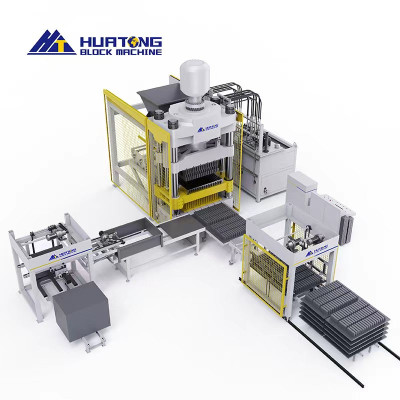

Automatic Concrete Block Machine

1.One Automatic Concrete Block Machine can produce a wide range of concrete blocks and bricks by changing molds.

2.Advanced vibration and guiding systems ensure accurate block dimensions, high density, and consistent product quality.

3.Modular structure, manual lifting system, and quick mold-change design minimize downtime and simplify maintenance.

4.Intelligent control with optimized vibration and hydraulic systems delivers fast, efficient, and eco-friendly block production.

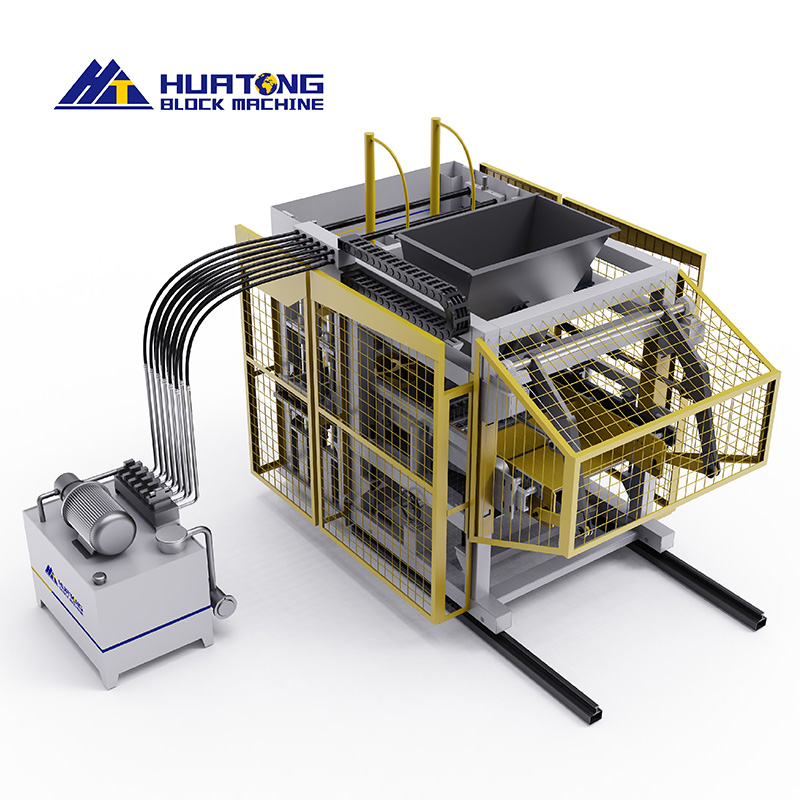

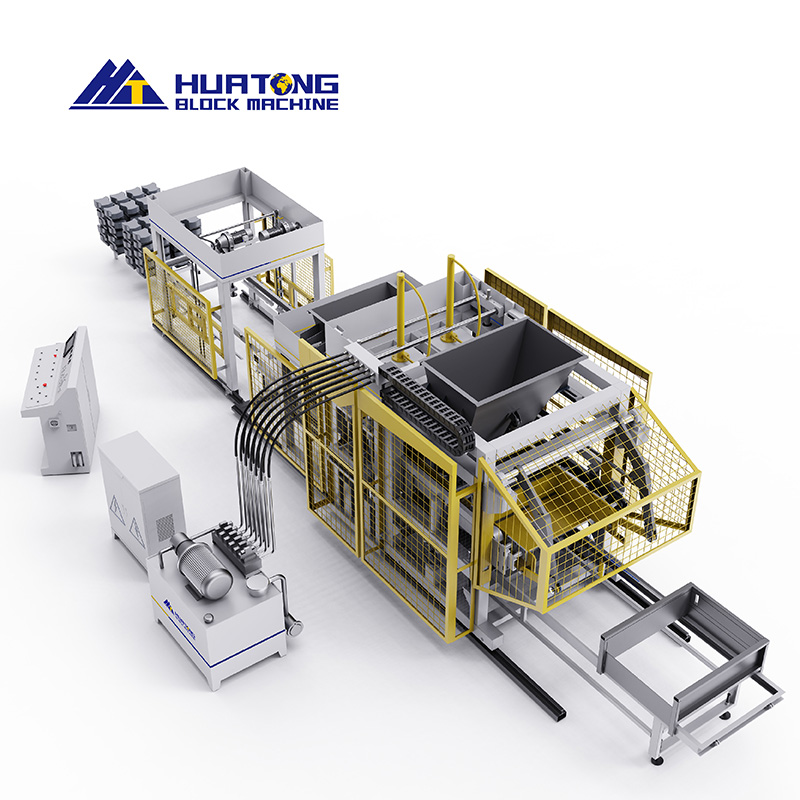

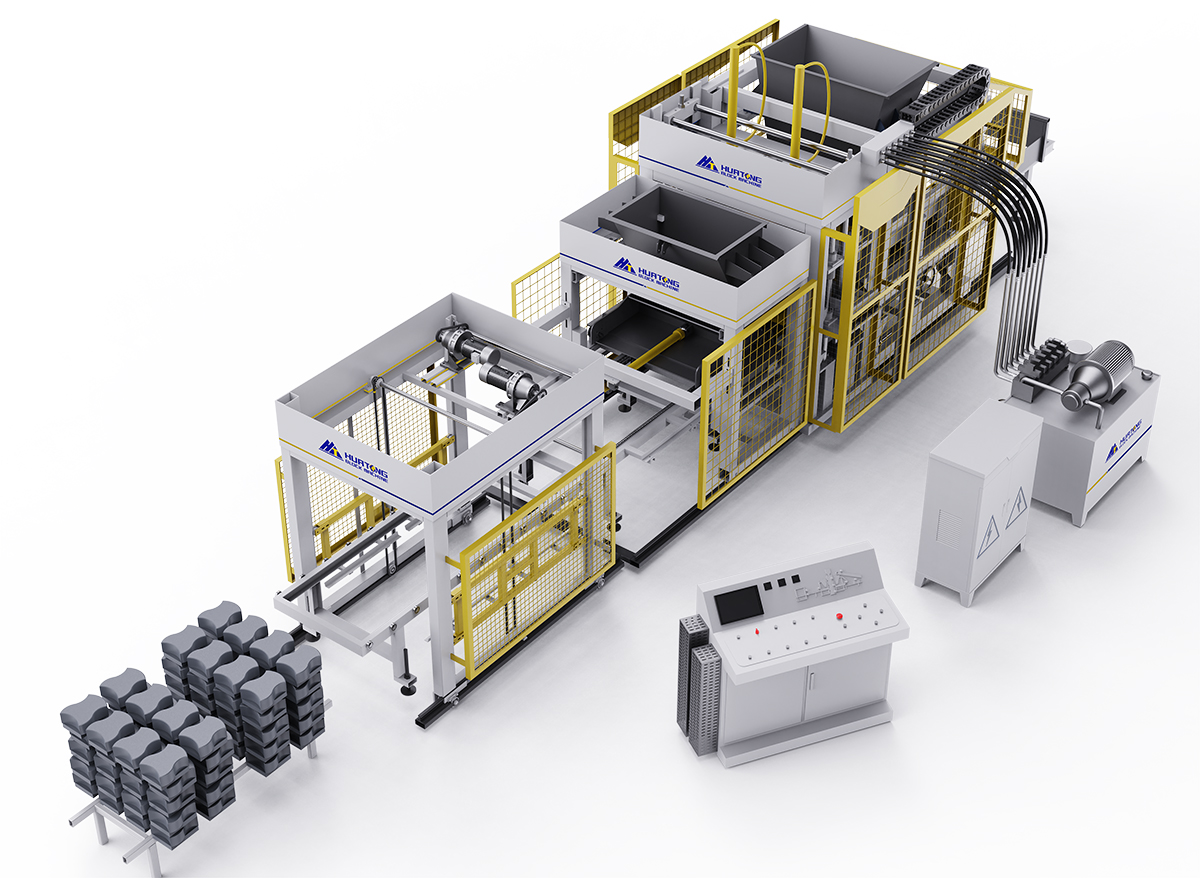

Automatic Concrete Block Machine is a high-efficiency multifunctional production line designed for manufacturing various types of concrete products, such as hollow blocks, solid bricks, walkway bricks, square paving bricks, curbstones, river slope protection blocks, dock bricks, and grass planting bricks. This model is QT10-15 and its pallet size is 1150x950mm.By simply changing the mold, it can flexibly produce different block types, achieving multi-purpose operation with one machine.The machine is good and suitable for large block making factory.

Production Capacity of QT10-15Automatic Concrete Block machine

