Concrete Batching Plant

Model:HZN50Concrete Batching Plant

Advantage:

Application Scope & Industry Adaptability

The system is engineered to support small and medium-scale construction projects as well as commercial concrete production. It is ideally suited for critical infrastructure development—including hydropower stations, aviation facilities, highway networks, bridge construction, and building projects—and extends to the manufacturing of precast components such as pipe piles, cement pipes, and brick production systems.

Concrete Batching Plant Overview

The MPG1000 vertical planetary mixer serves as the core mixing unit, paired with a PLD1600 precision batcher. This configuration is specifically engineered for large-scale infrastructure projects—including hydropower, energy, and bridge construction—requiring sustained concrete production at distributed sites with extended project timelines.

Technical Features

Advanced Dust Management

Integrated centralized control with negative-pressure pulse filtration delivers environmentally compliant dust suppression.

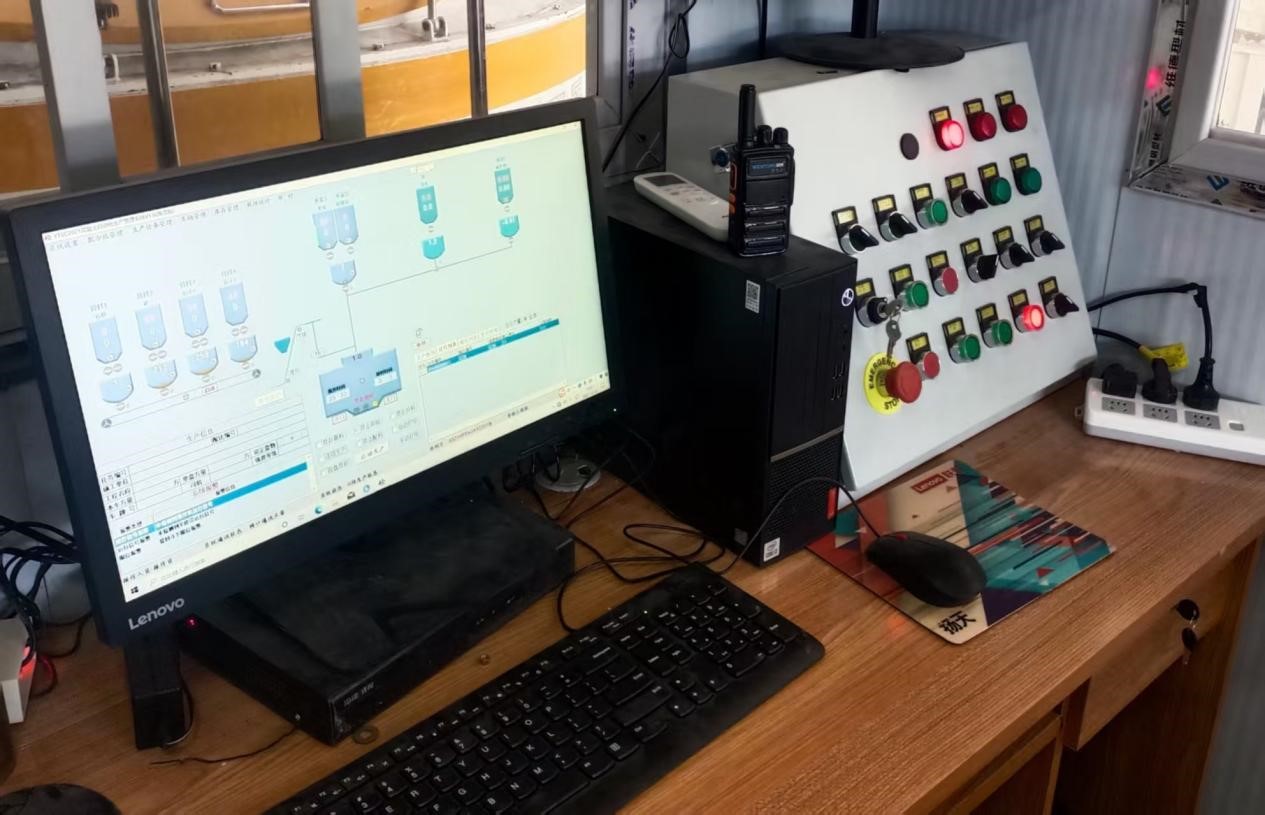

Automated Process Control

An intuitive yet robust control platform provides operational stability while enabling batch correction, weight compensation, continuous production, and intelligent fault diagnostics.

2. Batching machine: two types: cumulative metering and separate metering

3. Metering system: including water metering, cement metering, and admixture metering

4. Control system: divided into two types: full computer automatic control and touch screen automatic control

Mixing plant model | HZN50 |

Host model | MPG1000 |

Batching machine model | PLD1600 |

Theoretical production efficiency (m³/h) | 50 |