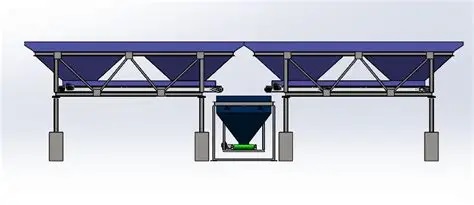

Bricks Machine Ingredients

The PLD Bricks Machine Ingredients are a new type of batching machinery, widely used in general construction sites, road construction, bridge construction, and other engineering scenarios. Specifically developed for brick batching, the PLD2400 four-compartment batching machine features a sturdy structure and exceptional durability. This equipment utilizes center-discharging technology, ensuring smooth, blockage-free unloading even when the brick-making raw materials are damp. It also incorporates Huatong's patented oscillating screening system, significantly improving screening efficiency and extending the life of the screen. Furthermore, each of the four compartments is equipped with a conveyor discharge mechanism, enabling precise raw material weight measurement to ensure batching accuracy meets production requirements.

1. Simultaneous processing of multiple raw materials, adapting to complex formulations

It supports independent storage and metering of four raw materials with different characteristics (such as sand, cement, additives, and auxiliary materials). This eliminates the need for frequent silo changes or equipment adjustments, making it directly adaptable to multi-component mixing production scenarios (such as specialty concrete and composite building materials).

2. Improved mixing accuracy and more stable finished product quality

Using an independent weighing system with closed-loop feedback control, the metering error for each raw material can be controlled within ±0.2%. Compared to three- or two-bin systems, the overall ratio deviation of multi-component raw materials is further reduced. It supports the precise delivery of trace raw materials (such as functional additives). By using subdivided silos and high-precision feeding equipment (such as screw feeders), it avoids imbalances when mixing trace raw materials with bulk raw materials, ensuring the functional stability of the finished product.

3. Higher Production Efficiency and Smoother Process Integration

Four raw materials can be metered and conveyed concurrently, reducing waiting time compared to a multi-batch, single-bin processing model. Overall production efficiency is 20%-30% higher than a three-bin batching station, making it suitable for large-scale, continuous production. Each bin's conveying path seamlessly connects with the aggregation and mixing process. A PLC system synchronizes feeding and conveying speeds to prevent raw material accumulation or interruptions, ensuring continuous operation from raw material to finished product.

Serial number | name | Specification | quantity | unit | ||||

1 | PLD1200 | Raw material storage warehouse | 4m³ | 2 | indivual | |||

Shaking screen | 2800*2500 | 1 | indivual | |||||

Weighing bin | 2.4㎡ | 1 | indivual | |||||

sensor | ZMLBF-1000 | 3 | indivual | |||||

Motor | 3KW | 2 | tower | |||||

Scree Shaker Motor | 3KW | 1 | tower | |||||

Conveyor Belt | B500 | 3 | strip | |||||

Frame | Steel structure | 1 | set | |||||