Brick Blocks Making Machine

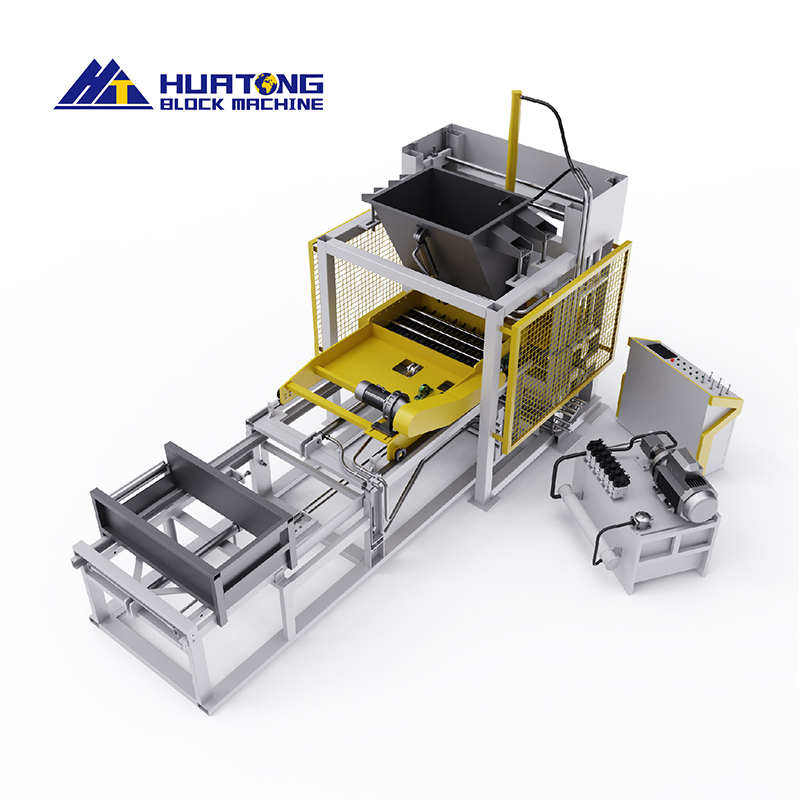

Model: QT10-15A

Advantages of QT10-15A Brick Blocks Making Machine

1. Durable Core Components

Molds: Multi-stage heat treatment (quenching/tempering/carburizing) enhances hardness and wear resistance, reducing long-term replacement costs.

Vibration System: Oil-immersed exciter design improves lubrication and heat dissipation, doubling bearing life.

Hydraulic System: Imported high-dynamic proportional valves enable precise control, automatic flow regulation, and cylinder protection.

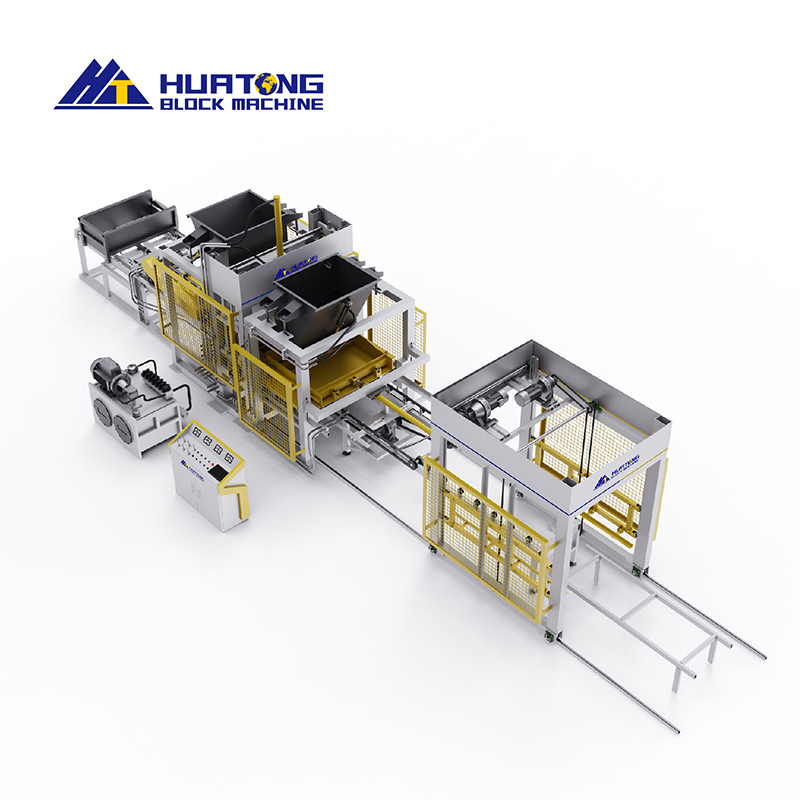

2. Premium Quality & Versatility

Produces high-density, dimensionally accurate products with excellent surface finish.

