Automatic Block Machine for sale

Model: QT5-15

Huatong QT5-15 Automatic Block Machine is a professional brick-forming machine manufacturer and supplier in China. Cement brick machines come in various types: fully automatic, semi-automatic, manual, mechanical, and hydraulic. A brick-forming machine utilizes raw materials such as slag, slag powder, fly ash, stone powder, sand, gravel, and cement. These materials are mixed in a scientifically formulated ratio with water, then pressed under high pressure to produce cement bricks, hollow bricks, or colored paving bricks.

Cement Brick Machine Product Features:

A rational design features an automatic pick-up and delivery plate system, material supply and distribution, forced distribution, and pressure head and mold frame synchronization, enabling automatic cycle production, high production efficiency, large brick output, and stable product quality.

The machine's mechanical, electrical, and hydraulic systems are interconnected, and PLC control, with program interlocking and self-protection, ensures safe and reliable operation. The main control console features a computer interface (with Chinese and English menus and an LCD touch screen) that allows machine parameter settings, random signal acquisition, fault diagnosis and analysis, and optimal machine operation. Remote communication also enables remote monitoring, fault detection, and system upgrades.

The machine utilizes a hydraulic motor vibration mechanism, offering a rational structure, reliable operation, high vibration efficiency, and an effective combination of pressure and vibration, resulting in a high product density. It has a wide range of applications and can produce a variety of concrete block types, including standard bricks, hollow bricks, lightweight bricks, and paving bricks.

| Item | Specification |

Overall Dimensions | 3000×1900×2930mm |

Molding Method | Table Vibration |

Pallet Size | 1150×580×25–40 mm |

Rated Pressure | 21 MPa |

Hydraulic Station Power | 18.5 kW |

Forming Cycle | 15–20 seconds per cycle |

Mold Rockwell Hardness | ≥ 55 HRC |

Applications | Construction Industry: production of concrete hollow and solid blocks. |

Raw Materials | Cement, sand, stone powder, gravel, slag, fly ash, and other building materials. |

Production Capacity

| Product Type | Image | Size (mm) | Per Molding | Cycle Time | Daily Output (10 hrs) |

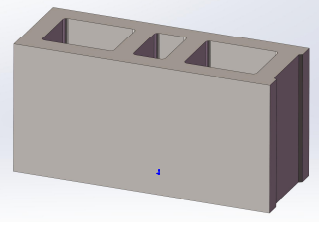

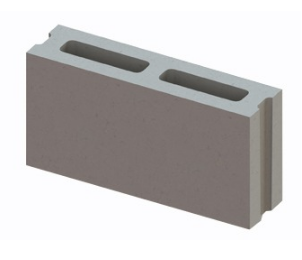

Hollow Block |  | 400×200×200 | 5 pcs | 15–20 s | 9,000–12,000 pcs |

Hollow Block |  | 400×150×200 | 6 pcs | 15–20 s | 10,800–14,400 pcs |

Hollow Block |  | 400×100×200 | 9 pcs | 15–20 s | 12,960–16,200 pcs |

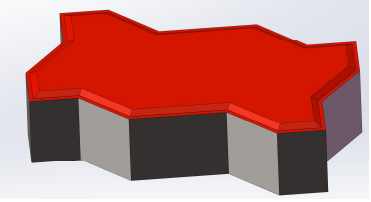

Paving Brick |  | 200×100×60 | 20 pcs | 20–25 s | 28,800–36,000 pcs |

Paving Brick |  | 225×112.5×60 | 16 pcs | 20–25 s | 23,000–28,800 pcs |

Shipping logistics guarantee

FAQ

How many types of cement are available based on local raw materials for each customer?

Answer: There are six types, namely Portland cement, ordinary Portland cement, slag Portland cement, pozzolanic Portland cement, fly ash Portland cement, and composite Portland cement. All of them can be used for making cement bricks.

What is included in the company's after-sales support?

Answer: 1-year warranty (excluding wear parts), with remote guidance and on-site training provided.