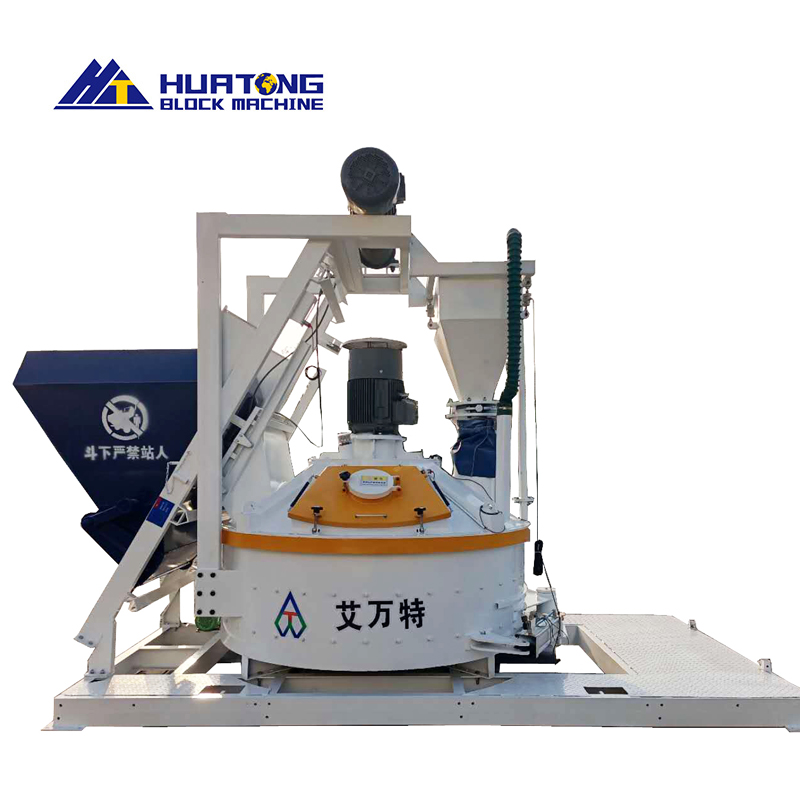

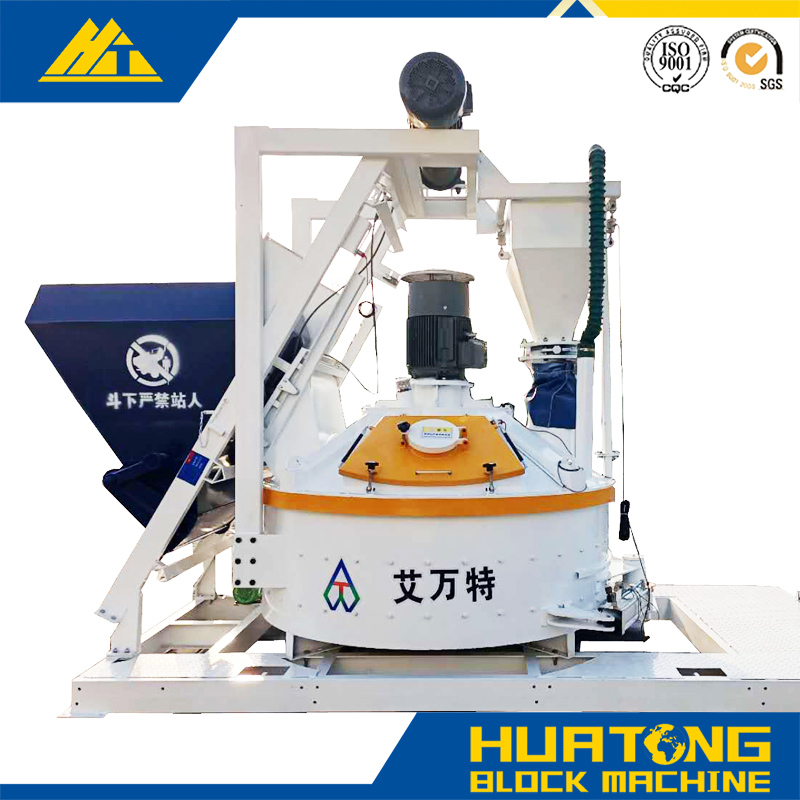

Vertical brick Mixer

Model:MPG-330

MPG-330 Vertical Shaft Mixer has reasonable design, stable operation, easy maintenance and low maintenance cost. It is equipped with powerful power to achieve high-precision mixing without damaging the mixing materials. The equipment has a high degree of automation and can mix a variety of materials. It is widely used in brick making, prefabricated components, refractory materials, metallurgy, glass and other fields.

