Automatic Block Machine

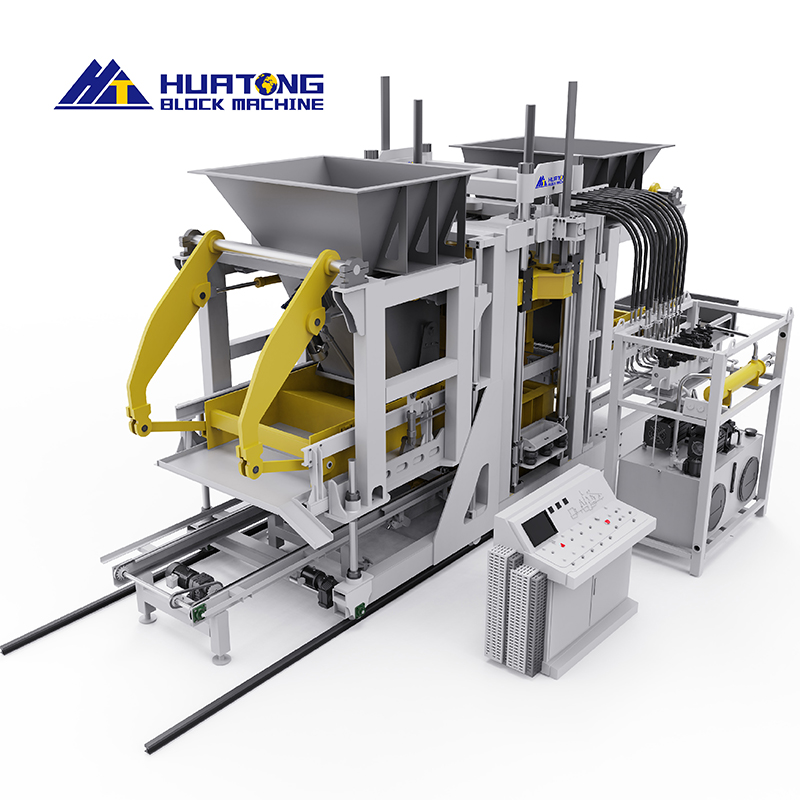

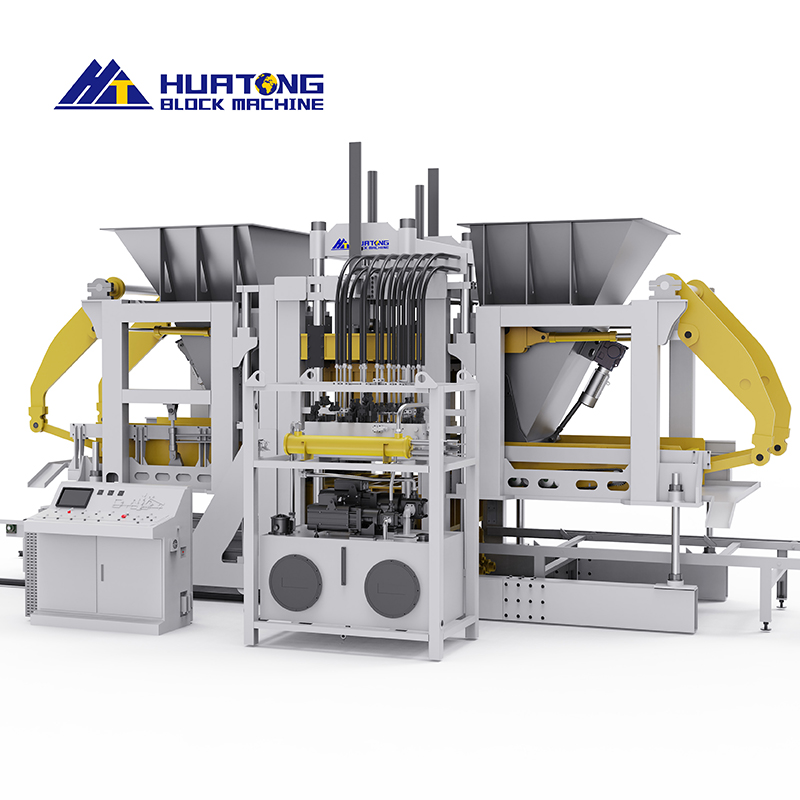

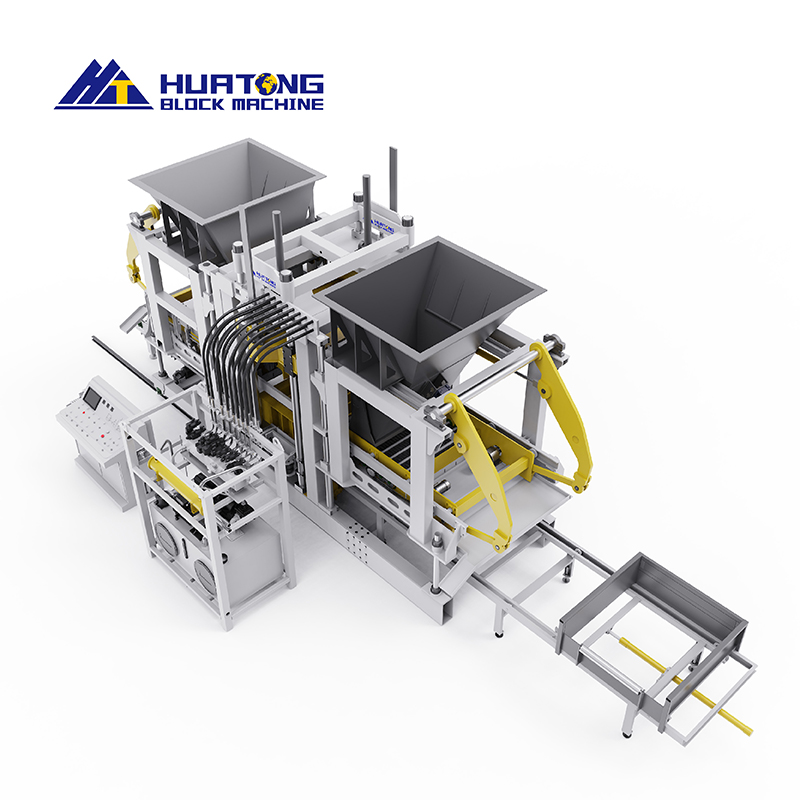

