Hydraulic Block Machine

Compared to the traditional method of producing bricks, the HT1000 static pressing brick machine has significant advantages in terms of production efficiency, energy consumption, quality, control difficulty, and ease of operation. For modern construction, using the HT1000 static press brick machine for brick production offers greater advantages and practical value, enhancing building quality, reducing production costs, and minimizing environmental pollution. It is a highly promising method of producing bricks.

Bricks are one of the essential materials in the field of construction. The traditional method of producing bricks has been in use for a long time. However, in recent years, with advancements in technology and innovation, a new production method has emerged – the Huatong HT1000 hydraulic brick machine.

Performance parameters:

| Working Pressure (KN) | 10000 |

| Pressing Quantity (pieces, standard bricks) | 45 |

| Pressing Cycle (seconds) | 15-20 |

| Pressing Property | Bidirectional Pressing |

| System Maximum Pressure (Mpa) | 31.5 |

| Mold Opening (mm) | 1340X1120 |

| Fly Ash Proportion (%) | 70 |

| Annual Production Capacity (pieces, standard bricks) | 60,000,000 |

| Annual Fly Ash Consumption (tons) | 110,000-120,000 |

| Total Installed Power (KW) | 105.4 |

| Weight (t) | 40 |

| Exhaust Times | More than 3 times (automatically adjustable) |

| Maximum Filling Depth (mm) | 360 |

Production parameter:

| Standard brick:240*115*53mm | |

| Quantity of each molding:48 Molding cycle:16-20S Production capacity:8600--10800/H |  |

| Cellular brick:240*115*90mm | |

| Quantity of each molding:24 Molding cycle:16--20S Production capacity:4300--5400/H |  |

| hollow brick:390*190*190mm | |

| Quantity of each molding:10 Molding cycle:16--20S Production capacity:1800--2200/H |  |