Advantages of Vertical Shaft Mixers:

1. Vertical shaft planetary mixers offer high production capacity and precise mixing, ensuring consistent mixing performance across all units, regardless of size. Vertical shaft planetary mixers, when deployed in concrete mixing plants, can be designed with multiple discharge gates and serve multiple production lines simultaneously.

2. Vertical shaft planetary mixers are easy to operate, offer low malfunction rates, stable operation, and a compact design. They are free of shaft leakage, significantly reducing malfunctions, repair costs, and maintenance.

3. Vertical shaft mixers utilize a planetary motion concept for mechanical mixing, ensuring smooth mixing without damaging the material, or causing stratification or clumping, thus preserving the original performance characteristics of the mixed material.

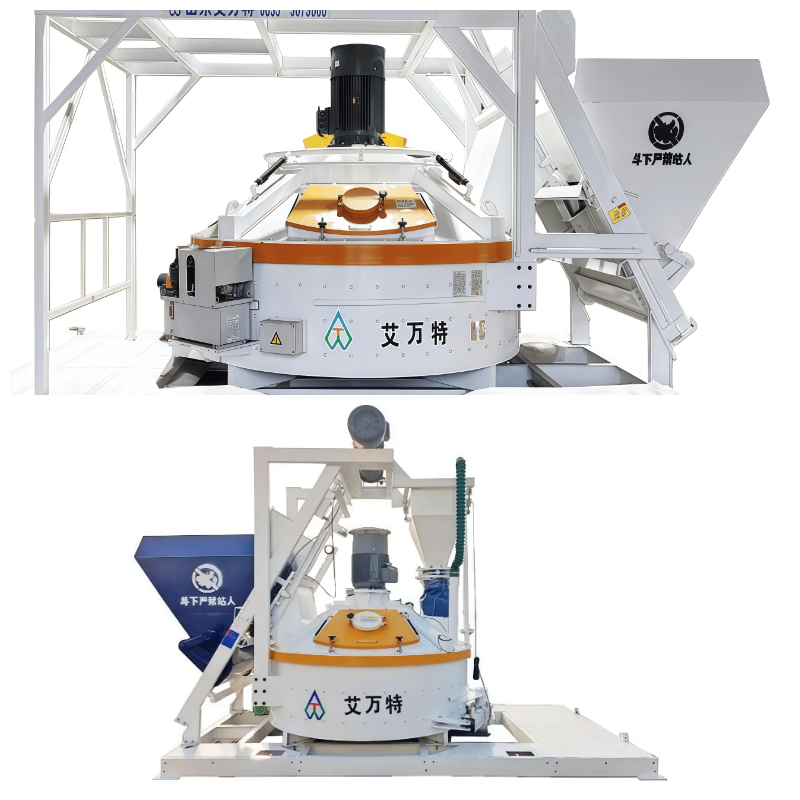

Specification Item | Model: MPG330 |

Feeding Capacity (L) | 500 |

Discharge Capacity (L) | 330 |

Discharge Mass (KG) | 800 |

Mixing Rated Power (KW) | 15 |

Hydraulic Discharge Power (KW) | -- |

Number of Planets/Blades | 1/2 |

Side Scraper | 1 |

Discharge Scraper | 1 |

Mixer Weight (KG) | 2000 |

Hoist Power (KW) | 4 |

Overall Dimensions (LWH mm) | 1870*1870*1855 |

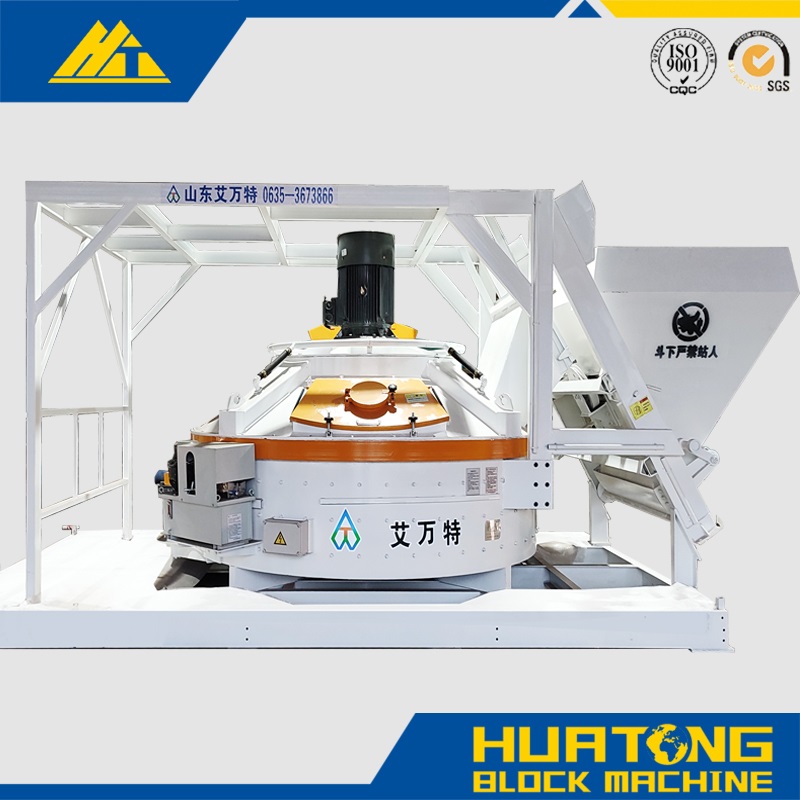

Product Advantages