Block Type | Picture | Size(L×W×H) | Pcs./ Pallet | Pcs./ Hour | Pcs./ 8Hours |

Hollow Block | 400x200x200mm | 10 | 1562 | 12500 | |

Hollow Block | 400x150x200mm | 12 | 1875 | 15000 | |

Hourdi Block | 200x100x60mm | 35 | 1250 | 43750 | |

Hollow Block | 530x160x195mm | 8 | 1250 | 10000 | |

| Stock Brick |  | 220x105x70mm | 39 | 7312 | 58500 |

We produce mould according to size and shape of client’s block. | |||||

Technical Parameter of QT10-15Automatic Concrete Block Making Machine

| Dimension | 5400x2050x3050mm | Weight | 17300KGS | |||

| Pallet Size | 1150x950mm | Performance Standard | JC/T920-2011 | |||

| Mode of Vibration | Table Vibration | Vibration Frequency | 4200r/min | |||

| Vibration Force | 90KN | Cycle Time | 15-25Sec. | |||

| Hydraulic Motor | 18.5kw-4P | Vibration Motor | 7.5kw-2P x2 | |||

| Concrete Feeder Motor | 4kw-23-4P | Belt Conveyor Motor | 2.2kw-43-4P | |||

| Wet Block Conveyor Motor | 1.5KW-35-4P | Stacker Motor | 1.5kw x2 | |||

| Power | 44.2kw | |||||

Product Advantages of QT10-15Automatic Concrete Block Making Machine

The vibration platform combines movement and stillness, reducing motor load during operation. This allows instant concrete liquefaction and gas release, resulting in standardized product dimensions. | |

Bioprintable arm-style double-bar fabric:The biomimetic arm-style double-bar fabric improves the fabricating speed and stability of the material cart, thereby reducing the occurrence of faults. | |

Extremely long guide sleeve design: The extremely long guide sleeve and the design featuring six guiding columns enhance the stability of the equipment's mold movement, resulting in more standardized finished product dimensions. | |

Hand-operated hydraulic jack lifting device: The hand-operated lifting device is more effortless, convenient, and quick when adjusting the height of the mold- changing device to regulate the fabric dispenser. | |

Modular assembly design:The modular assembly design allows the equipment to be separated during the replacement of molds and cleaning of the internal components, making the process of replacing molds and cleaning the equipment more convenient and efficient. | |

The main unit with an active mixer enables mandatory feeding and 360° rotation for fast, uniform distribution. Sealing devices prevent material leakage. The touchless switch is mounted on adjustable angular steel. |

Customer Case of QT10-15Automatic Concrete Block Making Machine

Benin | Russia |

Saudi Arabia | Djibouti |

Working Video of QT10-15Automatic Concrete Block Making Machine