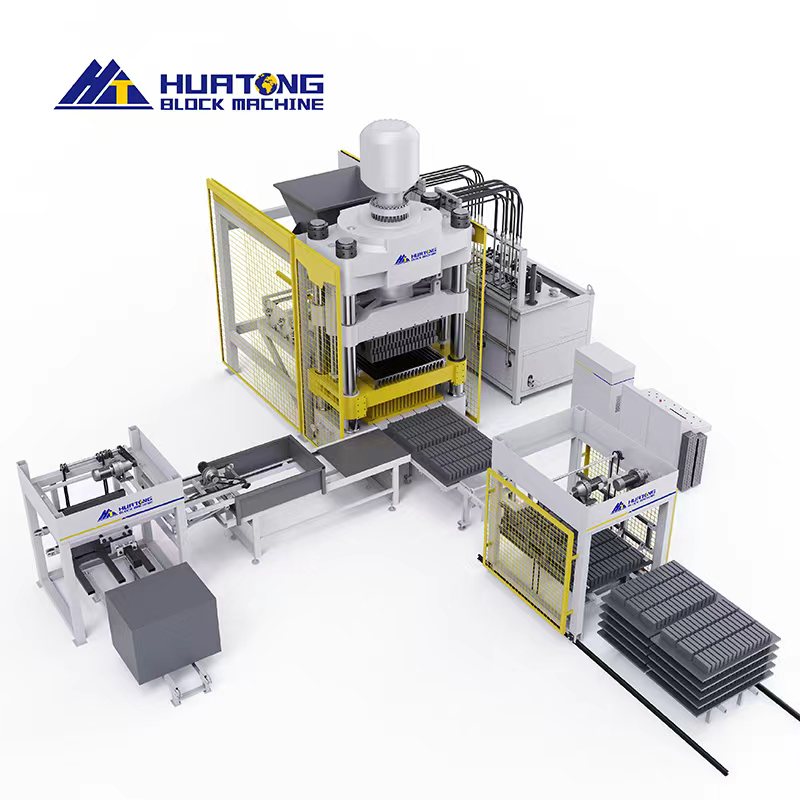

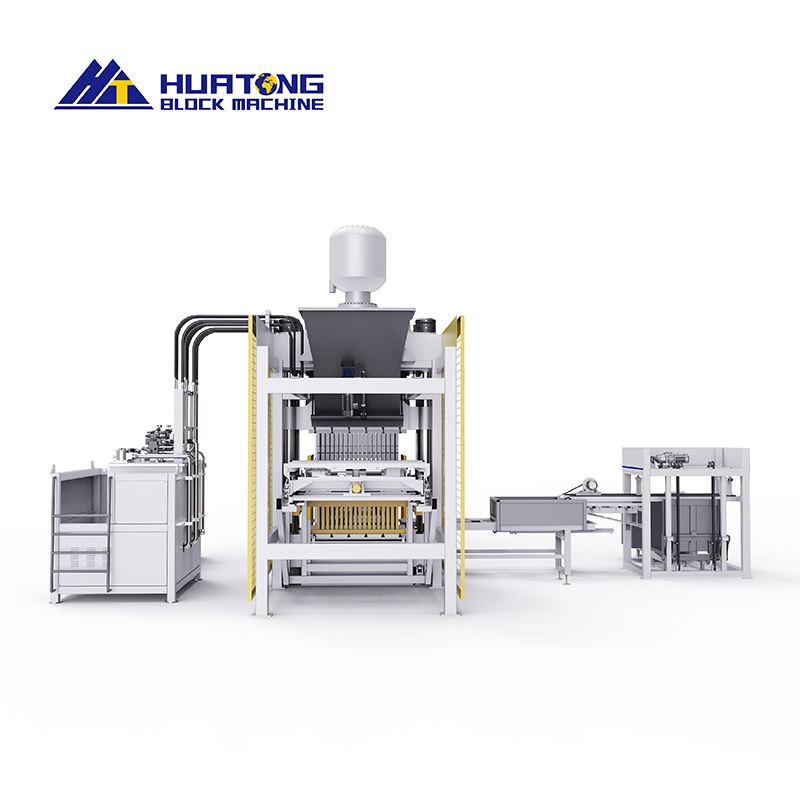

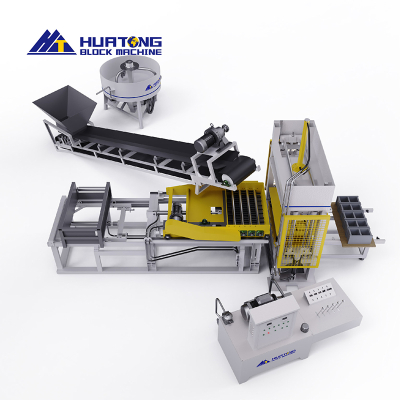

Equipment Production Site:

Product Details

1. Production Efficiency In terms of production efficiency, the HT1000 hydraulic brick machine has distinct advantages over traditional methods of producing bricks. The HT1000 hydraulic machine employs fully automated processes, enabling continuous production of bricks while also allowing for quick mold changes to accommodate different specifications of brick production. In contrast, traditional methods require extensive manual labor, resulting in lower efficiency and higher production costs. Additionally, with the HT1000 hydraulic machine, adjustments to pressure and vibration can be made to produce bricks with greater uniformity and higher strength, which is another aspect where traditional methods fall short.

2. Energy Consumption In terms of energy consumption, the HT1000 hydraulic brick machine also has significant advantages compared to traditional brick production methods. The HT1000 hydraulically driven brick machine employs fully automated production, automatic feeding, and automatic pressing, with all operations controlled by electronic devices. This results in minimal energy consumption. However, in traditional production methods, due to the need for extensive human labor and machinery, significant amounts of fuel and electricity are required, making the energy consumption considerably higher than that of the HT1000 hydraulic machine.

3. Quality Aspect In terms of the quality of bricks, the HT1000 type hydraulic brick machine also has significant advantages. The HT1000 type machine employs highly automated processes, utilizing extremely powerful vibrations during the pressing process. This results in more uniform pressure on the bricks, higher brick density, greater compactness, increased strength, and enhanced durability. Compared to traditional production methods, this results in significantly higher quality. Traditional production methods often lead to inconsistent quality, cracks, defects, and other issues, making it impossible to ensure that each brick meets the standards and to meet the demands of modern architecture. HT1000 type Hydraulic Brick Machine.

4. Difficulty of Control: In terms of difficulty of control, the HT1000 hydraulic brick machine is exceptionally impressive. The HT1000 hydraulically driven brick machine employs automated equipment for brick production, allowing for automatic control and adjustment through computer programs. Additionally, it is user-friendly, with a visualized production process, enabling parameters such as brick pressure and vibration to be easily modified at any time. This ensures better control over the overall quality of the bricks. In contrast, the traditional production method’s difficulty of control arises from the need for extensive manual labor, resulting in greater operational and control complexities, with numerous human factors contributing to instability in quality control.

5. Simplicity of Operation: In terms of simplicity of operation, the HT1000 hydraulic brick machine also holds an advantage. The HT1000 hydraulically driven brick machine is fully automated, requiring no complex operations. Once the parameters are set, the production of bricks can begin. The operation is simple and convenient, with a memory function that allows it to retain production parameters. In contrast, traditional production methods are not only complex but also require collaboration among multiple individuals to complete the work. Manual operations are prone to errors, leading to longer production cycles and increased costs.

In summary, compared to traditional methods of producing bricks, the HT1000 hydraulic brick machine manufactured by Huatong possesses significant advantages in terms of production efficiency, energy consumption, quality, control difficulty, and ease of operation. For modern construction, using the HT1000 type hydraulic brick machine for brick production offers greater advantages and practical value, enhancing building quality, reducing production costs, and minimizing environmental pollution. It is a highly promising method of producing bricks.

FAQ

1. What regular maintenance is needed?

Clean molds daily to prevent residue buildup; lubricate pressure cylinders weekly; inspect hydraulic lines monthly for leaks.

2. How long do key components last?

Molds endure 80,000-150,000 cycles; hydraulic systems last 5-8 years with proper care; pressure plates need replacement every 2-3 years.

3. Can operators handle minor repairs?

Yes, tasks like replacing seals or cleaning filters are manageable; major issues (e.g., cylinder leaks) require professional technicians.

4. How to prevent pressure system failures?

Use recommended hydraulic oil, keep oil clean, and avoid overloading the machine—this extends the pressure system’s lifespan.