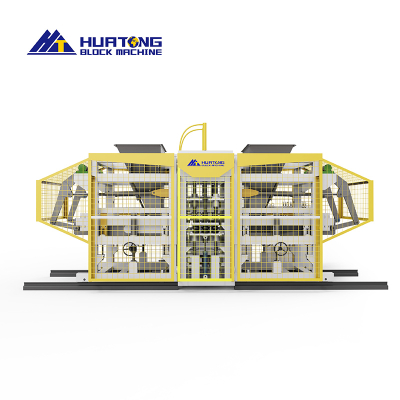

Hydraulic Brick Press Machine

Static Pressure Molding: High Quality with Low Noise:The unique static pressure molding technology effectively addresses the industry challenge of insufficient density in mid-density materials while significantly reducing equipment operation noise.

High ROI with Comprehensive Advantages:Combining the strengths of large-tonnage static pressure and vibration molding technologies, it delivers high performance while offering low investment costs and high returns, making it an ideal solution for small and medium-sized enterprises.

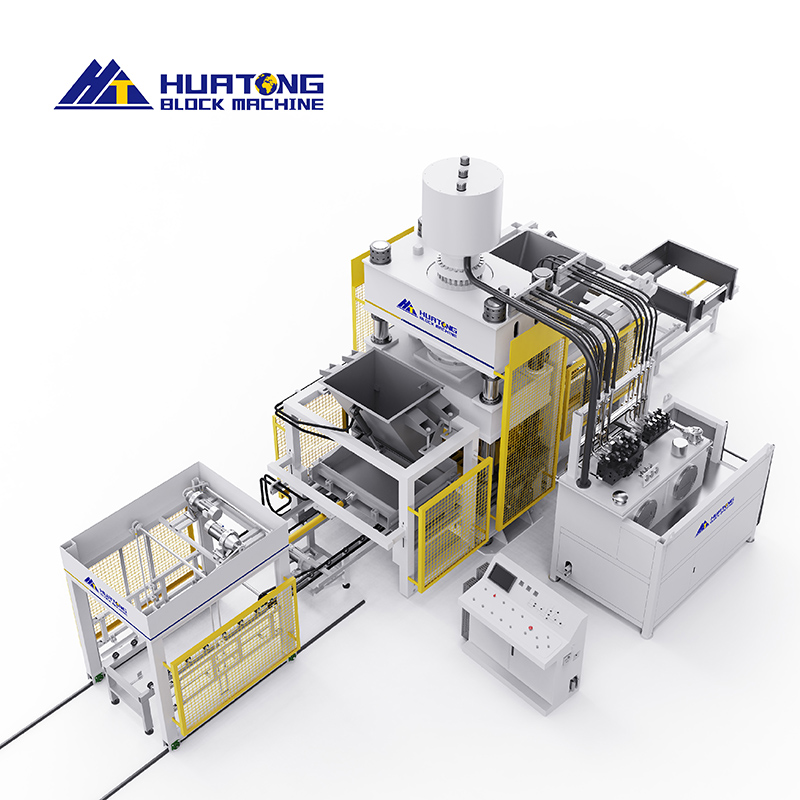

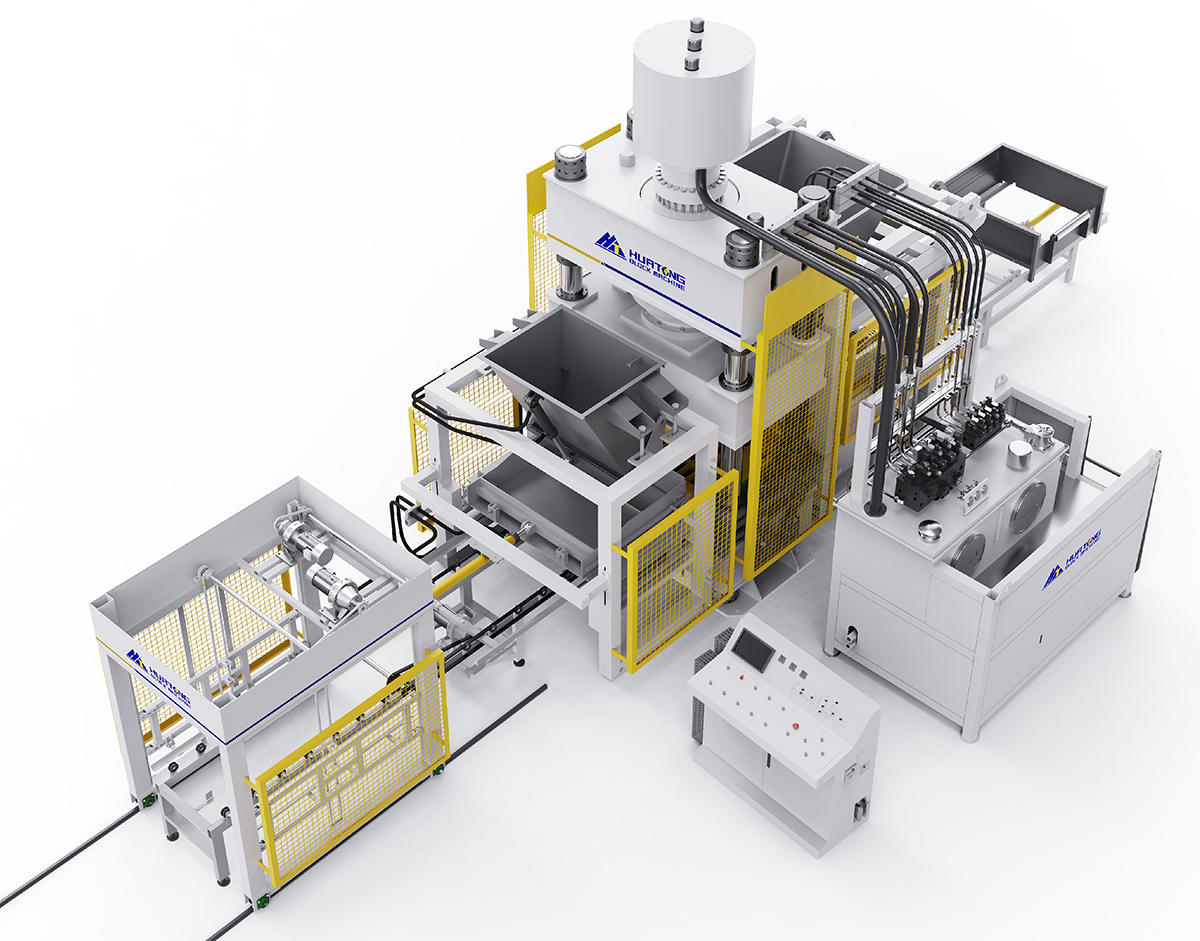

The HT1100 Hydraulic Brick Press Machine is a new type of brick-making equipment independently developed by our company. It integrates the advantages of large-tonnage static pressure machines and conventional vibration-pressure molding machines, effectively solving the problems of insufficient density for mid-density materials and high noise during molding with conventional equipment. As a result, this machine offers a wide range of material applicability, low noise, low investment, and high returns, earning consistent praise from customers.

