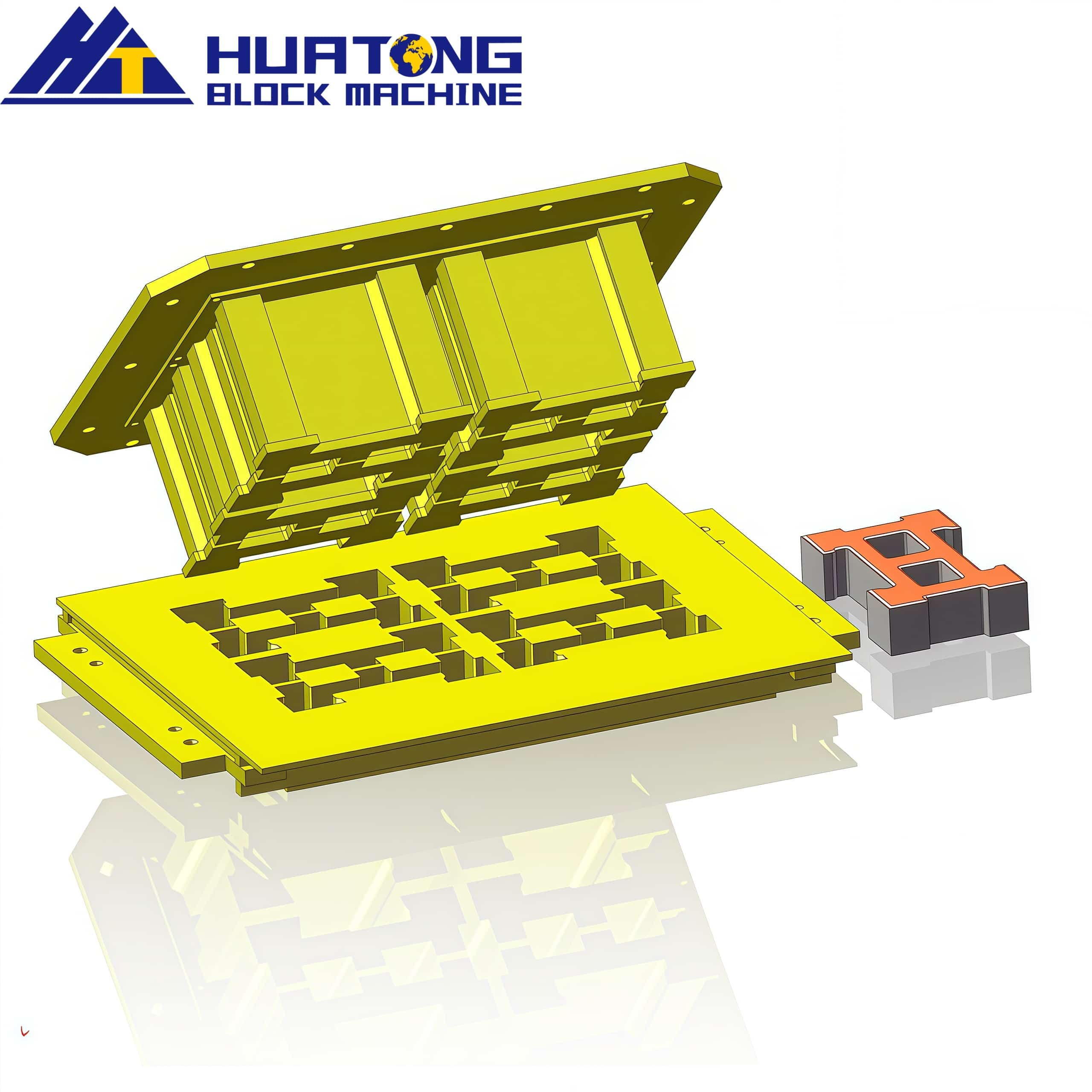

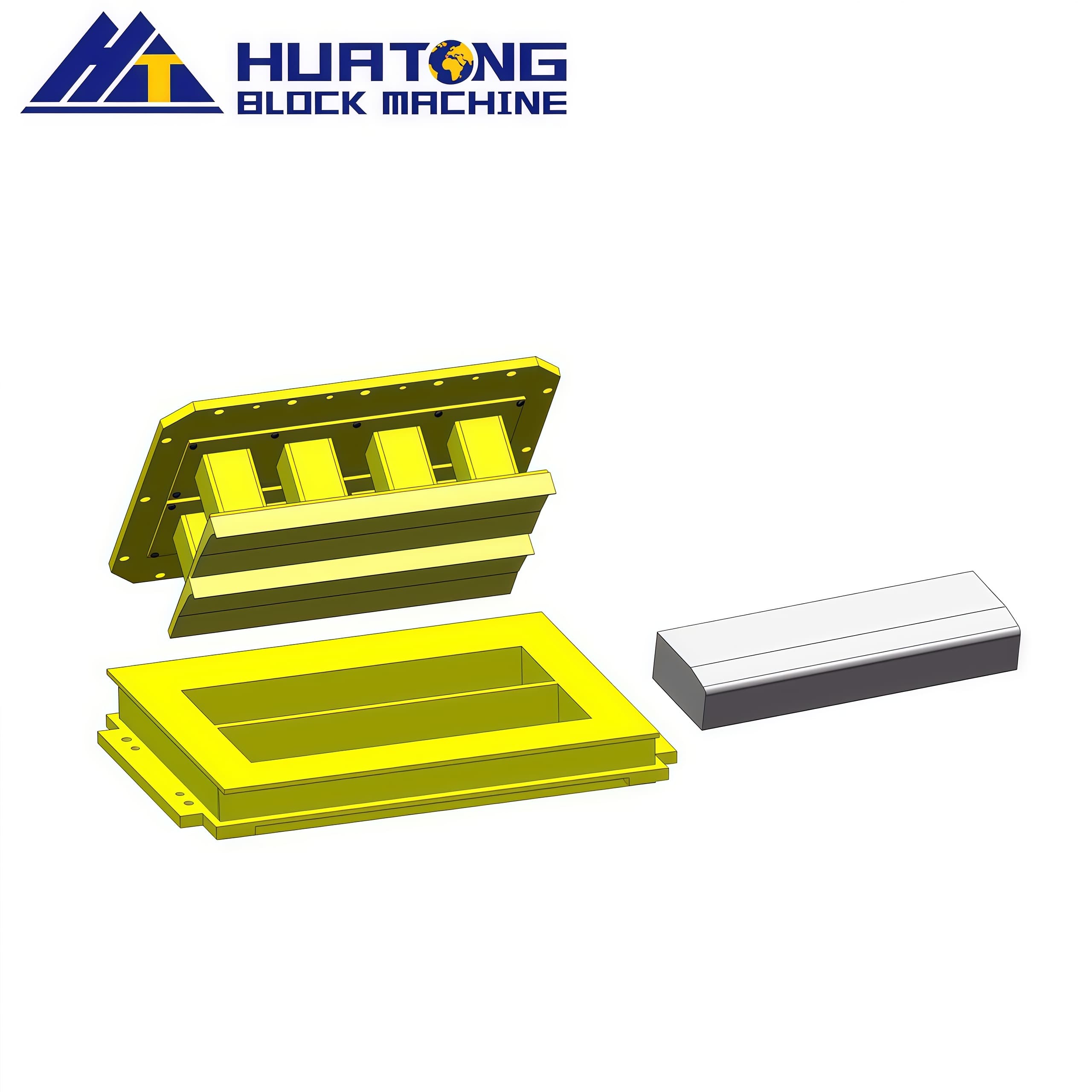

Brick Making Mould

In riverbank protection projects, the use of trapezoidal slope blocks plays a crucial role. In addition to trapezoidal slope blocks, there are other options such as chain-link slope blocks and lock-type slope blocks. These molds are designed to fully meet the requirements of construction projects. Furthermore, to facilitate the removal of the molds, there is typically no hollow structure within the inner walls of the trapezoidal slope block templates, which distinguishes them from other chain-link slope mold products.

Shandong Huatong Brick Making Mould Workshop can design and customize moulds according to different needs.

