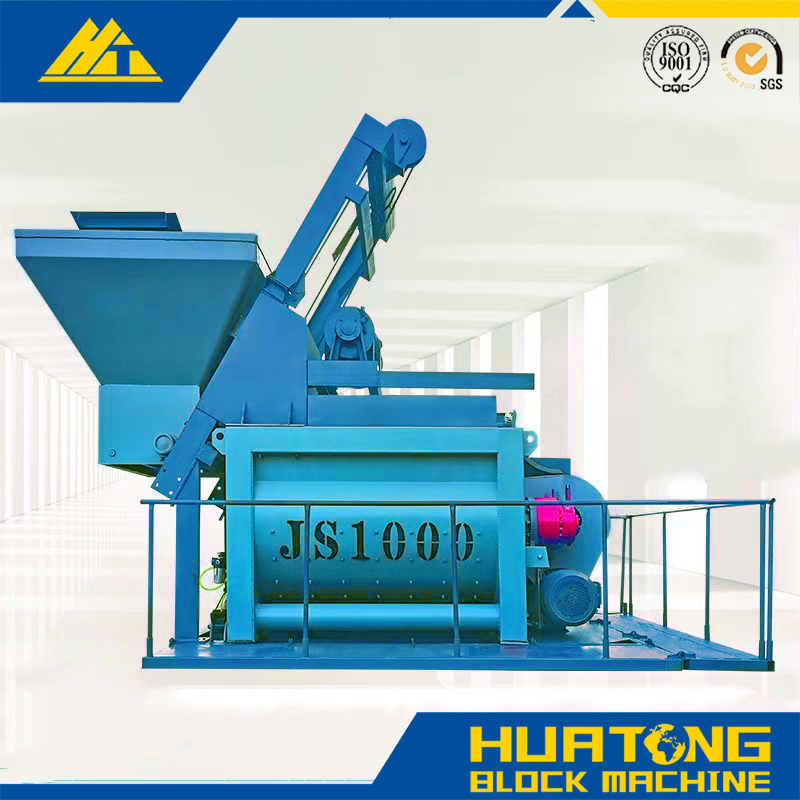

The JS1000 Twin-Shaft Forced Concrete Mixer, a top-tier Concrete Mixer, enhances mixing accuracy through advanced twin-shaft configuration. It achieves thorough, consistent blending for dense materials—surpassing traditional Cement Mixers in uniformity, a vital factor for large-scale projects and brick-manufacturing lines.

As a heavy-duty Cement Mixer, the JS1000 increases productivity for high-intensity construction with swifter cycles than smaller-sized models. For buyers seeking a Concrete Mixer For Sale for high-output brick production, its large capacity and operational efficiency make it a superior choice.

Performance parameters:

| Model | JS1000 | |

| Discharging Capacity (L) | 1000 | |

| Feeding Capacity (L) | 1600 | |

| Productivity (m³/h) | ≥50 | |

| Maximum Aggregate Size (Gravel/Crushed Stone) (mm) | 80/60 | |

| Mixing Blade | Rotation Speed (r/min) | 25.5 |

| Quantity | 2 X 8 | |

| Mixing Motor | Model | Y225S-4 |

| Power (KW) | 37 | |

| Hoist Motor | Model | YEZ160S-4-B5 |

| Power (KW) | 11 | |

| Water Pump Motor | Model | KQ65-100 1 |

| Power (KW) | 3 | |

| Hopper Lifting Speed (m/min) | 21.9 | |

| Overall Dimensions (Length×Width×Height) | Transport State | 4640X2250X2250 |

| Working State | 8765X3436X9540 | |

| Overall Mass (kg) | 8700 | |

| Discharging Height (mm) | 2700&3800 | |

Product details display

| Made of high-quality thickened reinforced steel, the twin-shaft concrete mixer’s core components are rigid, wear-resistant, and deformation-resistant—even under prolonged heavy loads. Heat-treated and precision-rolled, the steel withstands abrasive mixing and cyclic stress, avoiding flexing or warping for consistent, long-lasting performance. |

All-copper motor: Equipped with a premium all-copper winding motor, it boasts excellent high-temperature resistance, enabling continuous long-lasting operation without overheating or burnout. The all-copper construction enhances heat dissipation and electrical conductivity, effectively withstanding harsh working conditions and cyclic loads, ensuring reliable performance and extended service life. |  |

| Thickened solid shaft: Adopts a stainless steel thickened solid shaft design, featuring enhanced rigidity and torque transmission capacity for more uniform, efficient mixing. The corrosion-resistant stainless steel and thickened solid structure ensure durability, withstanding heavy loads to maintain stable mixing performance. |

| Rising limiter: Equipped with a reliable rising limiter, it effectively prevents the hopper from hitting the top and delivers strong operational stability. The precision-designed limiter ensures sensitive response and stable performance, safeguarding equipment safety during hopper lifting. |  |

| Mixer lining & blades: Undergoes precision machining and premium material selection, enhancing wear resistance and mixing efficiency. The carefully chosen materials and precise processing ensure long service life and consistent mixing results. |

| Manual lubrication pump: Enables precise oil delivery and stable lubrication for key components, with a large-diameter oil cap for easier refueling. The anti-slip, anti-falling handle cover enhances operational safety and convenience during use. |  |