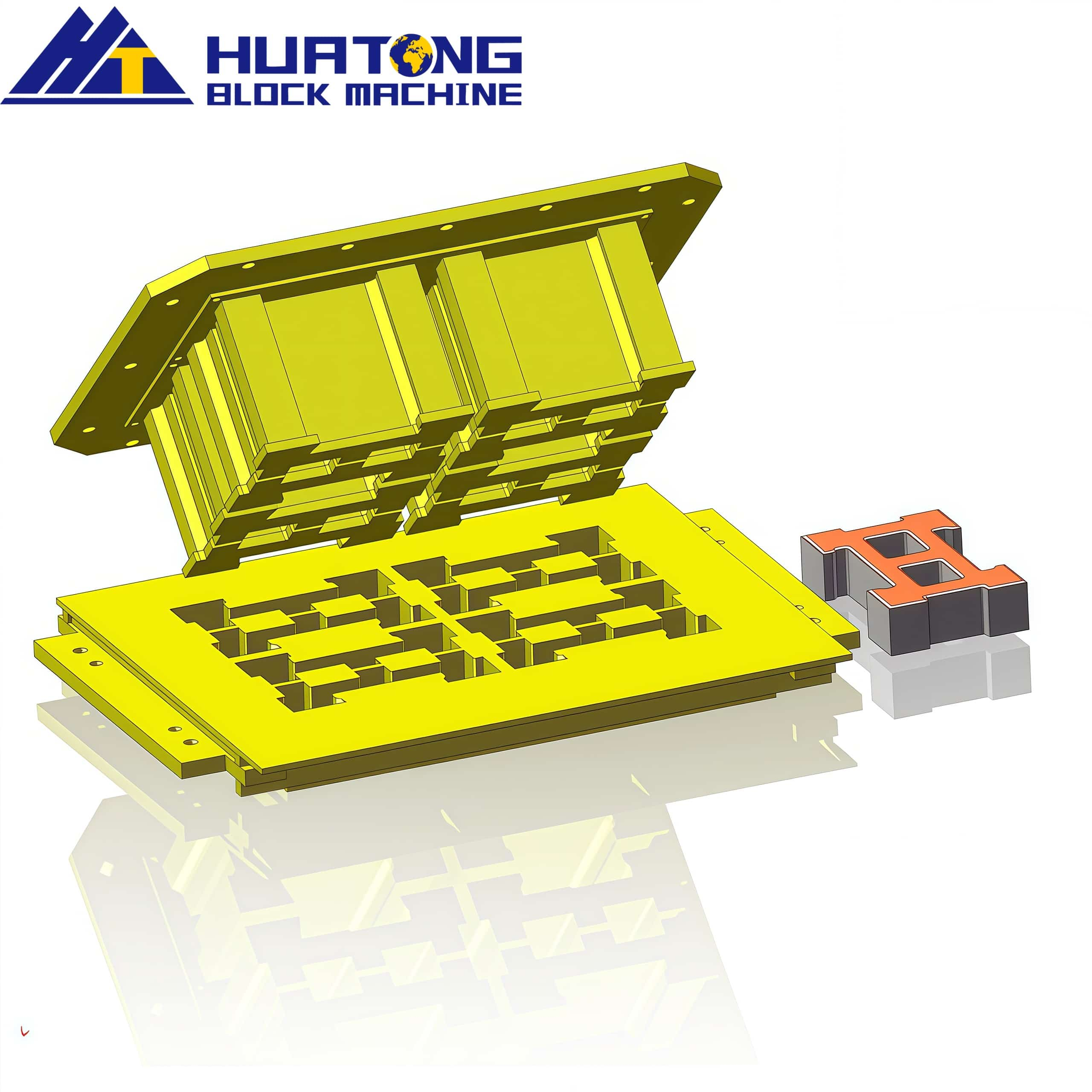

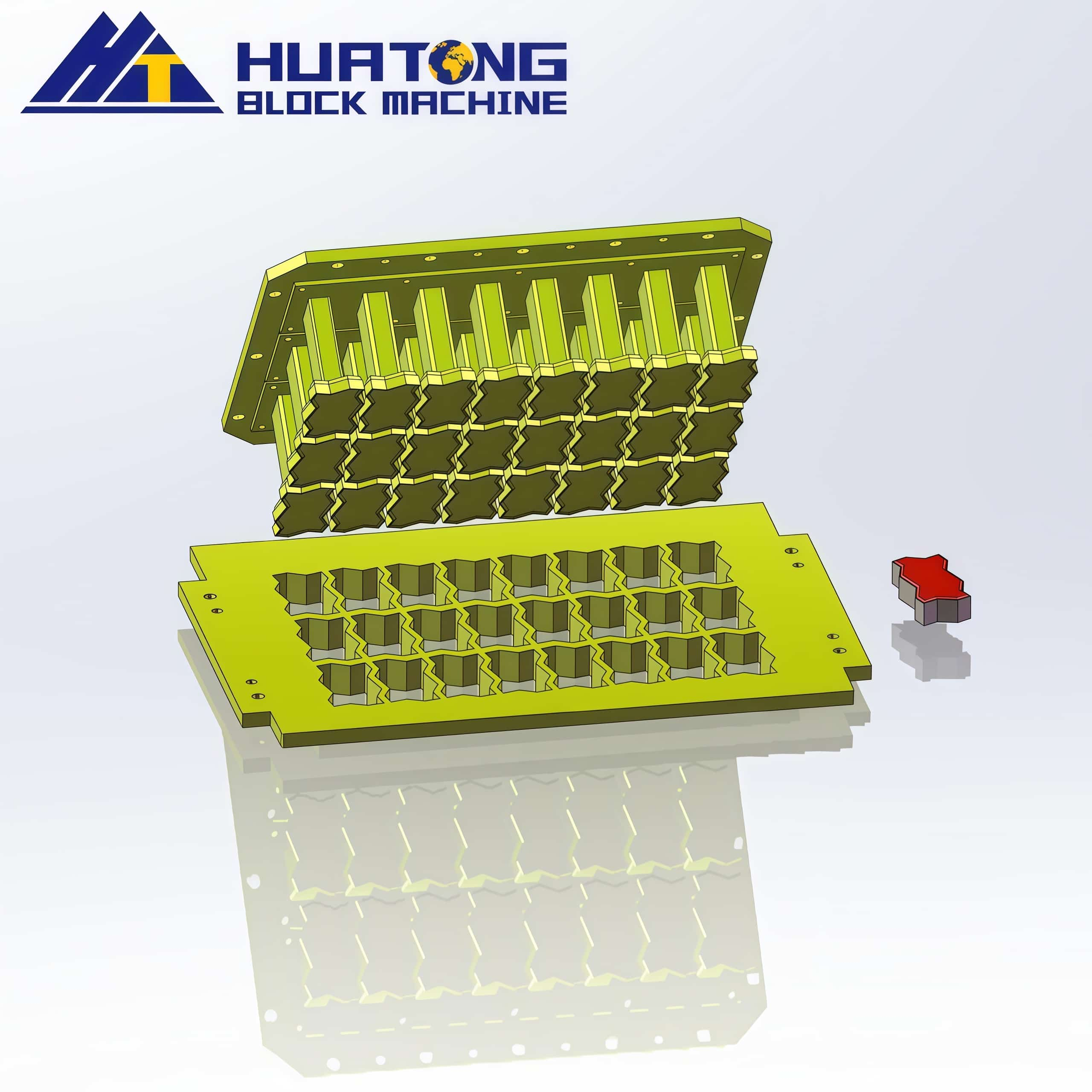

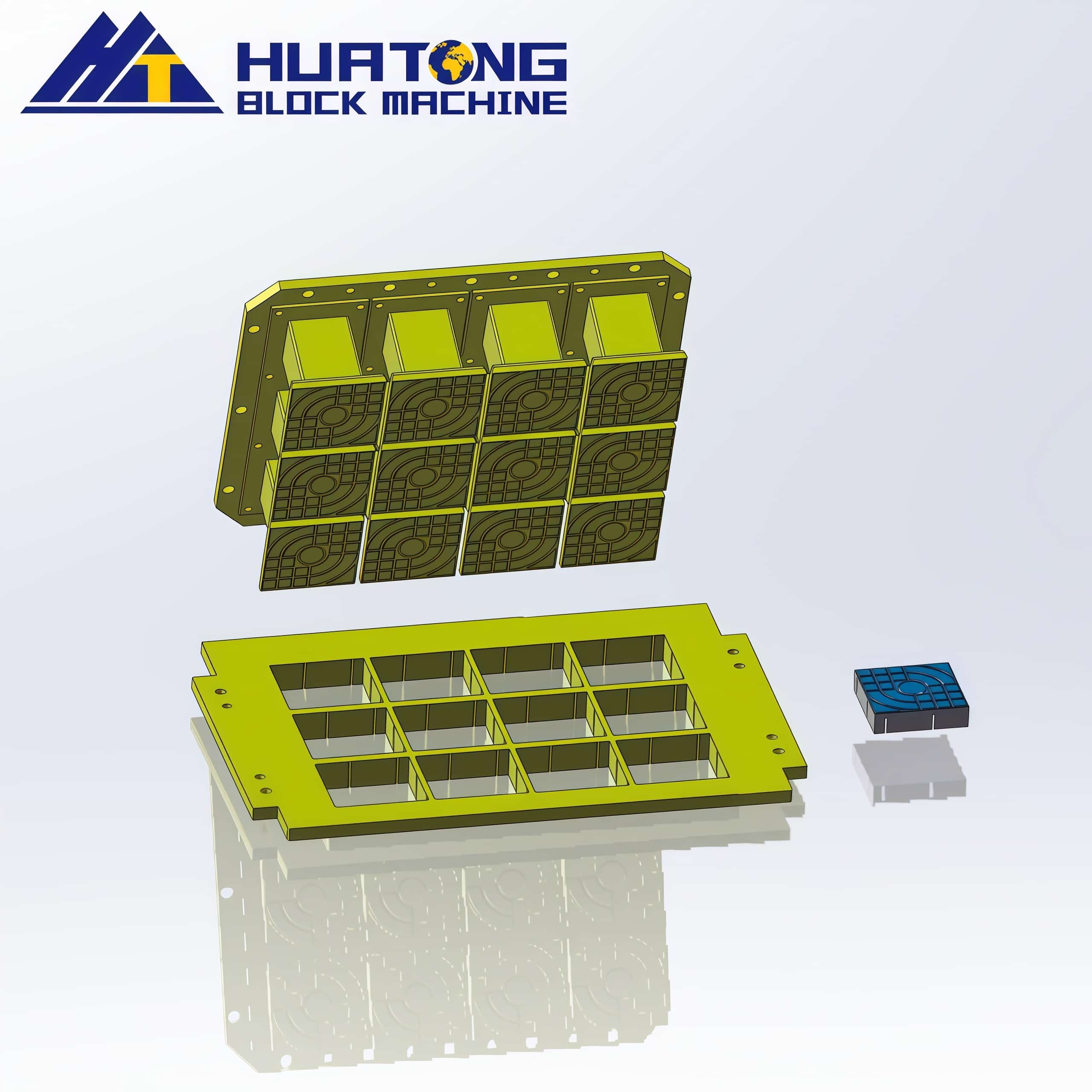

Hollow Mold

Hollow mold are designed for the different efficient production of durable, high-quality hollow bricks. The hollow mold ensure that each blocks is consistent in good size and shapes, making the blocks ideal for a variety of construction projects.

Hollow mold provide uniform results, minimize waste and optimize material use. The hollow block mold are durable, require minimal maintenance, and provide long-term performance.

Shandong Huatong Hollow Mold Workshop can design and customize moulds according to different needs. We have a complete set of processing machines, heat treatment machines and specially developed molds and assembly equipment. The hollow mold undergoes carburizing, boronizing and heat treatment processes to ensure hollow mold processing accuracy, assembly accuracy, hardness and wear resistance of the plate indenter and frame, and matching accuracy between the frame and the plate, so as to produce a smooth surface and precise size Concrete products.

Process Description of hollow mold:

The hollow mold use excellent selection of materials, raw material steel selection of national standard steel. High power laser cutting equipment to ensure cutting accuracy |

Powerful hollow mold machining center, in the industry's processing capacity in the forefront, every year in high-precision CNC equipment investment is huge. |

Has a vacuum carburizing furnace, The whole hollow mold carburizing time needs 740 minutes Can make the construction hollow block mold hardness between 62-68 degrees |

We had many customers over the world,such as Pakistan,Kazakhstan,South Africa,Botswana,Tanzania,Kenya,Zambia,

Malawi,Ghana,Namibia,Tanga,DR Congo,Benin,Djibouti,Sudan,Mozambique,Algeria,Nigeria,Russia and so on.