Quick mold switching enables production of over 100 material types (standard bricks, hollow blocks, paving stones, etc.).

Allows flexible adaptation to market demands with a single machine.

Technical Specifications of Our Automated Brick Production Machinery

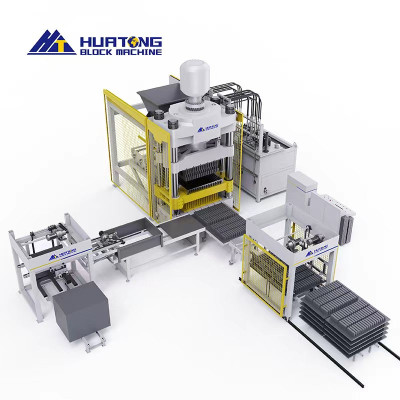

1. Superior Operational Performance with Exceptional Cost Efficiency

This advanced model represents a significant evolution of the QT10-15A platform, achieving an optimal equilibrium between production efficiency, output quality, and operational stability. The machinery delivers production capabilities and automation levels comparable to large-scale industrial lines, while maintaining a highly competitive acquisition cost - thereby enabling investors to achieve maximized returns with minimized capital expenditure.

The system maintains an efficient production cycle of 12-15 seconds per mold plate, yielding a daily production capacity of several tens of thousands of standard bricks. Notably, it requires substantially lower initial investment, reduced operational footprint, and diminished energy consumption compared to conventional large-scale production systems,

thereby providing mid-scale investors with unparalleled competitive leverage in the marketplace.

2. Intelligent Automation with Human-Centric Engineering

Transcending conventional automation paradigms, our system incorporates sophisticated intelligent control technologies. The architecture integrates advanced Programmable Logic Controller systems with precision electrical components sourced from internationally recognized manufacturers (including German and Japanese partners), enabling comprehensive functionality including single-command operation, automated fault diagnostics, and remote performance monitoring.

Operation is facilitated through an intuitive color touchscreen interface, allowing complete parameter configuration and real-time system monitoring. The integrated diagnostic system provides immediate visual alerts through textual and coded displays that precisely identify fault locations and recommend appropriate corrective procedures, substantially reducing operational complexity and maintenance requirements.

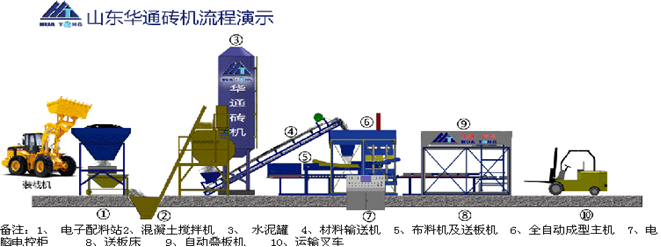

1 Electronic batching station 2 Concrete mixer 3 Cement tank 4 Material conveyor 5 Placing machine and plate feeder 6 Fully automatic molding host 7 Computer control cabinet 8 Plate feeder 9 Automatic plate stacking machine 10 Transport forklift

Technical parameters of QT10-15 fully automatic non-fired brick machine

Host power | 48.5KW | Exciting force | 100KN | |

Machine quality | 14T | Mold Rockwell hardness | ≥55 degrees | |

Dimensions | 5400x2050x3050mm | Pallet size | 1150*900*25mm | |

Molding cycle | 13-18 seconds/time | power distribution | 120KW | |

Production capacity | 36million units /year | Implementation standards | JC/T920-2011 | |

(240*115*53mm) |

National quality certification

Logistics delivery guarantee

Shandong HuaTong Hydraulic Machinery Co., Ltd. (hereinafter referred to as "Shandong Huatong") was founded in 2004 and is located in Gaotang, Shandong Province. It is a scientific and technological enterprise focusing on the design, research and development, production and sales of bulk industrial solid waste comprehensive utilization equipment. It has intelligent production line of automatic block forming machine, automatic static pressure forming machine production line, high-precision assembled gypsum block production line, aerated concrete block production line, vertical shaft planetary mixing station and other products, and waste scheme customization, preparation and operation services. It has member enterprises such as Huatong Machinery, Avante Machinery, Darun Environmental Protection, Cote d'Ivoire Shandong Group Company, and more than 270 engineers and technicians of all kinds.