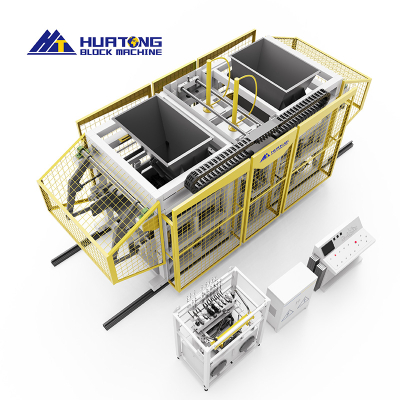

Fully Automated Concrete Block Machine Leads the Revolution, Ushering in a Green and Smart New Era in the Construction Industry

2026/01/15 14:35

With the accelerated advancement of construction industrialization, green and low-carbon development has become the core orientation of the industry. As a key piece of equipment in the building materials production sector, the fully automatic concrete block making machine is taking technological innovation as its driving force and profoundly reshaping the production mode and development pattern of the construction industry. Driven by multiple factors including the release of policy dividends, technological iteration and upgrading, and the expansion of application scenarios, fully automatic concrete block making machines will play an increasingly important role in the green transformation, efficiency improvement, and industrial upgrading of the construction industry in the future, leading the industry into a new stage of high-quality development.

Policy guidance has set the direction for industry development, ushering in a period of explosive demand for fully automatic concrete block making machines. In recent years, the country's "dual carbon" strategy has been continuously deepened. The 14th Five-Year Plan for the Development of the Construction Industry clearly puts forward the goal of achieving a 70% application ratio of green building materials by 2025, while the proportion of prefabricated buildings in newly built buildings needs to be increased to more than 30%. Against this backdrop, the transformation and upgrading of traditional building materials production models is imminent. Fully automatic concrete block making machines have emerged as important carriers to capitalize on policy dividends, thanks to their core advantages of high efficiency, environmental friendliness, and precision. Data shows that the domestic market size of fully automatic concrete block molding machines reached 4.26 billion yuan in 2024, and it is expected to exceed 5 billion yuan in 2025, with a compound annual growth rate (CAGR) maintaining above 12%. The continuous release of market demand provides strong impetus for equipment technology upgrading and industrial expansion.

Technological innovation drives industrial upgrading, with intelligentization and greenization becoming the core development directions. In the future, fully automatic concrete block making machines will accelerate their transformation towards "intelligent manufacturing". PLC intelligent control systems and IoT remote operation and maintenance platforms will become standard configurations. Through real-time data monitoring and intelligent regulation, precise control over the entire production process will be achieved, significantly improving product qualification rates and production efficiency. Some leading technologies have begun to deploy AI visual inspection systems and digital twin operation and maintenance models, further promoting the leap of equipment from "automation" to "intelligentization". In terms of greenization, equipment will focus on breaking through solid waste resource utilization technologies, widely adapting industrial wastes such as construction waste, fly ash, and slag as production raw materials, helping the construction industry realize resource recycling. Meanwhile, the application of servo hydraulic systems and low-energy consumption drive technologies will continuously reduce equipment energy consumption, in line with the concept of low-carbon production. In addition, the popularization of modular mold replacement technology will enhance equipment flexibility, enabling rapid adaptation to the production of blocks of different specifications and types to meet diversified construction needs.

The market pattern is showing new changes, with balanced regional development and accelerated localization replacement. From the perspective of regional distribution, the East China, South China, and North China regions remain the main consumer markets at present, accounting for more than 65% of the national total sales. However, guided by the new urbanization and rural revitalization strategies, the market penetration rate in the central and western regions is increasing at an annual rate of 15%, becoming a core potential area for future growth. Special support policies from local governments have further activated regional market vitality; policies such as equipment purchase subsidies and tax incentives have directly stimulated enterprises' purchasing willingness. In terms of market competition, domestic equipment has increased its market share to 72.6% by virtue of cost-effectiveness and localized service advantages, gradually narrowing the technological gap with international high-end brands. In the future, enterprises with core technology R&D capabilities and a complete service system will dominate the market pattern, and the industry concentration will be further improved.

Application scenarios continue to expand, empowering the diversified development of the construction industry. In addition to traditional ready-mixed concrete block production, the application proportion of fully automatic concrete block making machines in emerging scenarios such as prefabricated components for municipal engineering, ecological slope protection brick manufacturing, sponge city construction, and underground pipe gallery construction is rising rapidly, accounting for 28.4% in total by 2025. In the field of prefabricated buildings, high-precision blocks produced by these machines realize rapid construction without mortar masonry through technologies such as three-dimensional tenon connection, greatly improving construction efficiency and wall stability. In the rural revitalization scenario, environmentally friendly blocks produced by the equipment can meet the standardized needs of rural self-built houses, helping to improve the rural living environment. Furthermore, with the advancement of the "Belt and Road" Initiative, the upsurge in infrastructure construction in Southeast Asia, the Middle East, and Africa has provided broad space for the export of fully automatic concrete block making machines, becoming a new engine for industry growth.

Looking ahead, fully automatic concrete block making machines will continue to take technological innovation as the core driving force. Under the dual impetus of policy guidance and market demand, they will develop towards a more intelligent, greener, and more efficient direction. They will not only promote the transformation and upgrading of the building materials production industry, but also provide core equipment support for the construction industry to achieve green, low-carbon, and high-quality development, helping to build a more sustainable construction industry ecosystem.