Ready Mix Concrete Plant

Model:The HZN75 Ready Mix Concrete Plant

1. It is suitable for small and medium-sized construction projects and commercial concrete production, such as hydropower projects, airports, highways, bridges, buildings, and pipe piles, cement pipes, and brick machines.

2. It utilizes a vertical-shaft planetary mixer, offering excellent mixing quality, short mixing cycles, and high efficiency. The control system is simple to operate, stable, and reliable, and features multiple functions, including re-weighing, de-weighing, continuous production, and intelligent alarms.

3. Various designs and installation options are available to meet user needs.

Concrete Mixing Plant Introduction

The concrete batching plant uses an MPG1000 vertical-shaft planetary mixer as the main unit and a PLD1600 batching machine as the batching machine. It is commonly used in large and medium-sized water conservancy, power, and bridge projects with small concrete volumes, long construction periods, and concentrated construction sites.

Features:

Technical Features

Self-Cleaning Mixer

Vertical planetary mixing system prevents material adhesion to shaft and cover, eliminating manual cleaning.

Enhanced Hopper Longevity

Wear-resistant concrete receiving hopper provides ≥5x service life improvement over conventional designs.

Leak-Proof Additive Dosing

Advanced sealing technology ensures precise chemical admixture measurement and operational safety.

Intelligent Water Management

Pressurized water discharge system enables precise slump control through regulated water injection/drainage.

Rapid Deployment

Modular architecture with automated workflows reduces installation/commissioning time by 40-60%.

The control system is simple to operae, stable, and reliable, with multiple functions including re-weighing, de-weighing, continuous production, and intelligent alarms.

Avant concrete mixing station consists of four main components:

1. Vertical planetary mixer, platform, and lifting system (with belt loading and bucket loading).

2. Batching machine: two types: cumulative metering and separate metering

3. Metering system: including water metering, cement metering, and admixture metering

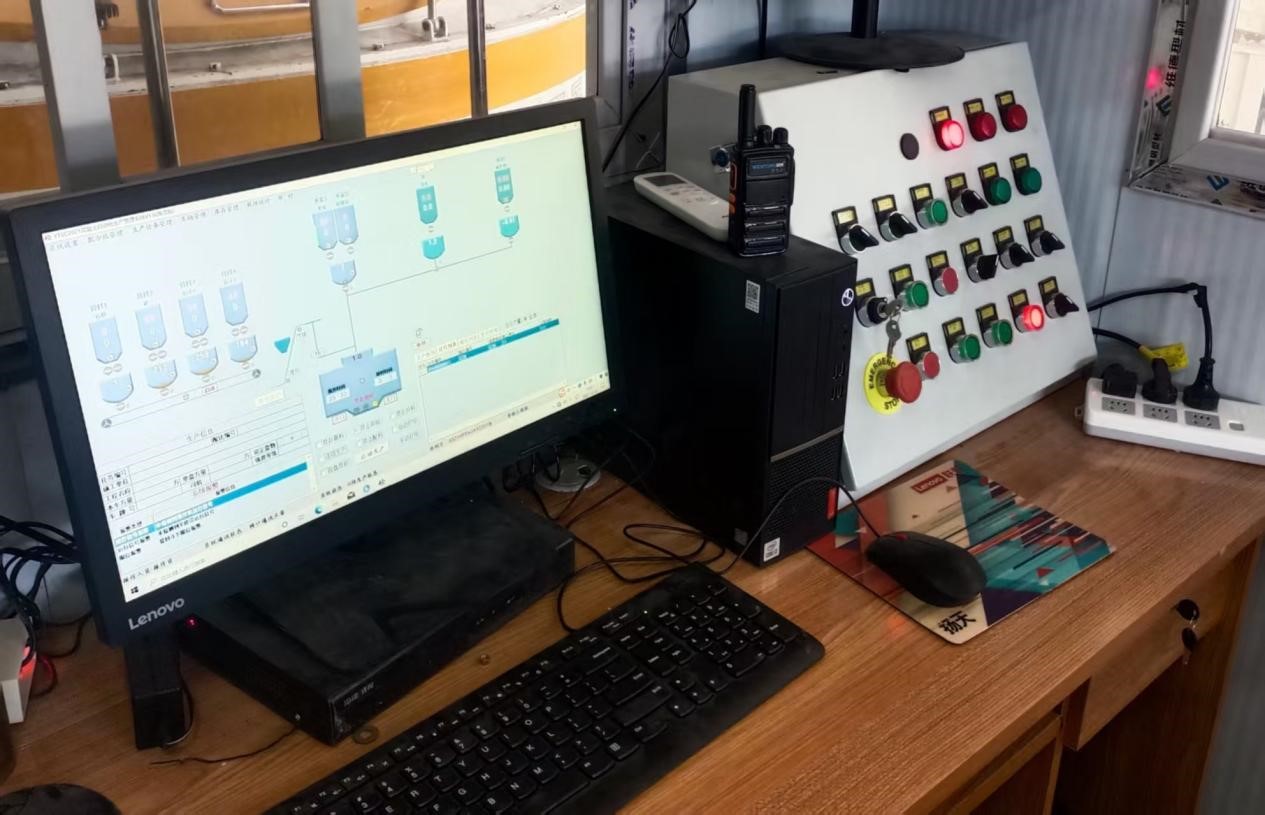

4. Control system: divided into two types: full computer automatic control and touch screen automatic control

Mixing plant model | HZN75 |

Host model | MPG1700 |

Batching machine model | PLD2400 |

Theoretical production efficiency (m³/h) | 75 |