Automatic Brick+Making+Machine

The Automatic Brick+Making+Machine adopts four galvanized pipe with sleeve bearing to ensure the exact movement of mould.Gear and shaft balance system of automatic brick+making+machine can make male and female mould move stably.Concrete feeding is revolving,convective and compulsive to ensure block density and reduce feeding cycle. Feeder moving is two curved arms drived by two cylinders,which makes feeder move quickly,durably,and steady.

1.The Automatic Brick+Making+Machine Mould had been heat treatment,processing quenching,tempering,carbonization and boriding.It makes the mould working life more strong and longer.

2.The Automatic Brick+Making+Machine Hydraulic System adopts Proportion Direction Valve.The Valve can adjust flow rate and buffer cylinder during the process of block making production.Therefore,Proportion Direction Valve can protect cylinder and extend life,and Improve the speed and flexibility of each part of the Automatic Brick+Making+Machine.

3.The Vibration System of Automatic Brick+Making+Machine adopts German Frequency Conversion Technology.The vibration motor is Frequency Conversion Controlled.The lubrication of Vibrator adopts oil immersed,it will improve the using life of Bearing and Gear of the vibrator.

4.Adopting International Advanced Microcomputer Control Technology to make Automatic Brick+Making+Machine and electrical equipments to be one part.The Automatic Brick+Making+Machine Plant can work automatically and cyclically.Huatong technicians put fault diagnosis,problem alarming into computer by safty logic control.The screen will timely and accurately show fault and methods to clients if the machine is in error.

Produc Parameters of Automatic Brick+Making+Machine:

| Standard | JC/T920-2003 | |

| Vibration Frequency | 4500 r/min | |

| Vibration Pressure | 90KN | |

| Motor Specifications | Vibration Motor(kw) | 7.5*2 |

| Concrete Feeder Motor(kw) | 4.0 | |

| Hydraulic System Motor(kw) | 18.5 | |

| Belt Conveyor Motor(kw) | 2.2 | |

| Stacker Motor (kw) | 1.5*2 | |

| Wet Block Conveyor Motor | 1.5 | |

| Production/mould | Hollow block(390x190x190mm) 10Pics/mould | |

| Solid brick (240×115×53 mm) 48 Pics/mould | ||

| paver brick(200×100×60mm)36 Pics/mould | ||

| Cycle Time | 15-25seconds | |

| Hollow block (390×190×190 mm) 12000-17000Pics | ||

| Production/day(8hours) | ||

| Solid brick (240×115×53mm) 90000-100000Pics | ||

| Paver brick (200×100×60 mm) 51000Pics | ||

| Motor Power | 44.2Kw | |

| Water Consumption | 5-10T | |

| Number of workers | 7-10worker | |

| Space of Ground | 6600 square meters | |

| Gross Weight | 16T | |

| Machine Dimension | 5400×2050×3050mm | |

| Main materials | Cement,crushed stone dust,gravel,sand,coal fly ash,iron/aluminium dust,crushed cinder and some industrial wastes | |

| Products of machine | Hollow blocks,Solid bricks,Pavers,Kurbstones,Slope blocks,slabs, interlock bricks and so on. | |

Capacity of Automatic Brick+Making+Machine:

| Block Type | Picture | Size(L x W x H) | PCS./Pallet | PCS./Hour | PCS./8 Hours |

| Hollow Block |  | 400x200x200mm | 10 | 1562 | 12500 |

| Hollow Block |  | 400x150x200mm | 12 | 1875 | 15000 |

| Hourdi Block |  | 530x160x195mm | 8 | 1250 | 10000 |

| Stock Brick |  | 220x105x70mm | 40 | 7500 | 60000 |

| Paving Block |  | 200x100x60mm | 35 | 5468 | 43750 |

| Paving Block |  | 225x112.5x60mm | 24 | 3450 | 27600 |

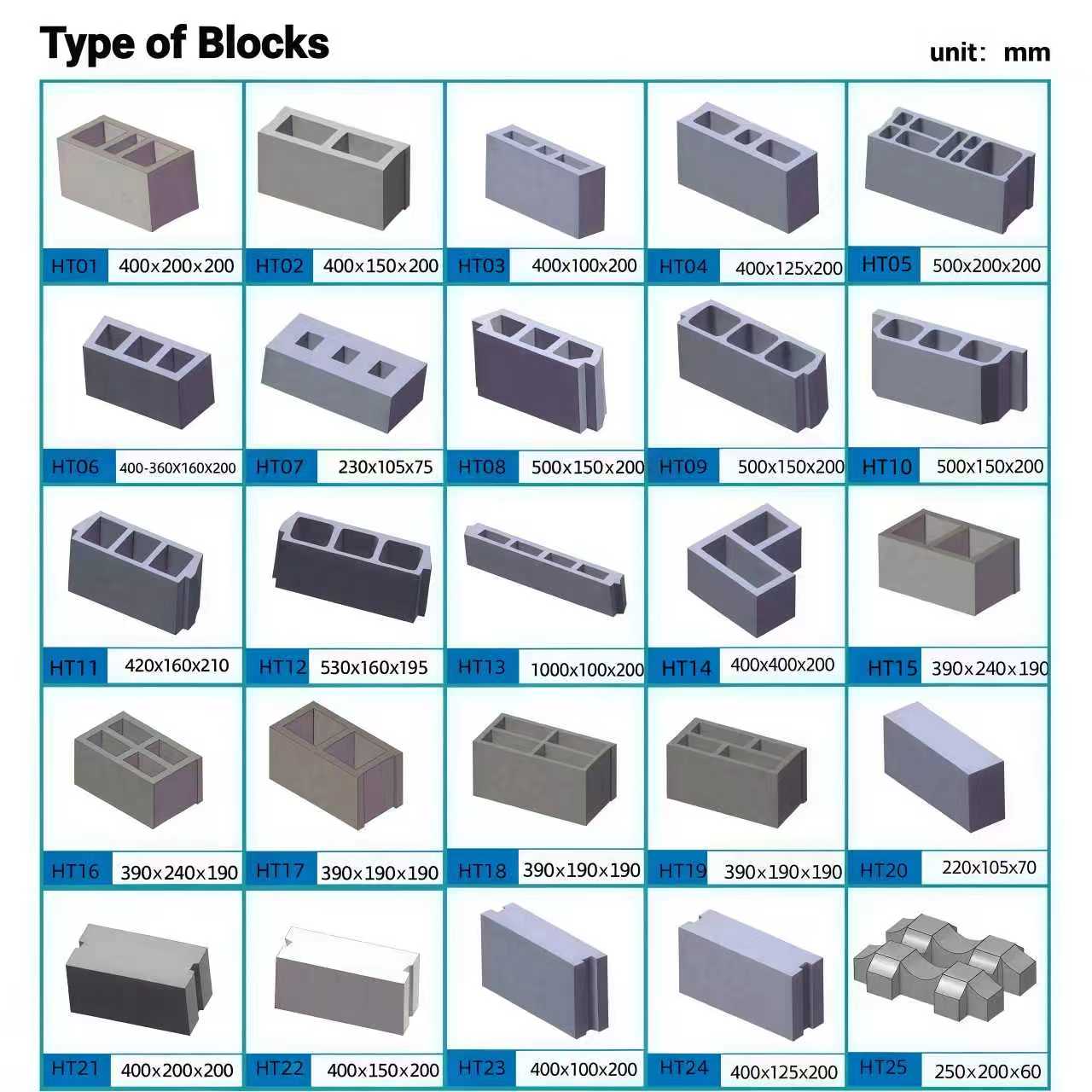

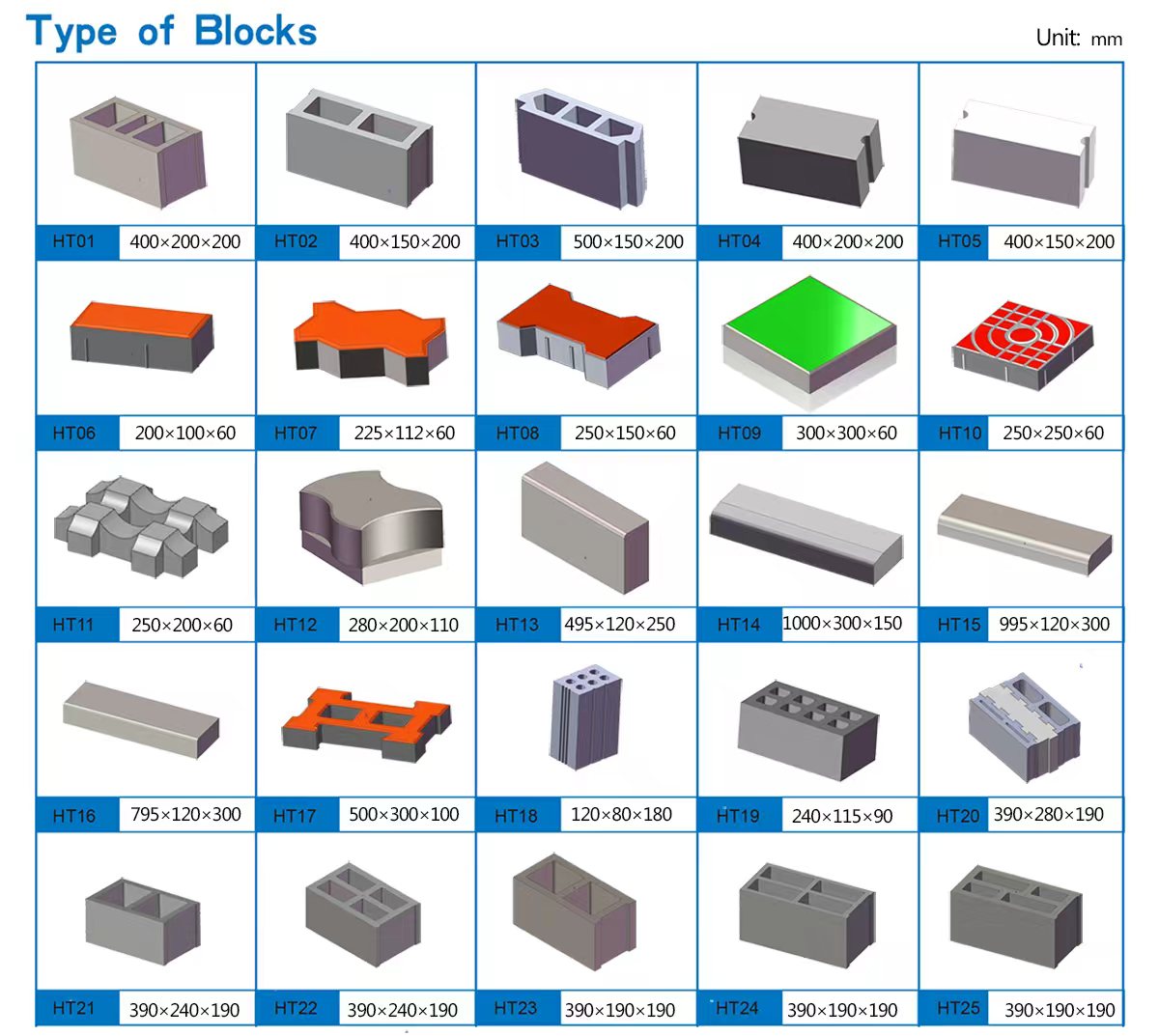

Block sample:

1,Hollow blocks:For high building,house,villa,wall and so on.

2,Solid blocks:For high building,house,villa,wall,park,road and so on.

3,Paving blocks:For park,road,invironment grow grass so on.

4,Interlocking blocks:For park,garden,road,house decoration and so on.

5,Curb stone:road side.

Packing and Loading:

The whole block making machine line could load in two full 40'HC containers.

We can load the block making machine to your countries nearest port,then you can let your forwarder to clear custom and transport to your place,its easy to operate,if you needed,we will send our technician to your place to guide installation and training workers.

Befor sale service:

1,We will supply the block making machine specification.

2,Show how to operate the machine.

3,Could supply the block samples disign drawing.

4,Tell our customer the international business operation procedure.

5,24h E-mail and call service.

After Sale service:

1,Our technician is available to overseas service,guide installation and help training the workers.

2,24h E-mail and call service.

3,One year guarantee time.