The HT1100 is an integrated mechanical, electrical, and hydraulic system. Key components such as the oil station and control cabinet utilize internationally renowned brands. It features stepless speed change, timely fault prompts, and early warnings, while also enabling remote control, fault diagnosis, and system upgrades, providing convenience for promptly meeting customer needs. During production, simply replacing the molds allows for the production of various specifications of paving bricks, PC bricks, and more. By adding an appropriate amount of soil solidifier, it can also process tailings sand, tailings mud, shield tunneling mud, and other materials, making it an ideal solution for general enterprises engaged in eco-friendly brick production and waste treatment.

Technical Parameter:

HT1100 Model Technical Parameter | |

Working Pressure | 1100KN |

Brick Production Per Cycle | 51 |

Press Cycle | 14-18S |

Pressing Mode | Double Direct Press |

Maximum Hydraulic Pressure | 31.5Mpa |

Mould Open Size | 1540x1160mm |

Percentage of Coal Fly Ash | 70% |

Brick Production Per Year | 75,000,000 |

Coal Fly Ash Consumption | 13,0000-15,0000Tons |

Power | 125.4kw |

Weight | 50T |

Exhaust Times | More Than 3 times(Adjustable) |

Maximum Mould Height | 400mm |

Production Capacity:

Product Type | Image | Size(mm) | Per Molding | Cycle Time | Daily Output (10 hrs) |

