Cement Brick Machine

Model: QT4-15

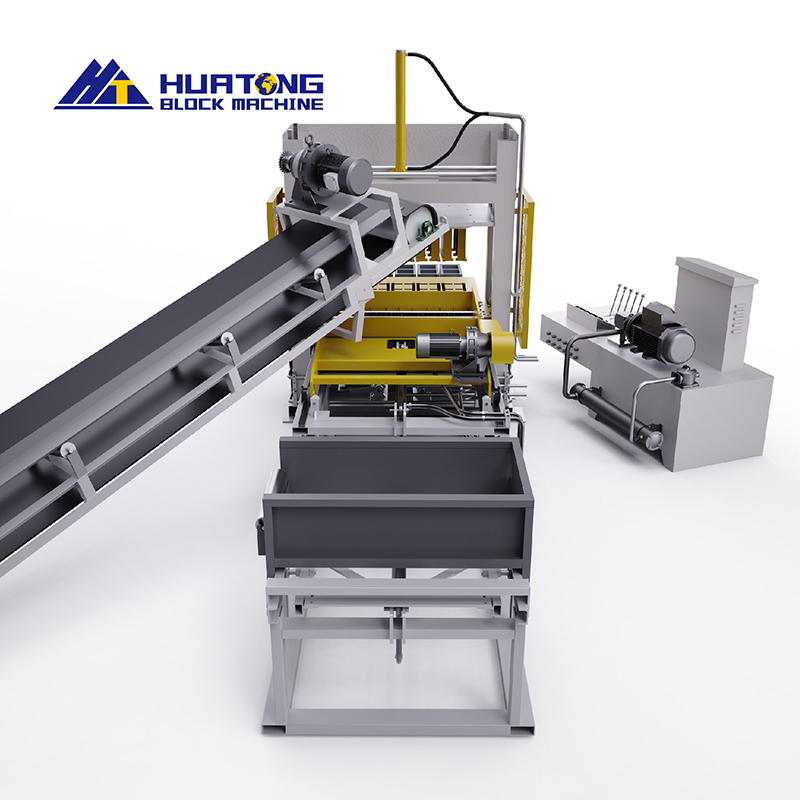

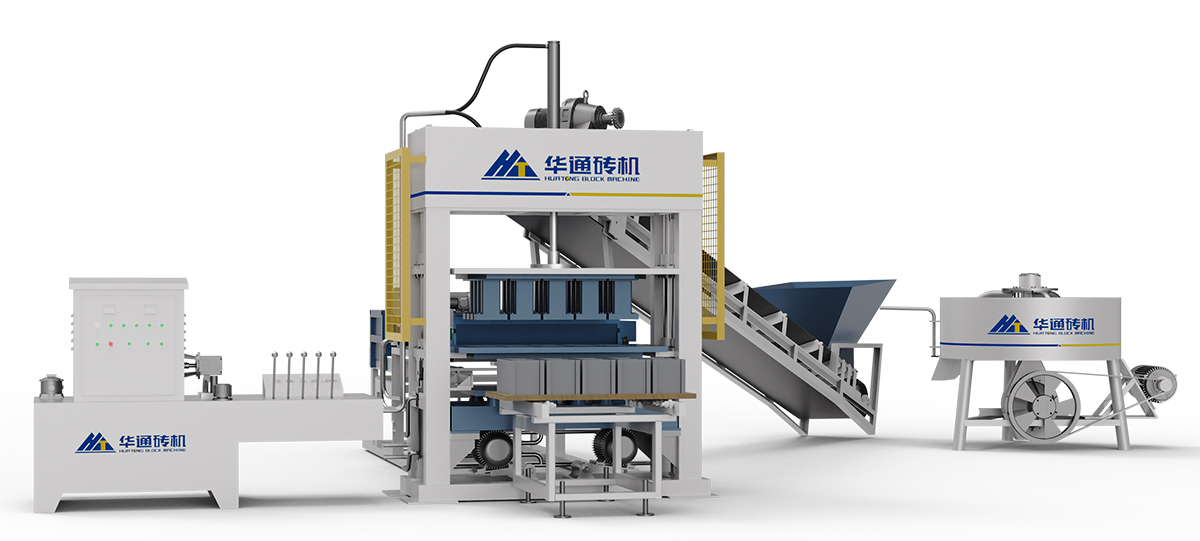

As a professional cement block making machine manufacturer, you can purchase our products with confidence. We guarantee the best after-sales service and prompt delivery for the QT4-15 block making machine. A cement block machine (also known as a cement brick machine, brick machine, block machine, or briquette machine) is a mechanical device used to mix and press materials such as quartz sand, cement, and ash into bricks or blocks of various specifications.

Everyone has their own unique perspective on block forming machines, and our goal is to meet each customer's specific product needs to the greatest extent possible. As a result, our block forming machines have earned widespread recognition and a strong reputation in many countries. Block forming machines use materials such as fly ash, river sand, crushed stone, stone powder, fly ash, waste ceramic slag, smelting slag, and a small amount of cement to produce new wall materials. Most machines utilize hydraulic forming, while some also use vibration forming. Block forming machines can process various new wall materials from industrial waste, including sand, stone, fly ash, slag, ceramsite, and perlite, into bricks of various shapes and sizes. Some machines can also be automated, using electrical systems and computer control to automate the production process. Block forming machines have a wide range of applications and can produce a variety of brick types, including concrete bricks, cement bricks, and red bricks.

Production Capacity of QT4-15Semi-automatic Block Making Machine

Block Type | Picture | Size(L x W x H) | Pcs./ Pallet | Pcs./ Hour | Pcs./ 8Hours |

Hollow Block | 400x200x200mm | 4 | 625 | 5000 | |

Hollow Block | 400x150x200mm | 5 | 780 | 6240 | |

Hourdi Block | 530x160x195mm | 5 | 780 | 6240 | |

Stock Brick | 220x110x70mm | 20 | 4500 | 36000 | |

Paving Block | 200x100x60mm | 16 | 2300 | 18400 | |

Paving Block | 225x112.5x60mm | 14 | 2000 | 16000 |

Technical Parameter of QT4-15Semi-automatic Block Making Machine

Dimension | 2800×1570×2600mm |

Weight | 4500KG |

Pallet Size | 960×630mm |

Power | 19.9KW |

Mode of Vibration | Table Vibration |

Vibration Frequency | 4200r/min |

Vibration Force | 70KN |

Cycle Time | 15-25sec |

National quality certification

Packing and delivery guarantee

FAQ

How many types of cement are available based on the local raw materials available to each customer? Answer: There are six types: Portland cement, ordinary Portland cement, slag Portland cement, pozzolanic Portland cement, fly ash Portland cement, and composite Portland cement. All can be used to make cement bricks.

What after-sales support does the company provide? Answer: One-year warranty (excluding wearing parts), remote guidance, on-site training, and regular follow-up visits.