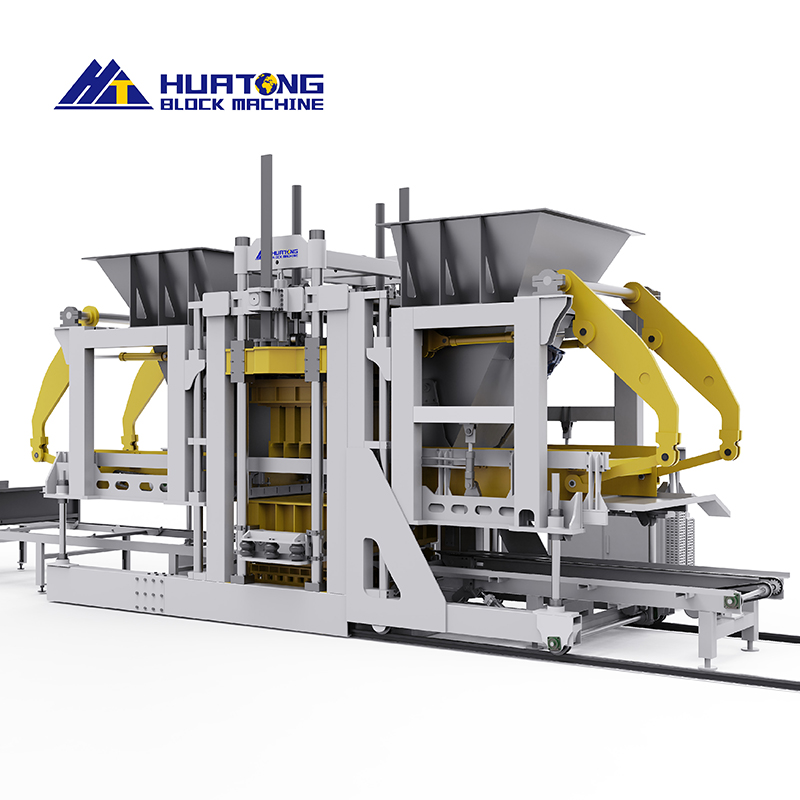

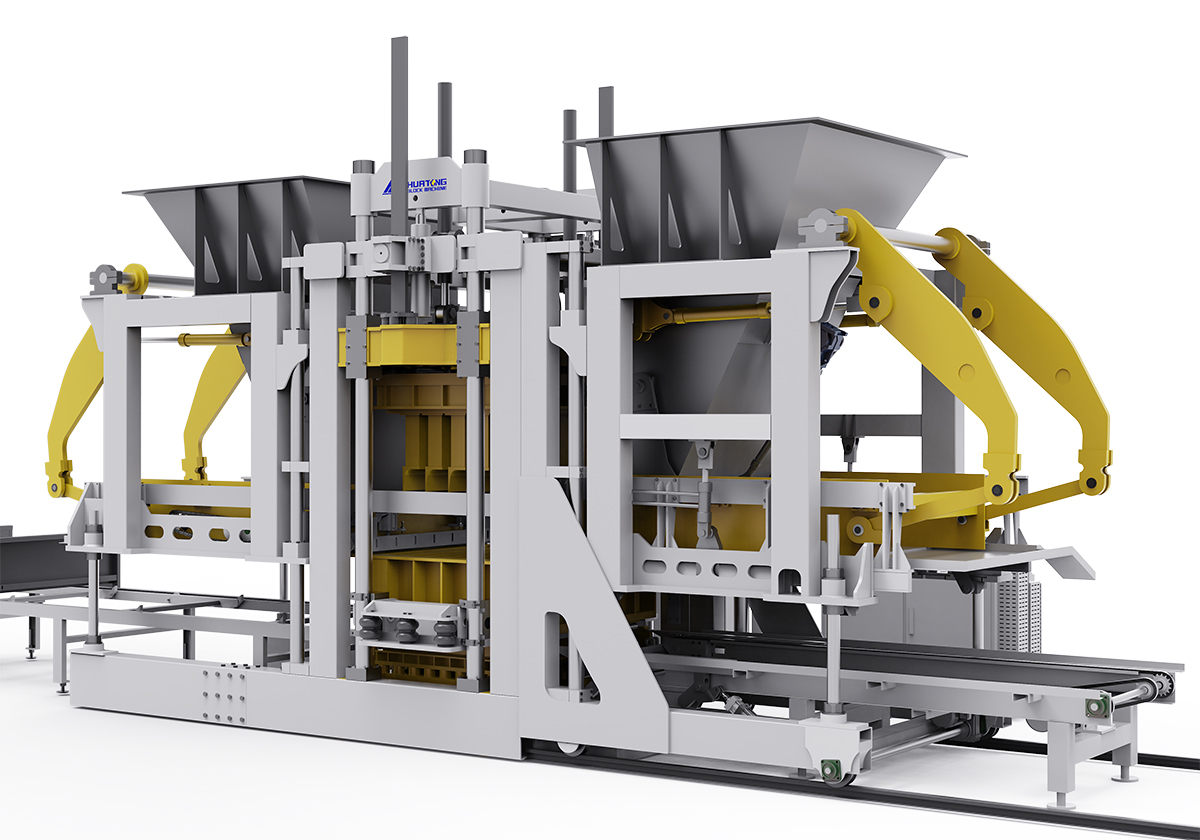

QT18-15 Automatic Block Machine Adops Sophisticated design:

Automatic Block machine balance system adopts the 4 rod guide method, and the ultra-long guide sleeve ensures the precise movement of the pressure head and the mold box.