Standard Brick | 238x114x50mm | 68pcs | 15-20s | 122400-163200 | |

Paving Block | 200x100x60mm | 44pcs | 15-20s | 79200-105600 | |

Paving Block | 230x115x60mm | 36pcs | 15-20s | 64800-86400 |

Product Details

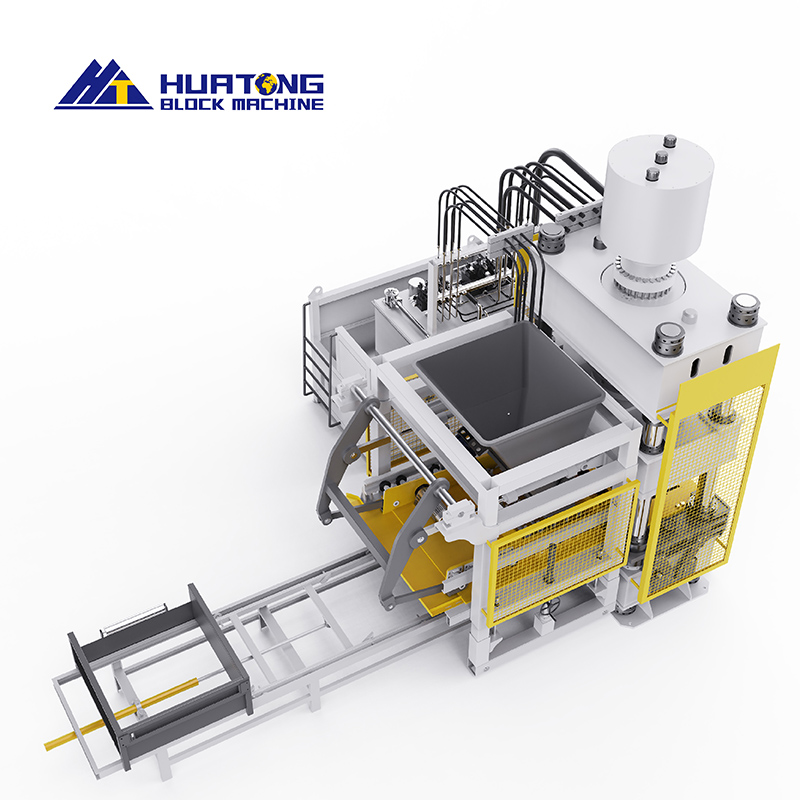

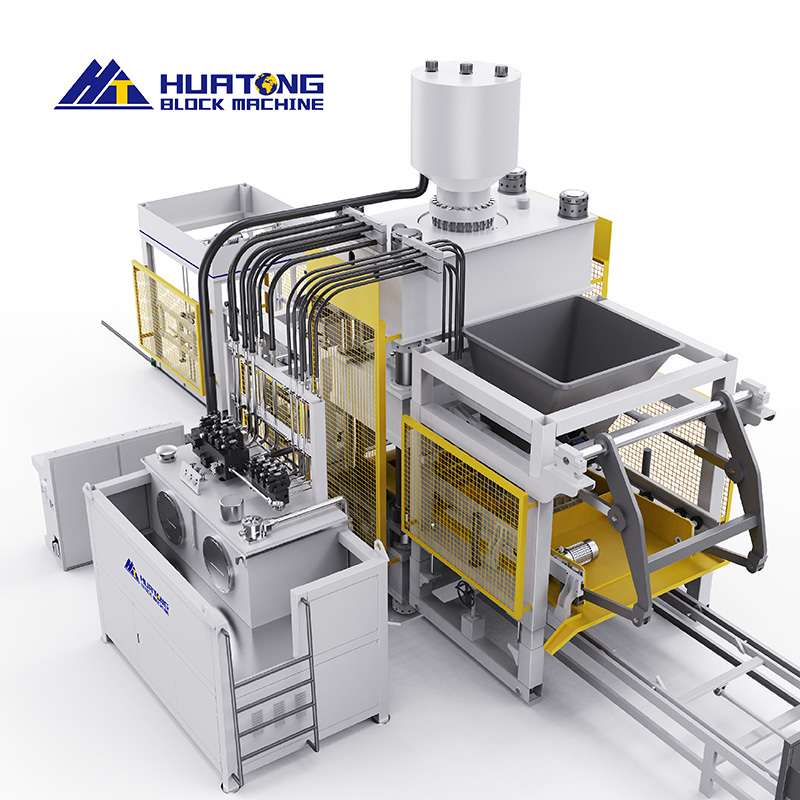

(1) The fully automatic hydraulic brick-making machine employs a five-beam and four-column structure. The mold frame is fixed on the central fixed beam. The upper and lower pressing heads are respectively fixed on the upper and lower movable beams. The brick-making machine is driven by the main hydraulic cylinder housed within the upper and lower fixed beams, with the upper and lower movable beams applying pressure to the brick molds in both directions. This ensures high compactness of the brick molds. Since the upper and lower punches are fixed on the upper and lower movables, which have been precision-machined, the four-column guide rods slide smoothly, fundamentally eliminating the possibility of the punches colliding with the mold walls. This brick-making machine not only operates at high speeds but also features minimal wear on the main hydraulic cylinder seals, making it less prone to damage and leaks, and resulting in a lower failure rate.

(2) The hydraulic system of the liquid-pressure brick-making machine features dual pumps and dual circuits. It employs specialized combined valve blocks to perform the work cycles of filling, venting, pressurizing, and releasing the mold.

(3) The brick-making machine’s hydraulic oil tank is equipped with an automatic oil temperature heating, cooling system, and a filtration device. Multiple continuous filtration processes are employed to ensure the optimal conditions for hydraulic oil usage.

(4) The feeding hopper of the brick-making machine is equipped with a level sensor and door-opening/closing cylinder, which enables the automatic opening and closing of the hopper door to ensure uniform feeding into the fabricating box. The automatic fabricating trolley employs a volumetric feeding method and is equipped with a forced mixing mechanism to ensure uniform distribution of the material and improve fabricating efficiency.

(5) By simply replacing the molds, it is possible to produce bricks of different specifications, such as standard bricks, blind-hole bricks, and hollow bricks.

Our Customers: