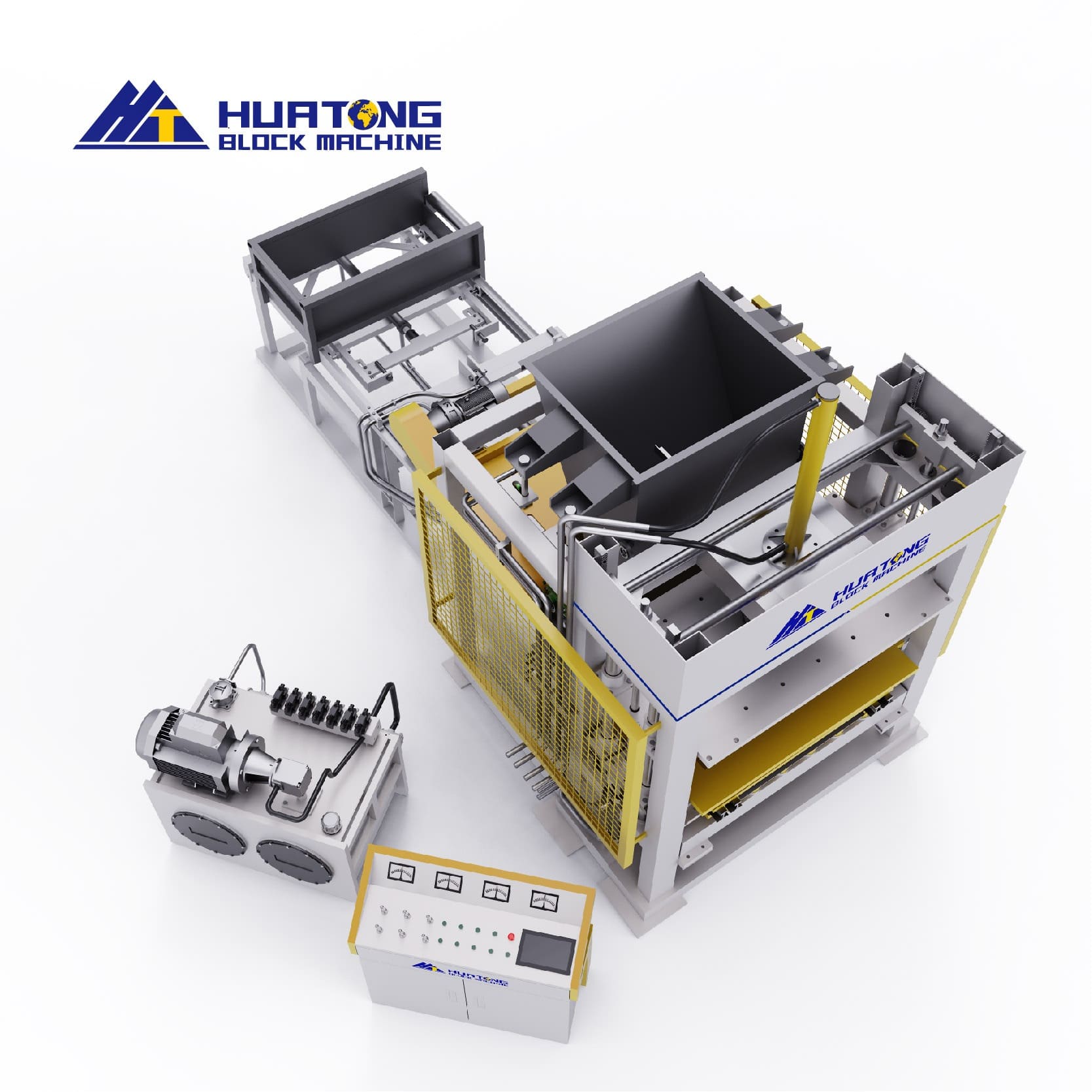

Brick Making Machine Sale

Model:QT5-15

The fully automatic QT5-15 type non-fired brick machine features numerous advanced functions, incorporating a dual-balance design that effectively prevents mold jamming issues.

The fabric car lift platform utilizes a hoist to facilitate convenient lifting, thereby simplifying the process of changing molds while ensuring both aesthetic appeal and practicality in production. Regarding the vibration system, this machine incorporates Germany’s most advanced vibration technology. The vibration unit and the vibration platform are designed as a single unit, combining static and dynamic platforms to achieve penetrating vibration. It features high vibration frequencies and variable frequency vibration capabilities. This significantly enhances material uniformity and production stability, reducing the occurrence of faults.

The QT5-15 is a compact model designed for small to medium-scale block production. The fabric car lift platform utilizes a hoist to facilitate convenient lifting, thereby simplifying the process of changing molds while ensuring both aesthetic appeal and practicality in production. Regarding the vibration system, this machine incorporates Germany’s most advanced vibration technology. The vibration unit and the vibration platform are designed as a single unit, combining static and dynamic platforms to achieve penetrating vibration. It features high vibration frequencies and variable frequency vibration capabilities. This significantly enhances material uniformity and production stability, reducing the occurrence of faults.

Technical Parameters of QT5-15Automatic Concrete Block Making Machine

Dimension | 3000x1900x2930mm | Weight | 10000KGS |

Pallet Size | 1150x580mm | Performace Standard | JC/T920-2011 |

Mode of Vibration | Table Vibration | Vibration Frequency | 4200r/min |

Vibration Force | 70KN | Cycle Time | 15-25Seconds |

Hydraulic Motor | 15KW-4P | Vibration Motor | 2x5.5kw-2P |

Concrete feeder Motor | 4KW-23-4P | Belt Conveyor Motor | 3KW-6P |

Wet Block Conveyor Motor | 1.5kw-35-4p | Mobile Stacker Motor | 2x1.5kw |

Total Power | 37.5KW | HS Code | 8474809090 |

Production Capacity of QT5-15Automatic Block Making Machine

Product Type | Image | Size (mm) | Per Molding | Cycle Time | Daily Output (8 hrs) |

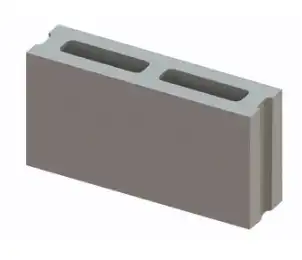

Hollow Block | 400×200×200 | 5 pcs | 15–20 s | 7200–9600 pcs | |

Hollow Block | 400×150×200 | 6 pcs | 15–20 s | 8640–11500pcs | |

Hollow Block | 400×100×200 | 9 pcs | 15–20 s | 12960–17280pcs | |

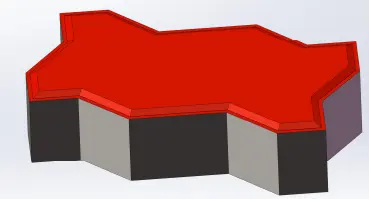

Paving Brick | 200×100×60 | 20 pcs | 20–25 s | 23000–38400pcs | |

Paving Brick | 225×112.5×60 | 16 pcs | 20–25 s | 18400–30700pcs |

Product Details of QT5-15Automatic Concrete Block Making Machine

1. Utilizing professional electro-control technology and reliable hydraulic systems, the machine integrates mechanical, electrical, hydraulic, and integrated automatic control functions. It is easy to operate and reliable to run.

2. Utilize specialized dual-end synthesis output vibration technology to optimize the placement of vibration units, ensuring that the excitation force is evenly distributed within the vibration table.

3. The mold pressing and vibration system allows the concrete to fully liquefy and release air within two to three seconds, ensuring high compactness of the product. This is particularly suitable for producing high-strength standard bricks, as the formed bricks can be stacked immediately, eliminating the need for extensive investment in pallets.

4. The combination of specialized vibration technology and a device for breaking up obstructions enables separate control of the vibration for fabric distribution and shaping, resulting in the most uniform distribution and shaping of the fabric.

5. High adaptability and versatility; it can be used for multiple purposes. It is not only suitable for producing concrete blocks, but also for producing blocks made from fly ash, furnace slag, mineral waste, etc. By installing different molds, it can produce various types of blocks, such as reinforced blocks, standard bricks, hollow bricks, and porous bricks, in different sizes.

Customer Case of QT5-15Automatic Block Making Machine

Myanmar | Tanzania |

Vietnam | Azerbajan |

Working Video of QT5-15Automatic Block Making Machine