The planetary mixer's mixing arms have an asymmetrical structure, ensuring that no dead zones are generated during high-speed mixing within the mixing drum, thereby improving mixing efficiency. | |

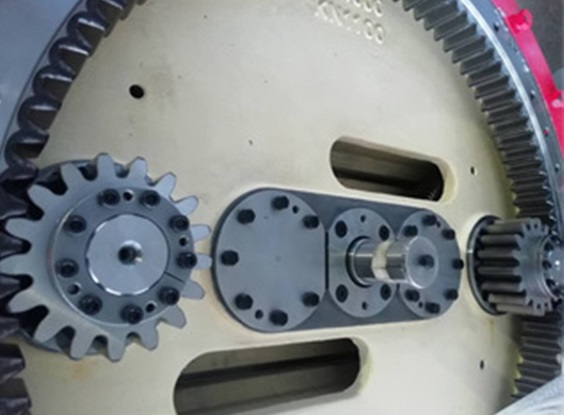

The transmission system uses a powerful Siemens motor, and the reducer is a custom-made product from a renowned group. This high-end component gives the product a strong load-bearing capacity and significant advantages such as high output torque, low noise, and low energy consumption. | |

During the mixing process, the mixing arm rotates on its own axis while also revolving around a central point, resulting in complex and intersecting trajectories that prevent the formation of dead zones or inefficient areas. | |

Wear-resistant liners are made of NM500 steel or high-chromium wear-resistant alloy cast iron KMTBCr15Mo2-GT. Each cast iron part has a unique mark, which maintenance personnel can use to order replacement parts directly. | |

The water atomizing nozzle uses six nozzles spraying diagonally, which can cover a large area and make the mixing humidity more uniform. | |

The hydraulic pump station is independently developed and designed. The switch uses an engineering hydraulic cylinder with a buffer device, ensuring the smoothness and reliability of opening and closing the door. |

Company Qualifications

![Vertical brick Mixer Vertical brick Mixer]()

Shipping and Logistics

![Vertical brick Mixer Vertical brick Mixer]()