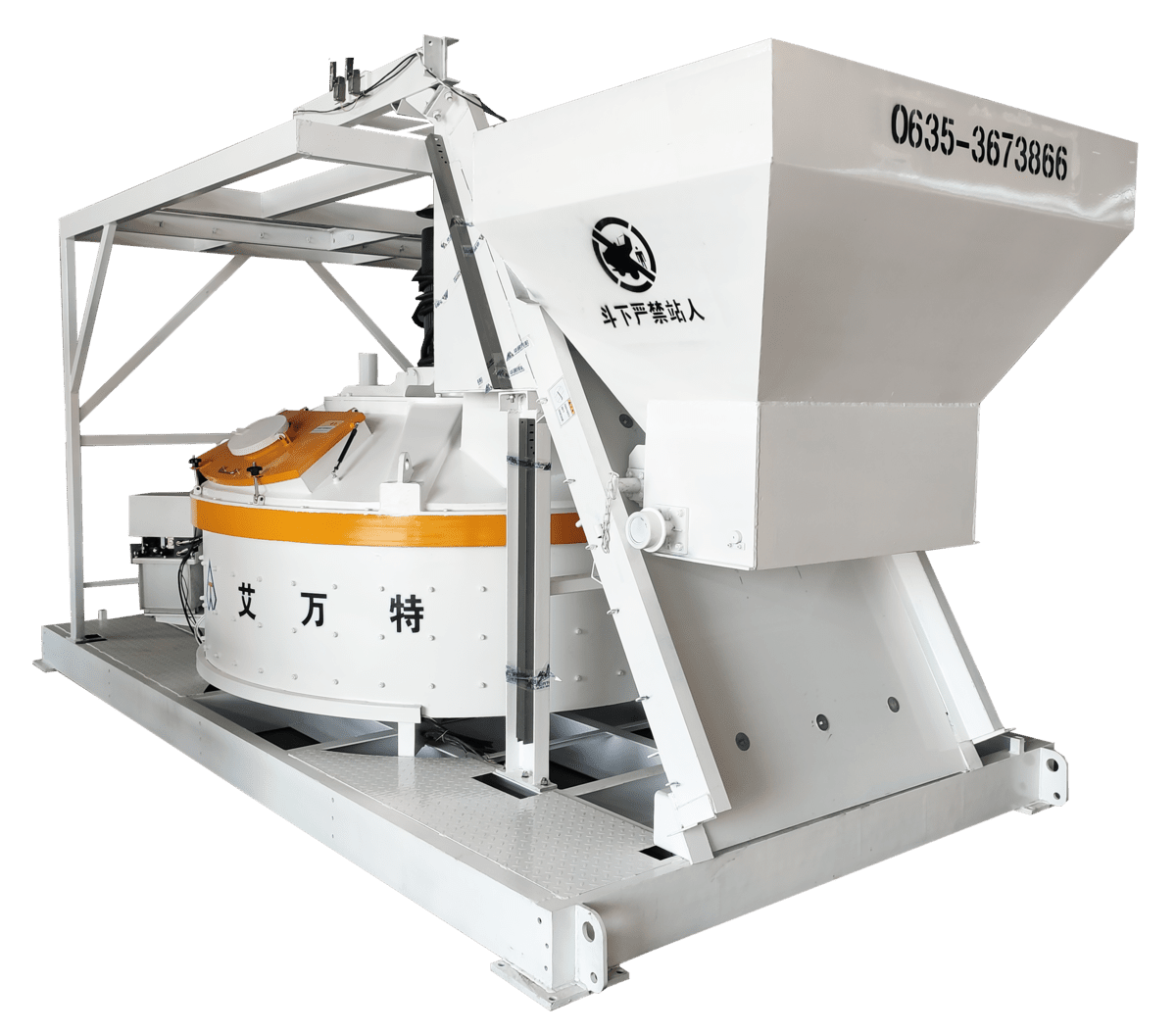

Vertical-shaft planetary mixers combine high production efficiency with precise mixing capabilities. Regardless of equipment size, their mixing performance remains stable, unaffected by model differences. When used in concrete batching plants, multiple discharge ports can be designed to meet production needs, enabling simultaneous feeding of multiple production lines and effectively improving overall production efficiency.

Optimized Operation and Maintenance Advantages

Vertical-shaft planetary mixers are not only easy to operate but also feature stable operation and a low failure rate. Their compact design saves installation space. Their shaft-leakage-free design fundamentally reduces the risk of failure, thereby lowering repair costs and routine maintenance workload, and minimizing losses from production line downtime.

Optimized Mixing Principle and Material Protection Advantages

Vertical-shaft mixers utilize planetary motion as their core mixing mechanism, ensuring a smooth and efficient mixing process. This mixing method preserves the original properties of the mixed material and prevents post-mixing stratification and agglomeration, ultimately ensuring quality in subsequent production steps.