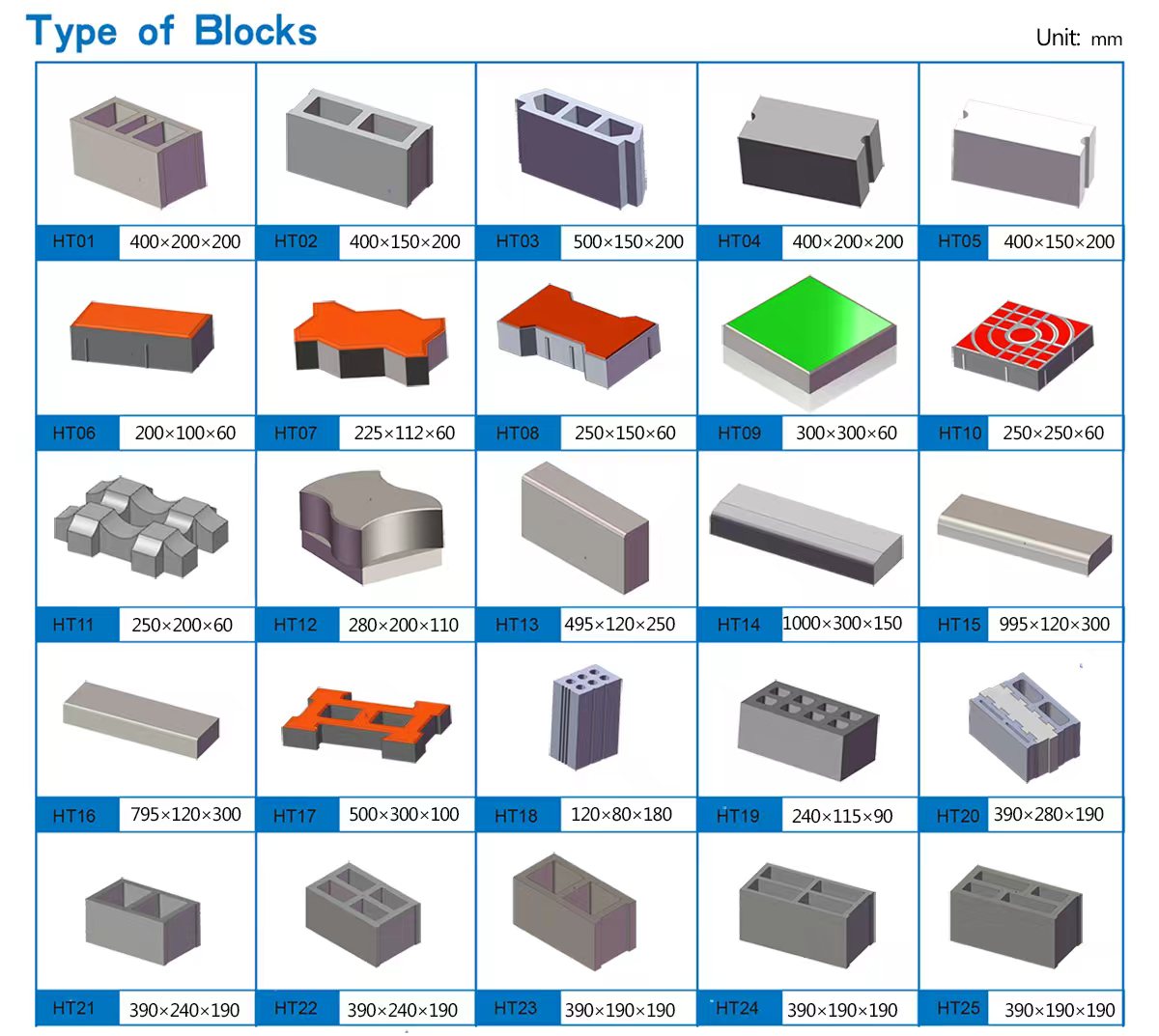

The well-designed hollow mold can work well with Huatong brick making machine to produce various high-quality concrete products, such as concrete blocks, paving stones, hollow blocks, solid bricks, curbs and some special sizes and shapes of blocks/bricks.

FAQ:

1,Why your price is not cheap than others?

Because our mould adopts a variety of heat treatment processes such as quenching, tempering, carburizing, and nitriding, which greatly enhances the wear resistance of the mold, thereby increasing the life of the mold.

2,How can I know I choose your mould is right?

We,Shandong Gaotang Huatong Hydraulic Pressure Machinery Co.,Ltd. Is a famous block making machine manufacture since 2004,our machine and mould had exported to over 30 countries in the world.Choose us,you can get the best quality mould you want,and it will make your business more better.

3,Do you test all the moulds before delivery?

Yes,we test all our products before delivery.

4,What is the payment method?

30% payment as deposit,70% balance pay before arrange delivery.

Shandong Huatong Hydraulic Machinery Co., Ltd. (hereinafter referred to as "Shandong Huatong") was founded in 2004 and is located in Gaotang, Shandong Province. It is a scientific and technological enterprise focusing on the design, research and development, production and sales of bulk industrial solid waste comprehensive utilization equipment. It has intelligent production line of automatic block forming machine, automatic static pressure forming machine production line, high-precision assembled gypsum block production line, aerated concrete block production line, vertical shaft planetary mixing station and other products, and waste scheme customization, preparation and operation services. It has member enterprises such as Huatong Machinery, Avante Machinery, Darun Environmental Protection, Cote d'Ivoire Shandong Group Company, and more than 270 engineers and technicians of all kinds.