Brick Machinery

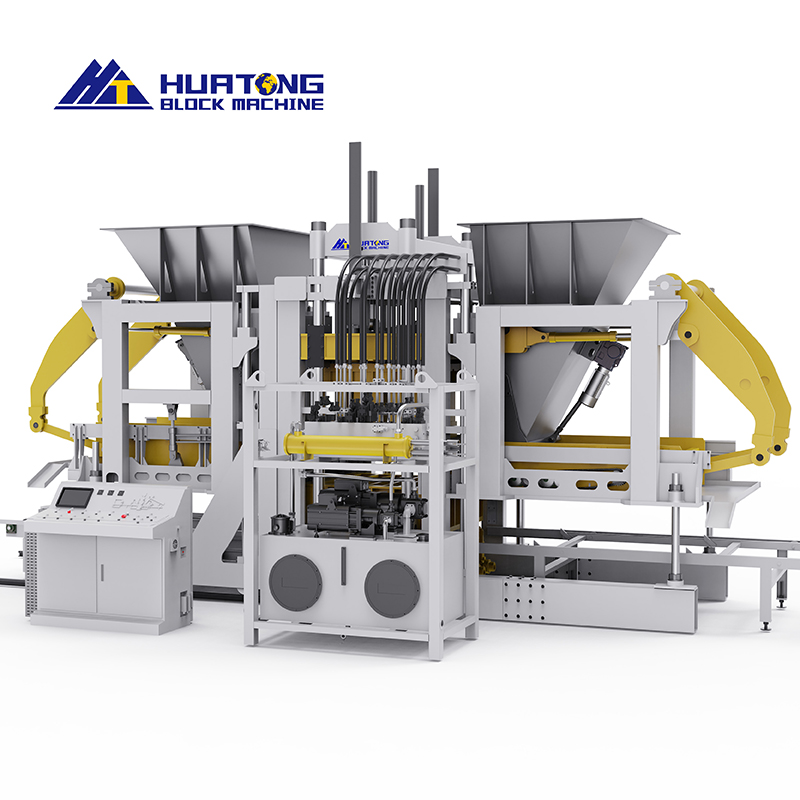

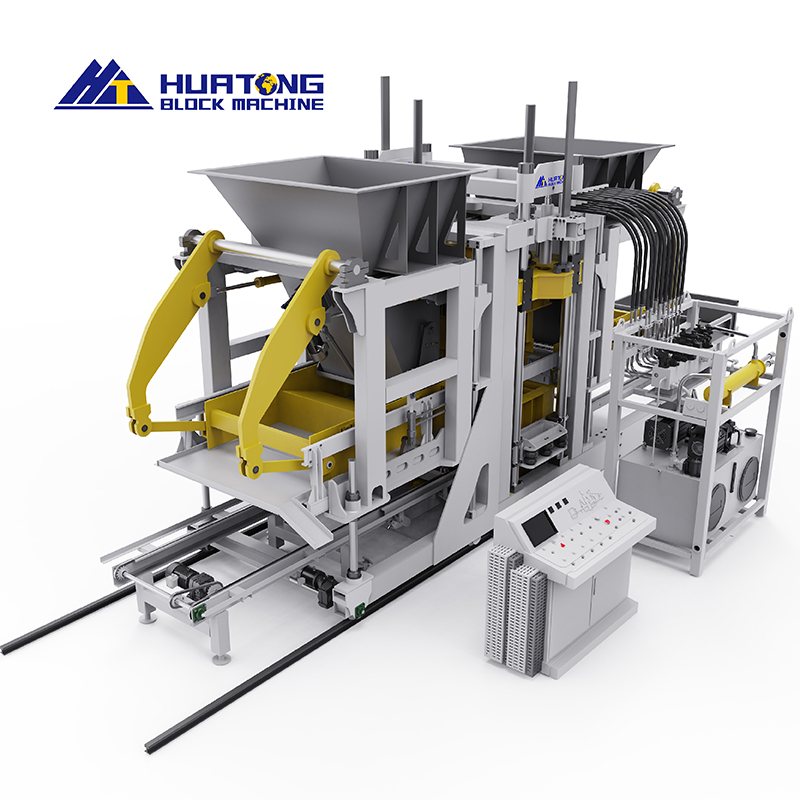

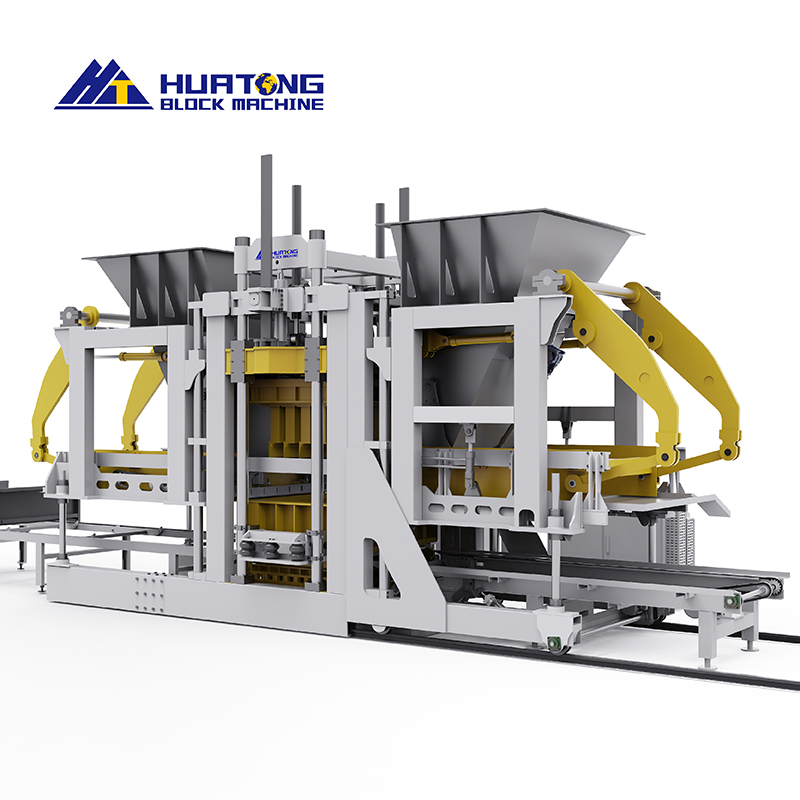

QT18-15 Brick machinery hydraulic system adopts Proportion Direction Valve. Automatic brick machinery valve can adjust flow rate and buffer cylinder during the process of production.Therefore,it can protect cylinder and extend life,and improve the speed and flexibility of each part.

Automatic Brick Machinery mould is made with heat treatments of quenching,tempering,carbonization and boriding.Working life of mould is improved.

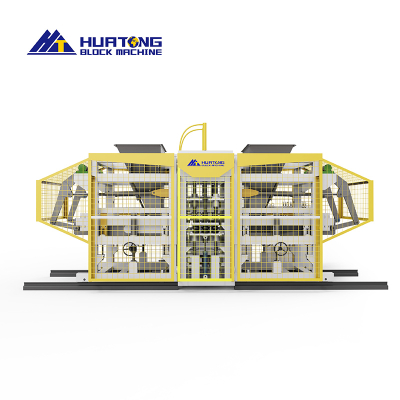

QT18-15 Brick Machinery is the 1 equipment designed, developed, processed and manufactured by Huatong Company in fully absorbing foreign advanced technology and technology. All key electronic control components, motor reducers, hydraulic and pneumatic components are all well-known foreign brand products, so as to ensure the high reliability of equipment operation. Brick machinery is more user-friendly in terms of appearance design, structural design, and convenient operation. The performance of the brick machinery has reached the level of similar products in the world, and it is a general-purpose equipment for processing concrete products with excellent performance.

QT18-15 Brick machinery technical parameter:

Dimension | 5000*2800*4500mm |

Mode of Vibration | Table Vibration |

Pallet Size | 1400*1400*30-40mm |

Rated Pressure | 21Mpa |

Oil Station Power | 22KW |

Cycle Time | 15-20'S |

Mould Rockwell Hardness(HRC) | ≥55 |

Application Category | Construction industry: production of concrete hollow blocks, solid bricks, etc. |

Raw Material | Cement, sand and gravel, stone powder, stone nitrate, slag, slag and other building materials |

Brick Machinery production capacity:

Block Type | Picture | Size(L x W x H) | Pcs./Pallet | Cycle Time | Pcs./8 Hours |

Hollow Block | 400x200x200mm | 18 | 15-20's | 25900-34500 | |