MPG-2000Brick mixer

1. Better adaptability for specialty concrete. Conventional mixers are prone to uneven mixing and poor dispersion of additives when mixing high-grade, high-viscosity concrete or concrete containing special additives (such as fibers and expansion agents). The vertical-shaft planetary mixer structure creates a strong convection circulation, enabling thorough mixing of various specialty concretes, such as self-compacting concrete for precast components and refractory concrete, without requiring additional adjustment of mixing parameters, meeting diverse production needs.

2. Better energy and space efficiency. Compared to twin-shaft mixers of the same capacity, the vertical-shaft mixer has a more compact design, typically reducing floor space by 20%-30%. It is particularly suitable for small and medium-sized concrete plants or precast plants with limited space. Furthermore, the material resistance during mixing is more evenly distributed, the motor load is more stable, and the energy consumption per unit of output is lower, significantly reducing electricity costs over the long term.

3. Better cleanliness and environmental friendliness. If left unremoved after mixing, residual material can harden and clump, affecting the quality of the next mix and increasing equipment wear. The inner wall of the mixing chamber of the vertical shaft planetary mixer is smooth, and the mixing arm runs close to the chamber wall, which can reduce residual material accumulation; some models are also equipped with an automatic spray cleaning system, which makes cleaning more convenient and reduces dust pollution caused by manual cleaning, meeting environmentally friendly production requirements.

| Specification Item | Model: MPG2000 | |||

| Feeding Capacity (L) | 3000 | |||

| Discharge Capacity (L) | 2000 | |||

| Discharge Mass (KG) | 4800 | |||

| Mixing Rated Power (KW) | 75 | |||

| Hydraulic Discharge Power (KW) | 4 | |||

| Number of Planets/Blades | 3/6 | |||

| Side Scraper | 1 | |||

| Discharge Scraper | 2 | |||

| Mixer Weight (KG) | 8500 | |||

| Hoist Power (KW) | 22 | |||

| Overall Dimensions (LWH mm) | 3424*3217*2790 | |||

From outbound inspection to loading and securing, every step is strictly controlled to ensure that the equipment/cargo arrives intact. Subsequent logistics information will be synchronized immediately. If you have any questions, please feel free to contact us. We will escort you from beginning to end!

Product Advantages

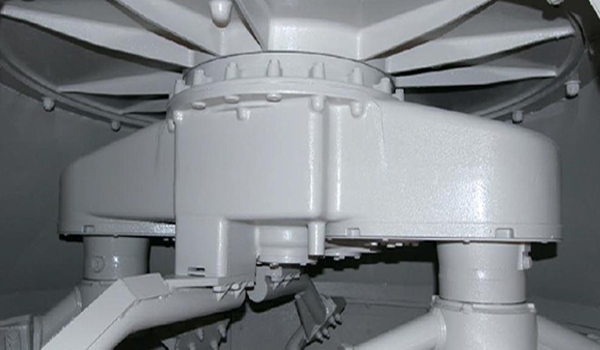

The planetary mixer's mixing arms have an asymmetrical structure, ensuring that no dead zones are generated during high-speed mixing within the mixing drum, thereby improving mixing efficiency. | |

The transmission system uses a powerful Siemens motor, and the reducer is a custom-made product from a renowned group. This high-end component gives the product a strong load-bearing capacity and significant advantages such as high output torque, low noise, and low energy consumption. | |

During the mixing process, the mixing arm rotates on its own axis while also revolving around a central point, resulting in complex and intersecting trajectories that prevent the formation of dead zones or inefficient areas. | |

Wear-resistant liners are made of NM500 steel or high-chromium wear-resistant alloy cast iron KMTBCr15Mo2-GT. Each cast iron part has a unique mark, which maintenance personnel can use to order replacement parts directly. | |

The water atomizing nozzle uses six nozzles spraying diagonally, which can cover a large area and make the mixing humidity more uniform. | |

The hydraulic pump station is independently developed and designed. The switch uses an engineering hydraulic cylinder with a buffer device, ensuring the smoothness and reliability of opening and closing the door. |

Company Qualifications

![Brick Block Mixer Brick Block Mixer]()

Shipping and Logistics

![Brick Block Mixer Brick Block Mixer]()

Shandong HuaTong Hydraulic Machinery Co., Ltd. (hereinafter referred to as "Shandong Huatong") was founded in 2004 and is located in Gaotang, Shandong Province. It is a scientific and technological enterprise focusing on the design, research and development, production and sales of bulk industrial solid waste comprehensive utilization equipment. It has intelligent production line of automatic block forming machine, automatic static pressure forming machine production line, high-precision assembled gypsum block production line, aerated concrete block production line, vertical shaft planetary mixing station and other products, and waste scheme customization, preparation and operation services. It has member enterprises such as Huatong Machinery, Avante Machinery, Darun Environmental Protection, Cote d'Ivoire Shandong Group Company, and more than 270 engineers and technicians of all kinds.