The rack adjustment system improves the balance and coordination between the pressure head and the mold box in the production process. Rotary convection and compulsory cloth mode ensure the density of bricks, shorten the cloth time, and the gear transmission mode is more stable.

QT18-15 automatic block machine is the 1 kind of mechanical equipment that completes the whole process of raw material mixing, pressing molding, automatic demoulding, conveying and maintenance through an automatic system to realize efficient and standardized production of bricks. The automatic block machine core advantage is to greatly reduce manual intervention and improve production efficiency.

Automatic Block Machine Technical Parameters:

| Dimension | 5000*2800*4500mm |

| Mode of Vibration | Table Vibration |

| Pallet Size | 1400*1400*30-40mm |

| Rated Pressure | 21Mpa |

| Oil Station Power | 22KW |

| Cycle Time | 15-20'S |

| Mould Rockwell Hardness(HRC) | ≥55 |

| Application Category | Construction industry: production of concrete hollow blocks, solid bricks, etc. |

| Raw Material | Cement, sand and gravel, stone powder, stone nitrate, slag, slag and other building materials |

Production Capacity of QT18-15 Automatic Block Machine:

| Block Type | Picture | Size(L x W x H) | Pcs./Pallet | Cycle Time | Pcs./8 Hours |

| Hollow Block |  | 400x200x200mm | 18 | 15-20's | 25900-34500 |

| Hollow Block |  | 400x150x200mm | 24 | 15-20's | 34500-46000 |

| Hollow Block |  | 400x100x200mm | 33 | 15-20's | 47500-63300 |

| Paving Block |  | 200x100x60mm | 66 | 20-25's | 76000-95000 |

| Paving Block |  | 225x112.5x60mm | 45 | 20-25's | 51800-64800 |

Automatic Block Machine Performance and Characteristics:

1,Sophisticated design: Automatic block machine balance system adopts the 4 rod guide method, and the ultra-long guide sleeve ensures the precise movement of the pressure head and the mold box. The rack adjustment system of automatic block machine improves the balance and coordination between the pressure head and the mold box in the production process. Rotary convection and compulsory cloth mode ensure the density of bricks, shorten the cloth time, and the gear transmission mode is more stable. Automatic block machine walking style of the double-bar crank arm increases the speed of the fabric, showing durability and stability. The frequency conversion technology of the stacking machine has the advantages of speed control, intelligent adjustment of the speed of the cycle, smooth starting, speed coordination, and flexible operation.