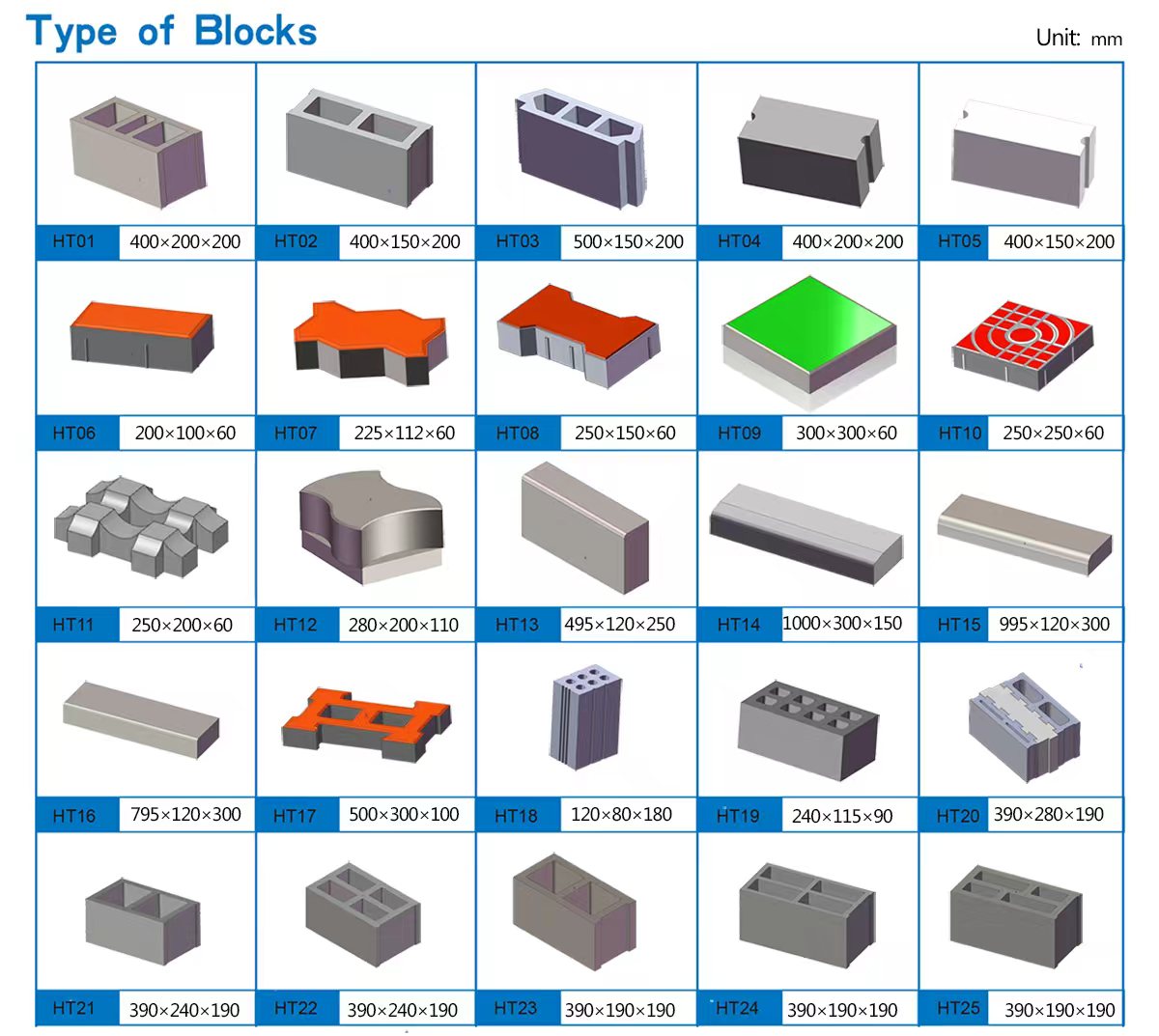

Before selecting the mold specifications, we need to have a thorough understanding of the molds. For example, the production ratios of irrigation cross-slope mold, the selection of riverbank cross-slope mold, the uses of road cross-slope mold, and the rapid production of highway hexagonal block mold. These factors all impact the choice and effectiveness of the molds.

Brick Making Mould five big advantage:

1) Using national standard steel, small difference, super wear-resistant.

2) The precision is micron level, and the mold can be customized according to customer requirements;

3) Adopt intelligent robot welding to ensure perfect welding and excellent performance.

4) The self-developed automatic heat treatment technology makes the structure stronger and the service life can reach more than 100000 times.

5) The mold base is perfectly matched with the pressure head, and has the characteristics of low loss, fast feeding, and stable demoulding;

| Excellent Selection of materials,retaining wall brick machine mold raw material steel selection of national standard steel. High power laser cutting equipment to ensure cutting accuracy. |

Retaining wall brick machine mold have powerful mould machining center,in the industry's processing capacity in the forefront,every year in high-precision CNC Equipment investment is huge. |  |

| Has a vacuum carburizing furnace,the whole retaining wall brick machine mold carburizing time needs740 minutes,can make the mould more hard and more durable,and can use long times. |

Our brick making mould had exported to over 30 countries since 2004. such as Lybia,Niger,Cameroon,Guinea,

Liberia,Uganda,Zimbabwe,South Africa,Botswana,Saudi Arabic,Tanzania,Kenya,Zambia,

Malawi,Ghana,Namibia,Tanga,DR Congo,Benin,Djibouti,Sudan,Mozambique,Algeria,Nigeria,Russia and so on.

In the analysis of the process for the “L”-shaped retaining wall molds, we need to pay attention to the durability, precision, and production efficiency of the molds. These factors directly affect the progress and quality of the project.

Overall, selecting the right mold is crucial to the success of riverbank protection projects. We need to choose the most suitable mold type and specifications based on actual needs to ensure the smooth progression of the project.

Frequently Asked Questions:

1,Are you a famous brand in block making machine mould industry?

Yes,we are top 5 supplier in China .

2,What can you do if I do not familiar with the block mould?

We have block sample for you to choose from,or you can share with us block picture,then we follow your picture to design moulds.