| Hollow Block | 400x150x200mm | 24 | 15-20's | 34500-46000 | |

| Hollow Block | 400x100x200mm | 33 | 15-20's | 47500-63300 | |

| Paving Block | 200x100x60mm | 66 | 20-25's | 76000-95000 | |

| Paving Block | 225x112.5x60mm | 45 | 20-25's | 51800-64800 |

Features of Brick Machinery:

1,Bionic crank arm type parallel bars cloth, improve the cloth speed and stability, reduce the failure rate.

2,The design of six guide columns and ultra-long guide sleeves increases the stability of equipment movement and the finished product size is more standard.

3,The hand-crank lifting device is more convenient and quick when changing the mold to adjust the height of the cloth machine.

Huatong Brick Machinery Honors and Certificates:

Packing and loading:

Shandong Huatong Hydraulic Machinery Co., Ltd. (hereinafter referred to as "Shandong Huatong") was founded in 2004 and is located in Gaotang, Shandong Province. It is a scientific and technological enterprise focusing on the design, research and development, production and sales of bulk industrial solid waste comprehensive utilization equipment. It has intelligent production line of Automatic block machine, automatic static pressure forming machine production line, high-precision assembled gypsum block production line, aerated concrete block production line, vertical shaft planetary mixing station and other products, and waste scheme customization, preparation and operation services. It has member enterprises such as Huatong Machinery, Avante Machinery, Darun Environmental Protection, Cote d'Ivoire Shandong Group Company, and more than 270 engineers and technicians of all kinds.

FAQ:

Q1. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q2.How about your delivery time?

A: Generally, it will take 15 day after receiving your advance payment if no special requirement.

Q3: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

A:2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.