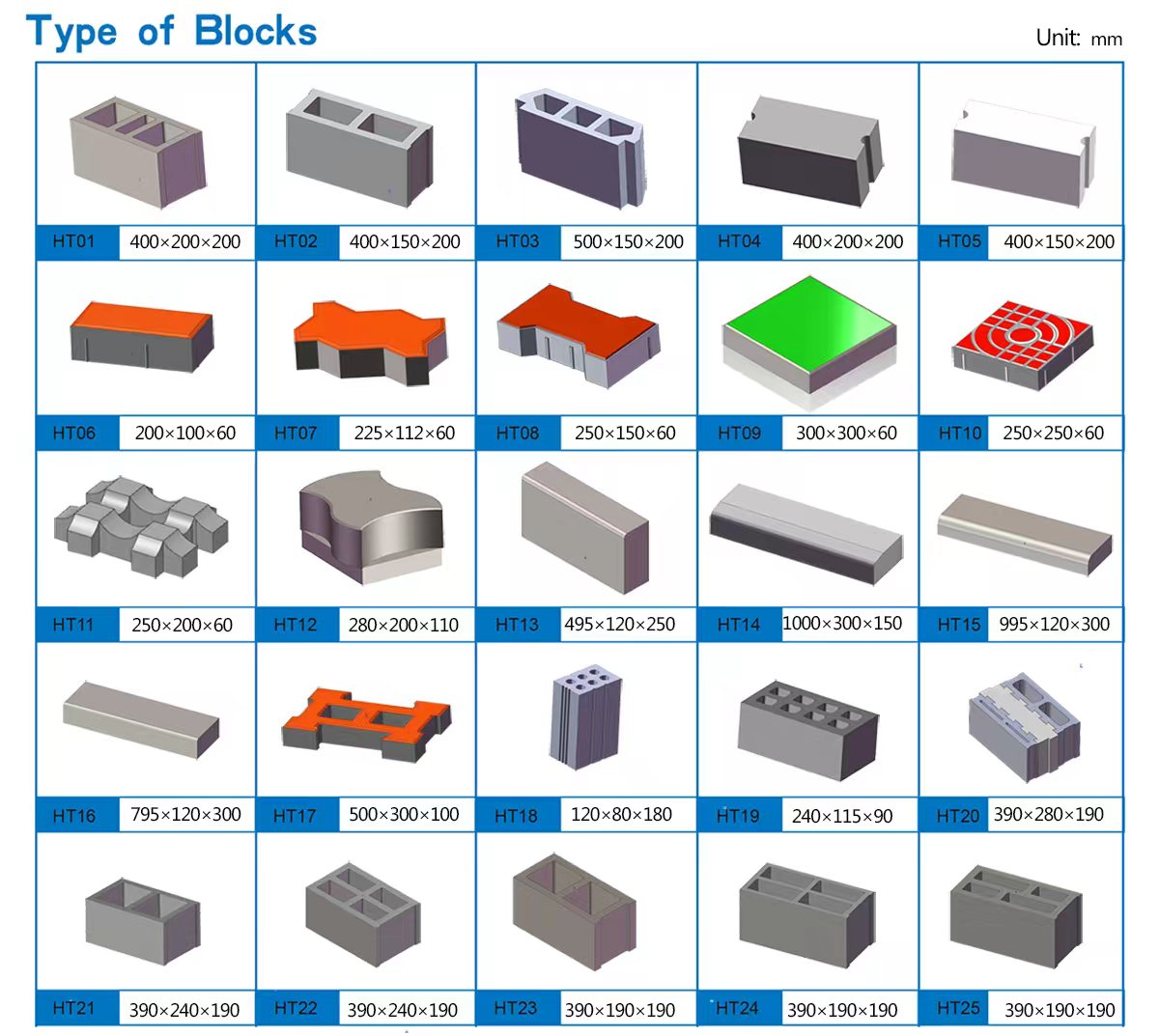

All our machine can produce different blocks by changinging moulds,such as hollow,paving,solid,interlocking,kerbstone and so on.

Block sample:

Automatic Block Machine Loading and Packing:

Loading professional, safety first, space optimization, according to the size of the goods to plan the stacking method, priority: heavy goods and then down, light goods on the top, large goods bottom, small goods fill gaps, reduce space waste.

About our company:

Shandong Huatong Hydraulic Machinery Co., Ltd. (hereinafter referred to as "Shandong Huatong") was founded in 2004 and is located in Gaotang, Shandong Province. It is a scientific and technological enterprise focusing on the design, research and development, production and sales of bulk industrial solid waste comprehensive utilization equipment. It has intelligent production line of automatic block forming machine, automatic static pressure forming machine production line, high-precision assembled gypsum block production line, aerated concrete block production line, vertical shaft planetary mixing station and other products, and waste scheme customization, preparation and operation services. It has member enterprises such as Huatong Machinery, Avante Machinery, Darun Environmental Protection, Cote d'Ivoire Shandong Group Company, and more than 270 engineers and technicians of all kinds.